small scale injection molding

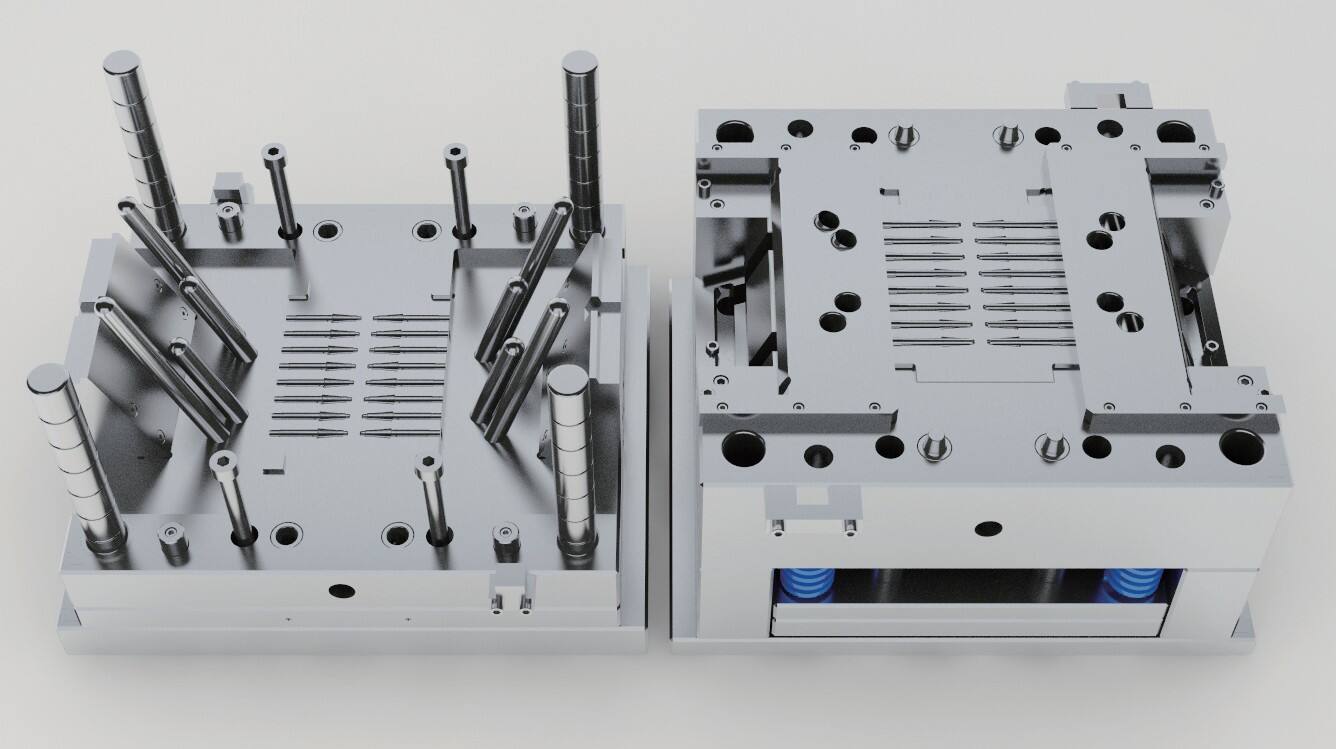

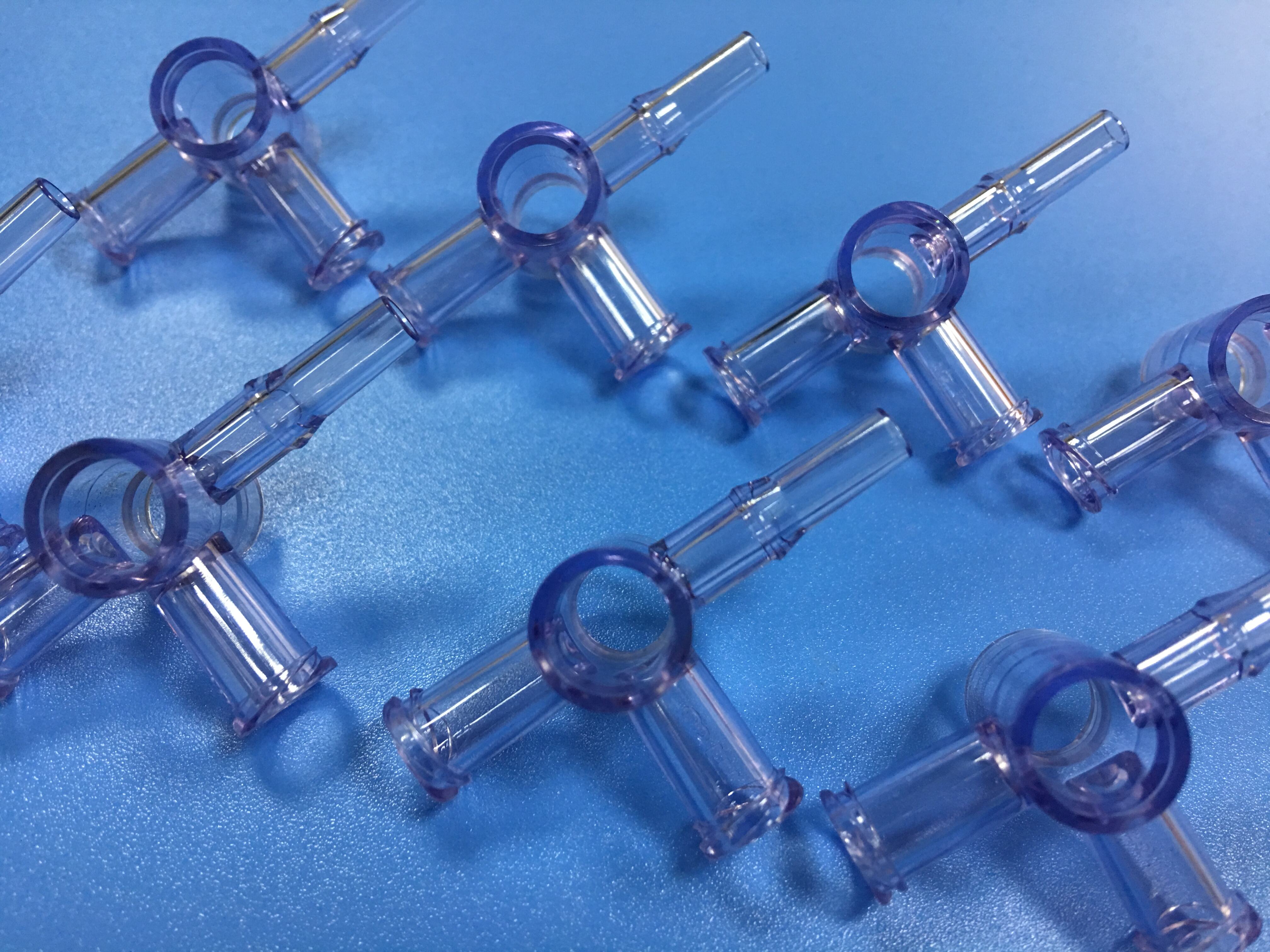

Small scale injection molding represents a cutting-edge manufacturing process designed specifically for producing small plastic parts with exceptional precision and efficiency. This technology utilizes specialized equipment that operates on the same principles as traditional injection molding but is optimized for smaller production runs and miniature components. The process involves melting plastic pellets and injecting the molten material into carefully designed molds under controlled pressure and temperature conditions. What sets small scale injection molding apart is its ability to maintain high precision while working with minimal material quantities, making it ideal for prototyping, small batch production, and specialized applications. The technology incorporates advanced features such as precise temperature control systems, automated material feeding mechanisms, and sophisticated pressure monitoring capabilities. Its applications span across multiple industries, including medical device manufacturing, electronics, automotive components, and consumer products. The process excels in producing intricate parts with complex geometries, tight tolerances, and fine details that would be challenging to achieve through other manufacturing methods. This manufacturing solution particularly benefits startups, research facilities, and companies requiring quick turnaround times for small production volumes.