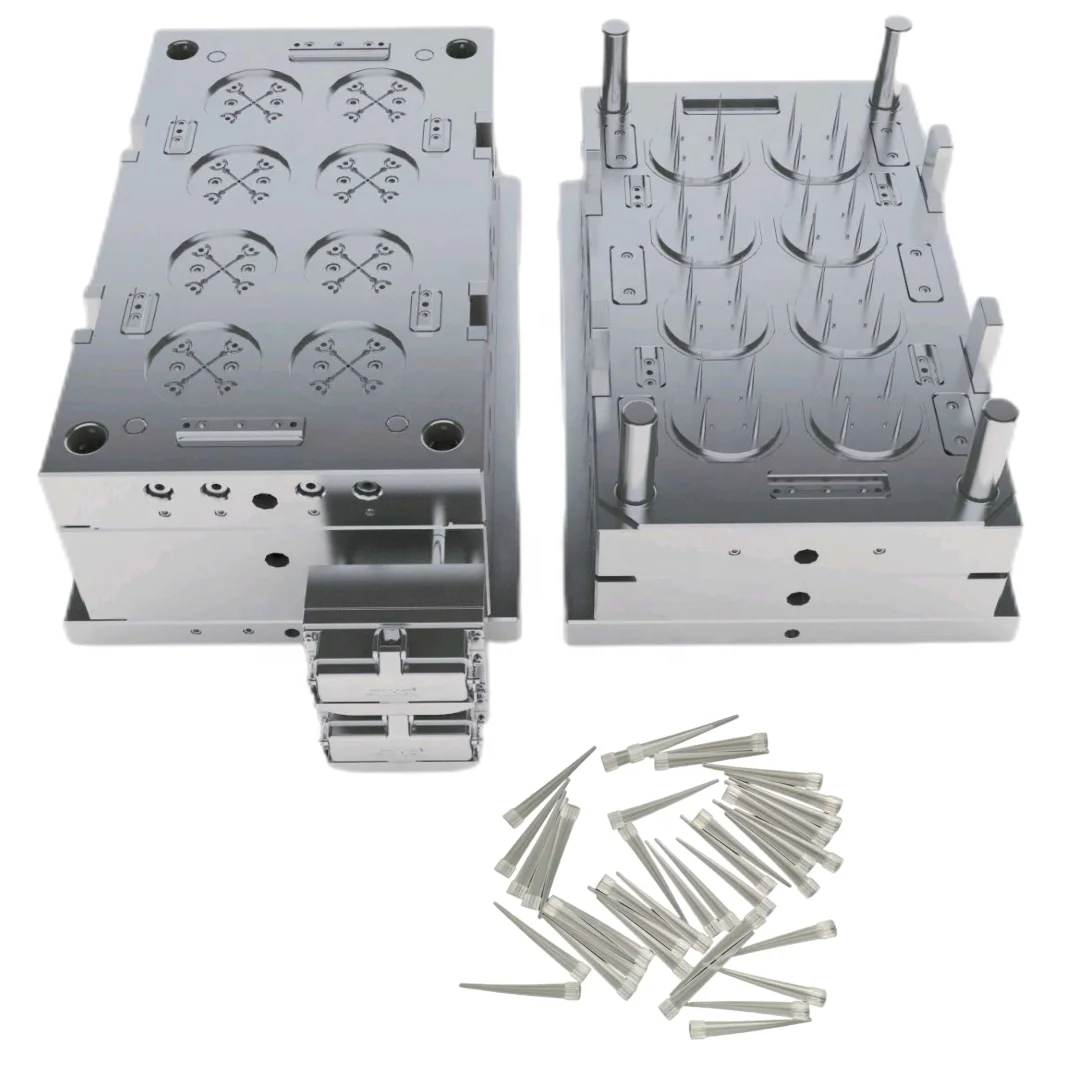

Hot Runner Plastic Laboratory Yellow Pipette Tips 200ul Injection Mold

Constructed from high-quality materials using state-of-the-art injection moulding processes, and meet the high standards required for medical instruments.

