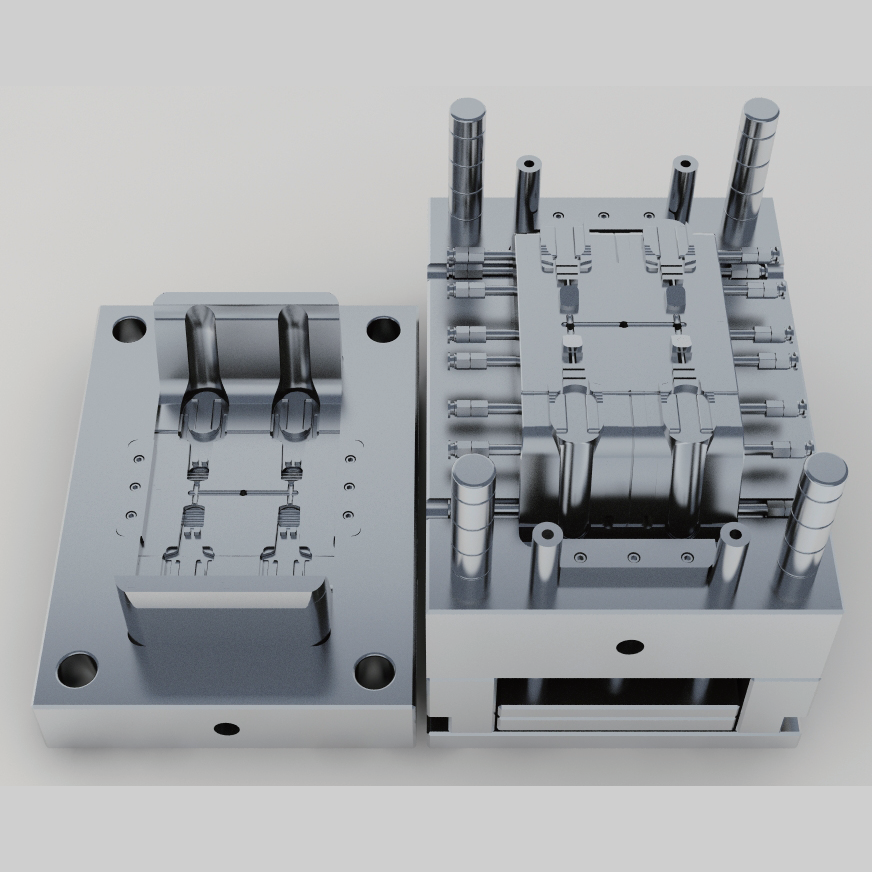

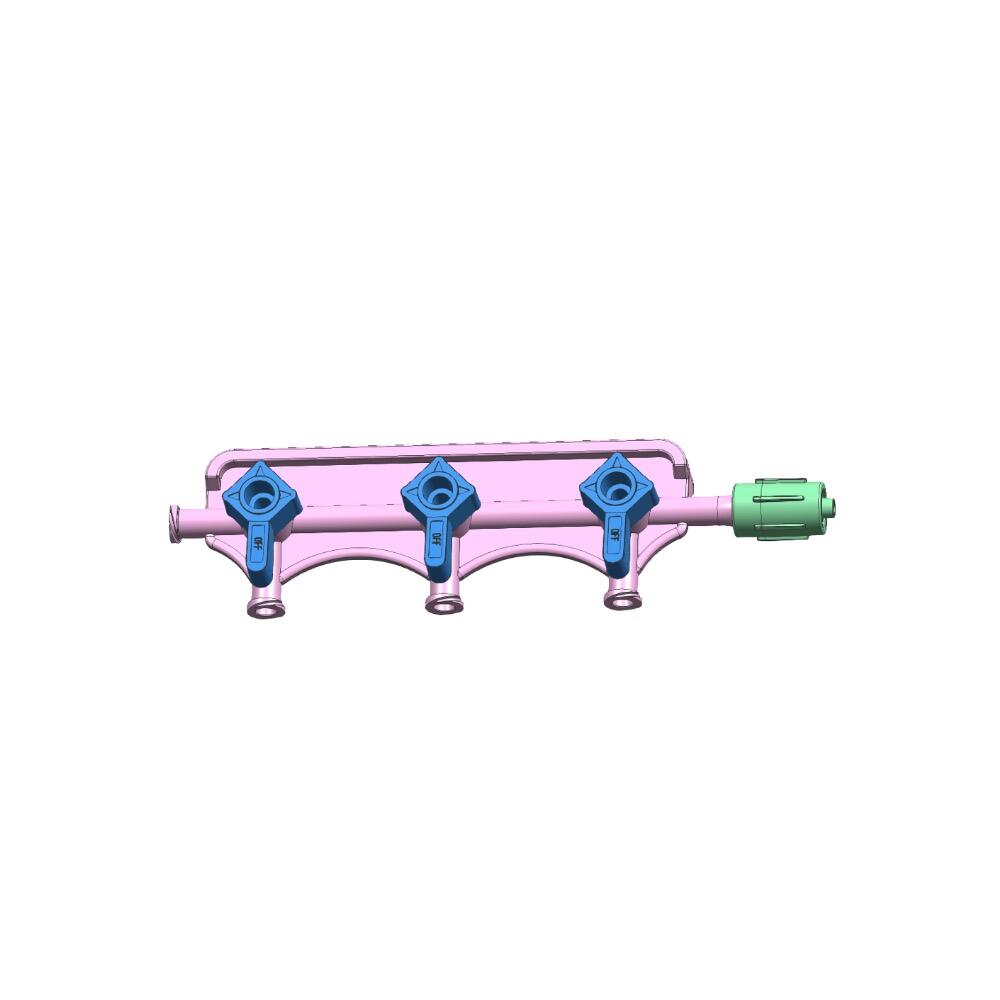

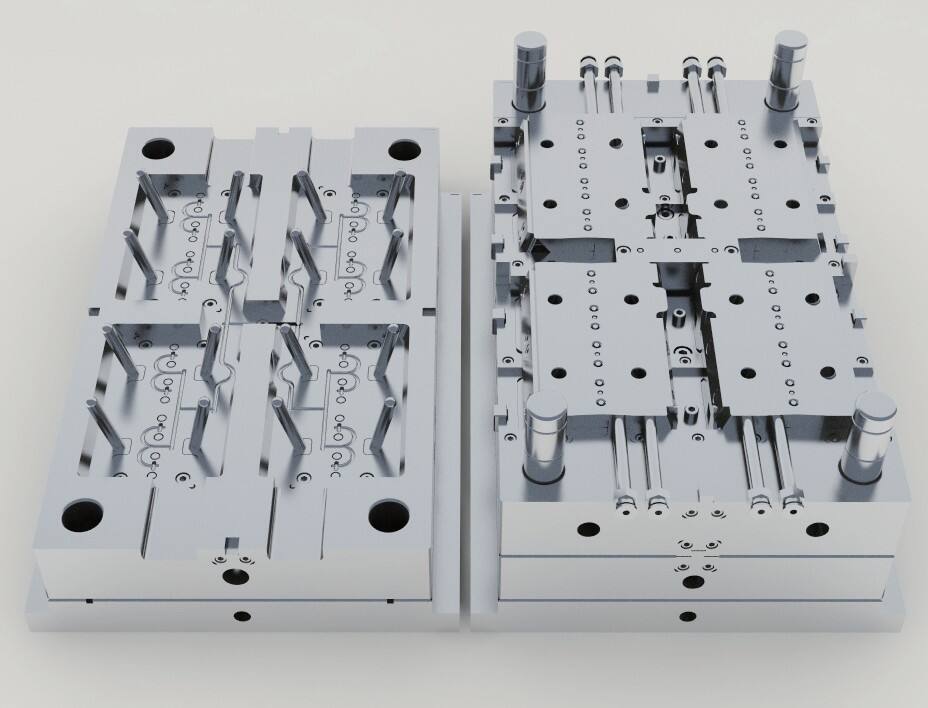

القوالب البلاستيكية للبيع

تُمثِّل قوالب البلاستيك المعروضة للبيع حلول تصنيع متقدمة مصممة لتلبية الاحتياجات الصناعية المتنوعة. يتم تصنيع هذه الأدوات بدقة لإنتاج مكونات بلاستيكية ذات جودة عالية باستمرار من خلال عمليات تشكيل بالحقن. يتضمن نطاقنا الشامل قوالب ذات تجويف واحد، وقوالب متعددة التجاويف، وقوالب عائلية، كل منها مصمم بعناية لتحسين كفاءة الإنتاج وتقليل هدر المواد. تحتوي القوالب على أنظمة تبريد متقدمة تضمن توزيعًا موحدًا للحرارة، مما يؤدي إلى جودة منتجات أفضل وأوقات دورة أقل. من خلال إدراج أنظمة تشغيل ساخنة حديثة، تمكن هذه القوالب من التحكم الدقيق في تدفق المادة وإزالة المسارات الباردة، مما يزيد من فعالية التكلفة في الإنتاج. يتم استخدام بناء قوي من الفولاذ الأداتي عالي الجودة، مما يضمن العمر الطويل والحفاظ على الدقة البعدية طوال التشغيل الإنتاجي المطول. هذه القوالب متوافقة مع مجموعة متنوعة من مواد البلاستيك الحراري ويمكن تخصيصها لتلبية المتطلبات المنتجات المحددة، من المكونات البسيطة إلى الهندسات المعقدة. تحسينات المعالجة السطحية والتغطيات تعزز مقاومة التآكل ومنع الصدأ، مما يمدد عمر القالب ويحافظ على جودة المنتج بشكل مستمر.