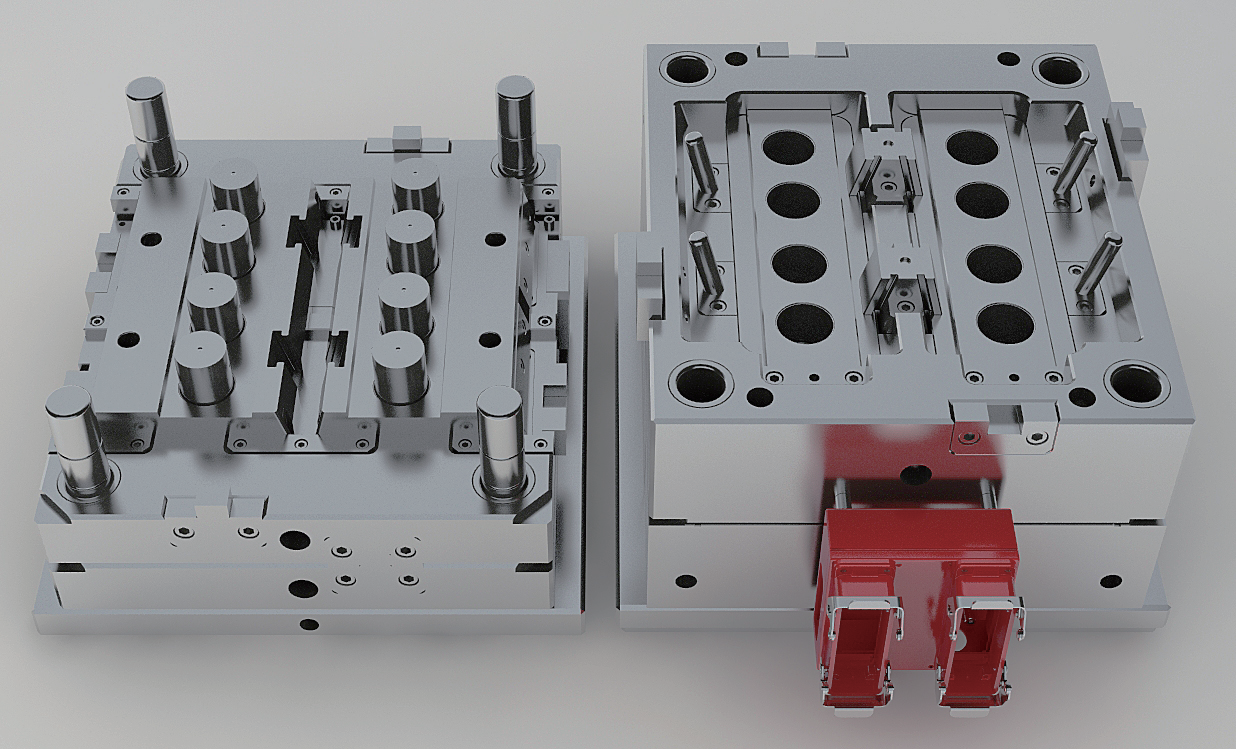

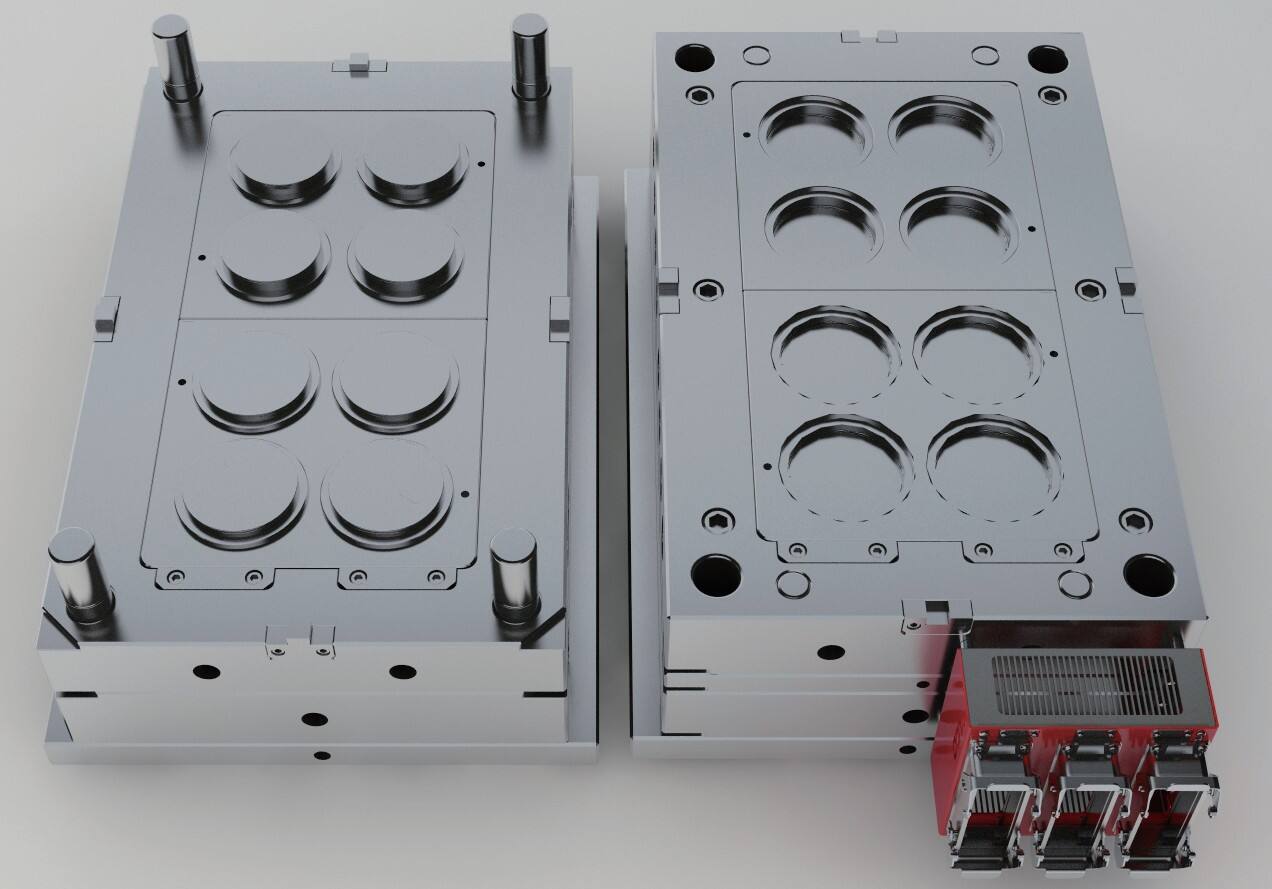

plastic injection molding companies

Plastic injection molding companies are industrial leaders specializing in the manufacturing of precision plastic components through advanced injection molding processes. These companies utilize state-of-the-art machinery and technology to transform raw plastic materials into complex, high-quality products for various industries. The process involves heating plastic pellets until molten, then injecting the material into custom-designed molds under high pressure. These facilities maintain strict quality control measures and employ skilled technicians who oversee the entire production cycle, from initial design to final inspection. Modern injection molding companies integrate computer-aided design (CAD) systems and automated production lines to ensure consistency and efficiency. They offer services including prototype development, tool design, material selection consultation, and high-volume production capabilities. These companies serve diverse sectors including automotive, medical devices, consumer electronics, and packaging industries. They possess the capability to work with a wide range of thermoplastic and thermosetting materials, allowing them to meet specific product requirements for strength, flexibility, temperature resistance, and other physical properties. Advanced facilities also implement sustainable practices, incorporating recycled materials and energy-efficient processes to minimize environmental impact.