- Overview

- Related Products

Description |

Injection mold for pipette tip mold |

Part Material |

All thermoplastics such as ABS, PC, PP, PE, PA, TPE, POM, PPS, PBT and other high engineering plastic, such as PEEK, PPS, PPO, PEI, PES etc |

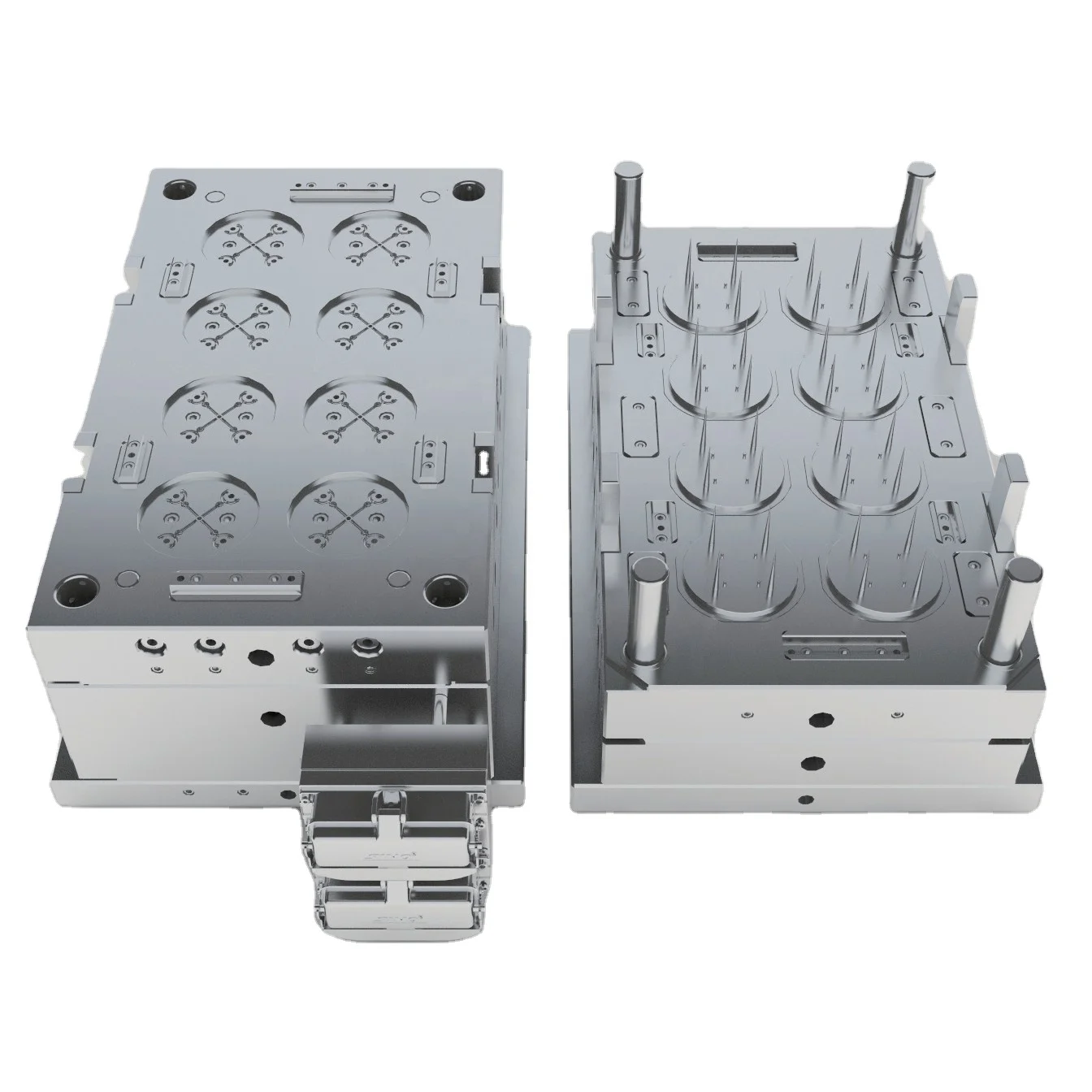

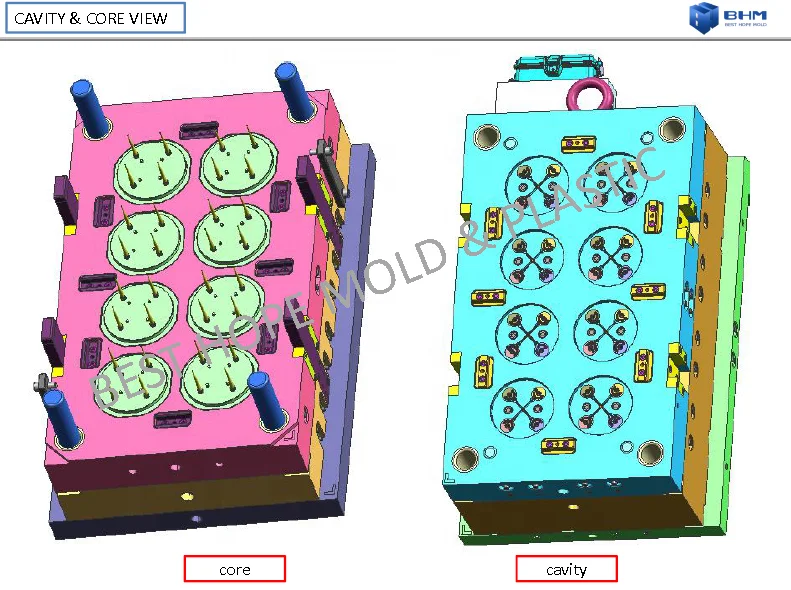

| Cavity number | 4/8/16/32/64...(optional) |

| Runner | Hot runner or cold runner |

| Core & cavity material | S136, 1.2083 stainless steel |

| Mould Standard | MISUMI, DME,CUMSA,HASCO |

| Mould life | Long mold life |

| Available format | .stp/.pdf/.x-t/.step./.dwg/.dxf/.igs/.prt/.stl/.sldprt |

BHM is an ISO 13485 certified contract manufacturer for medical devices.

We offer Plastic Injection Molding in ISO Class 8 clean room environment. Inspection, assembly, and packaging operations also take place in our cleanroom facilities.

BHM has supplied precision injection molded parts and tooling to some of the largest medical device companies in the world.

We’re able to meet the most difficult molding challenges by combining modern scientific molding principles with over 15 years of medical molding experience.

We have experience in minimally invasive devices, surgical instruments, cardiovascular implantation parts etc.

Mold Build

BHM has an experienced team of mold makers and engineers dedicated to build molds in various types to meet the specific tooling needs of our customers. The molds fabricated by BHM range from simple single cavity molds to complex multi-cavity molds, from Pilot Mold to production mold for export.

Out team utilizes the most current and sophisticated technology and equipment in the mold making process, create world class tooling at competitive prices with short lead time.

-CAD/CAM/UG Software

-Mold Flow Analysis

-Mirror EDM Machines

-Precision CNC Machines

-Milling and Drilling Machines

-Grinders

-Engraving/Texture

| Prototyping | Pilot Mold | Production Mold | Production Tooling for Export |

