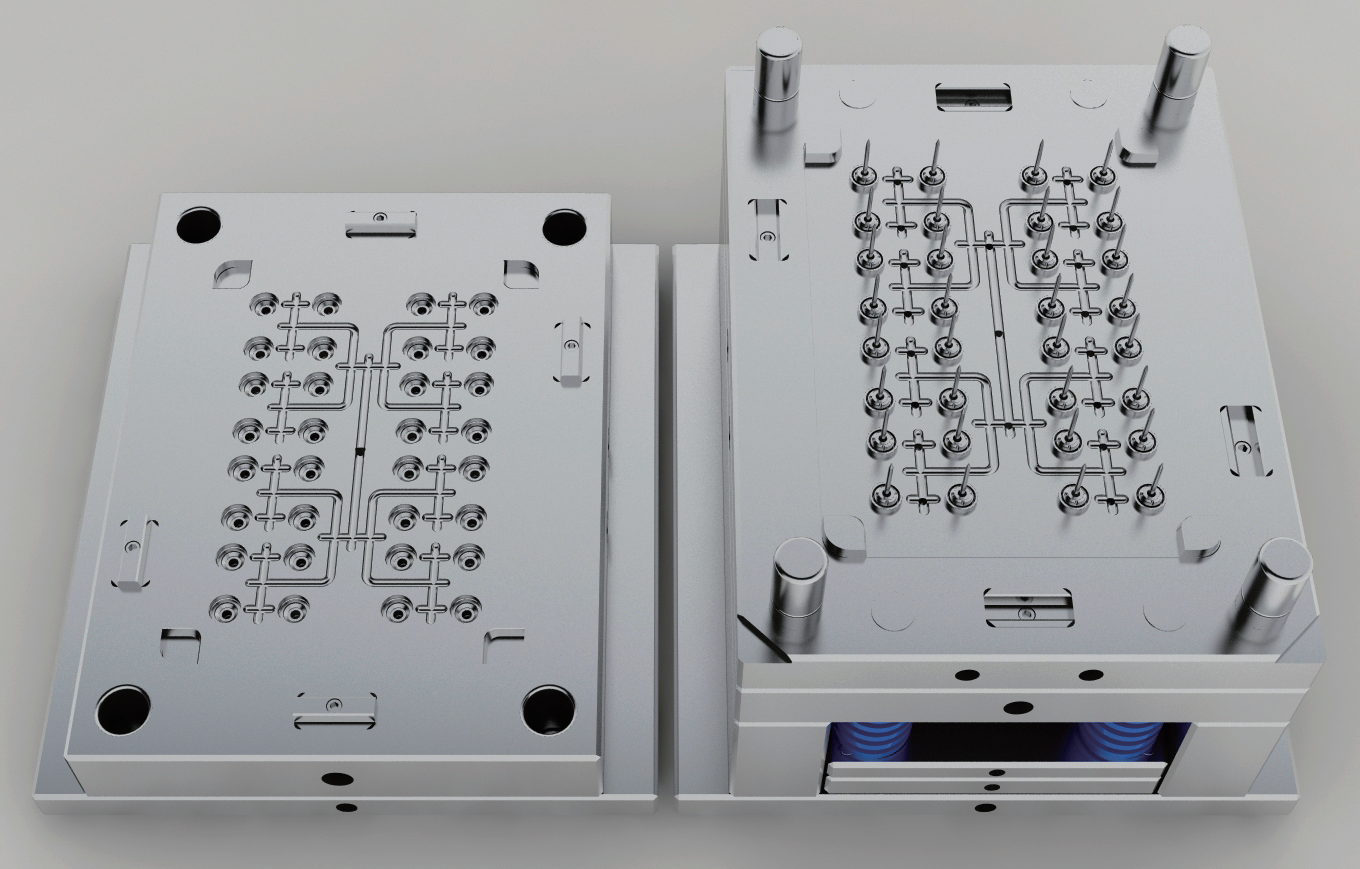

custom plastic injection moulding

Custom plastic injection moulding represents a sophisticated manufacturing process that transforms plastic resin into precisely engineered components through a highly controlled injection system. This versatile technology enables the production of complex plastic parts with exceptional accuracy and consistency. The process begins with melting plastic pellets, which are then injected into carefully designed molds under high pressure. The molten plastic fills every cavity and detail of the mold, creating exact replicas of the desired component. What sets custom injection moulding apart is its ability to accommodate specific requirements, from material selection to design modifications. The technology incorporates advanced features such as temperature control systems, precision hydraulic or electric injection units, and sophisticated cooling mechanisms. These elements work in harmony to ensure optimal product quality and consistency. The applications span numerous industries, including automotive, medical devices, consumer electronics, and household products. Modern injection moulding systems often integrate smart manufacturing capabilities, allowing real-time monitoring and adjustment of production parameters. This technology proves particularly valuable for projects requiring high volume production while maintaining strict quality standards and complex geometries.