| DFM Engineering Support | DFM Engineering Support | DFM Engineering Support | DFM Engineering Support |

| One Week lead time | Single Cavity Mold | Multi-cavities mold | Multi-cavities mold |

| Quick design test | Mold design | Detailed mold design | Detailed mold design |

| Painting Finishing | 4-6 weeks for T1 | on-site tool shop to handle revisions, mainterance and repairs | Guaranteed tool life of 1 million shorts or more |

| SPI Class 101 and 102 |

Design for manufacturability and efficient production is our primary objective.

With advanced CAD/CAM/CAE systems, such as Pro-E, UG, AutoCAD, mold flow, power milling mold design and analysis, we can provide you different file formats:

STEP,PRT, SLDPRT

X_T, DXF, Etc.

Our sophisticated designing team with decades of experience can provide the most appropriate design manufacturing option for your product and ensures the compliance with your production capacity requirements.

Package:Anti-rust oil is painted first, then Plastic film, and finally wooden case outside

Shipping: PORT OF SHANGHAI

BHM atten medical and plastic exhibitions every year, such as MEDICA in Dusseldorf, Arab Health in Dubai, CMEF in Shanghai, FIME in Miami, Chinaplas, Medtech etc.

We are looking forward to see you at the exhibition!

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q: Where is your factory ?

A: Our factory is located in JIASHAN,ZHEJIANG , Head office is in Shanghai.

Q: How many is the MOQ?

A: Welcome to work with us. Even 1 set mould will also be treated seriously.

Q: How to get the mold price ?

A: We can make quotation according to the photo or 2D/3D drawing.

Q: How can we know whether the mold is good?

A: We will send samples to you by express for confirmation . We also welcome you come here to witness the mold testing, then you can see how the mould is working.

Q: How long is your delivery time?

A: Normally it is 30-50 after receipt of downpayment and also drawing confirmed. It deponds on the mold structure.