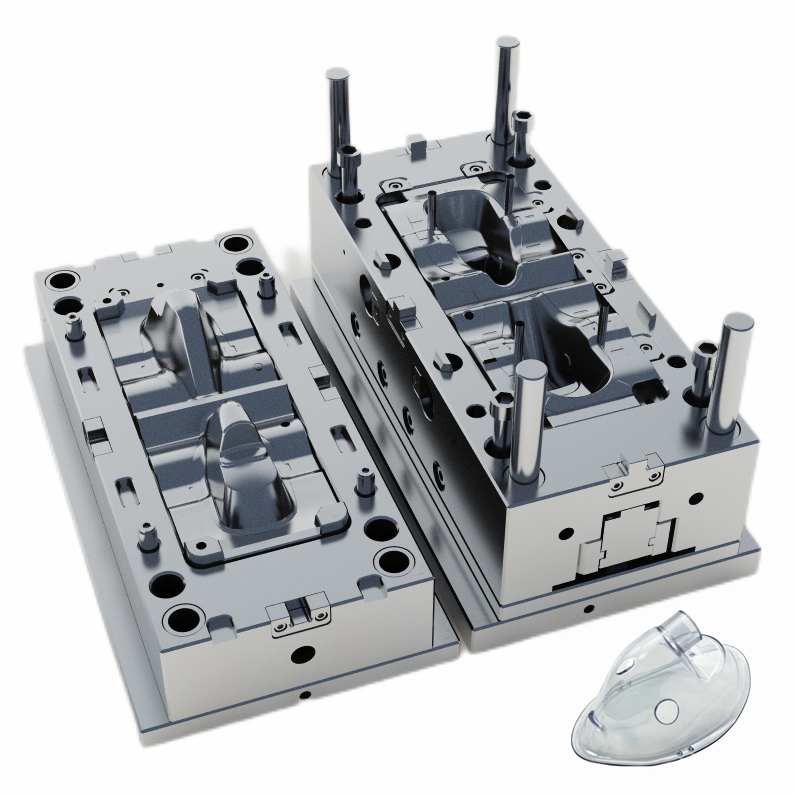

plastic molding services

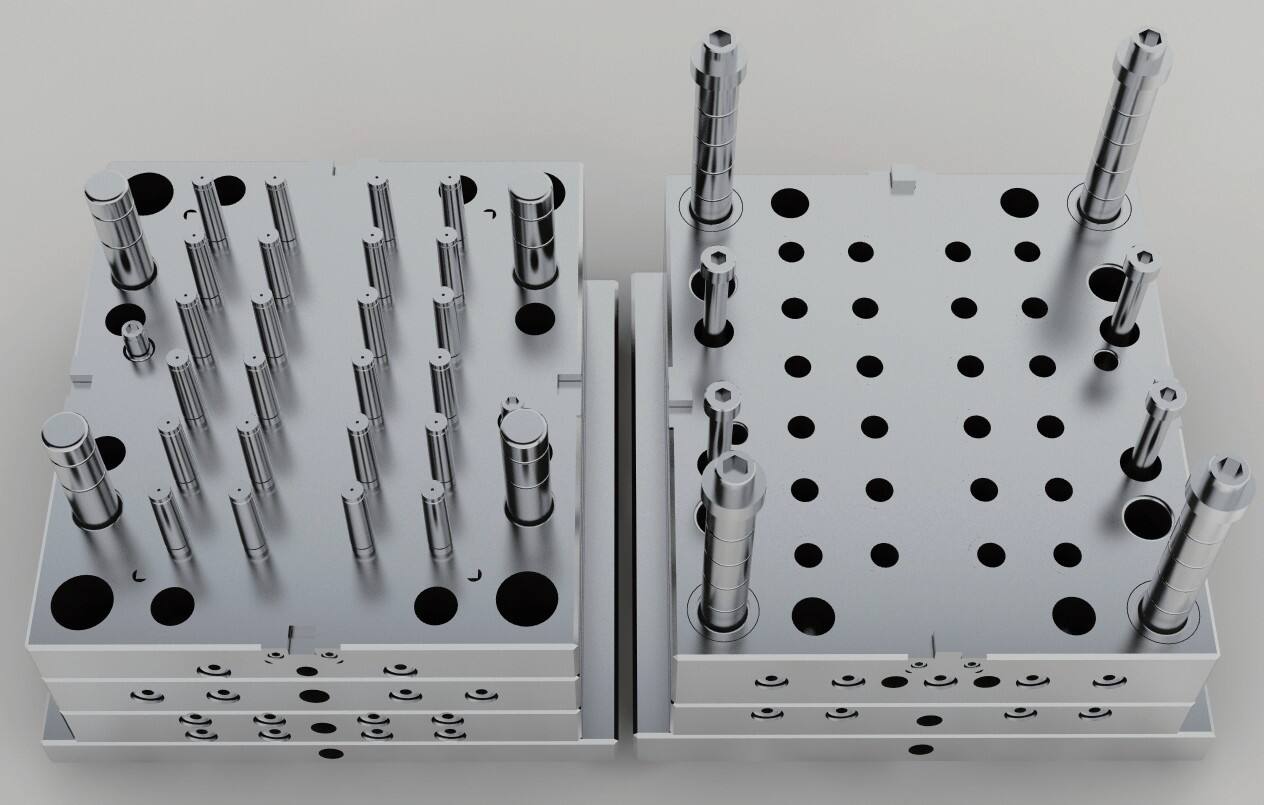

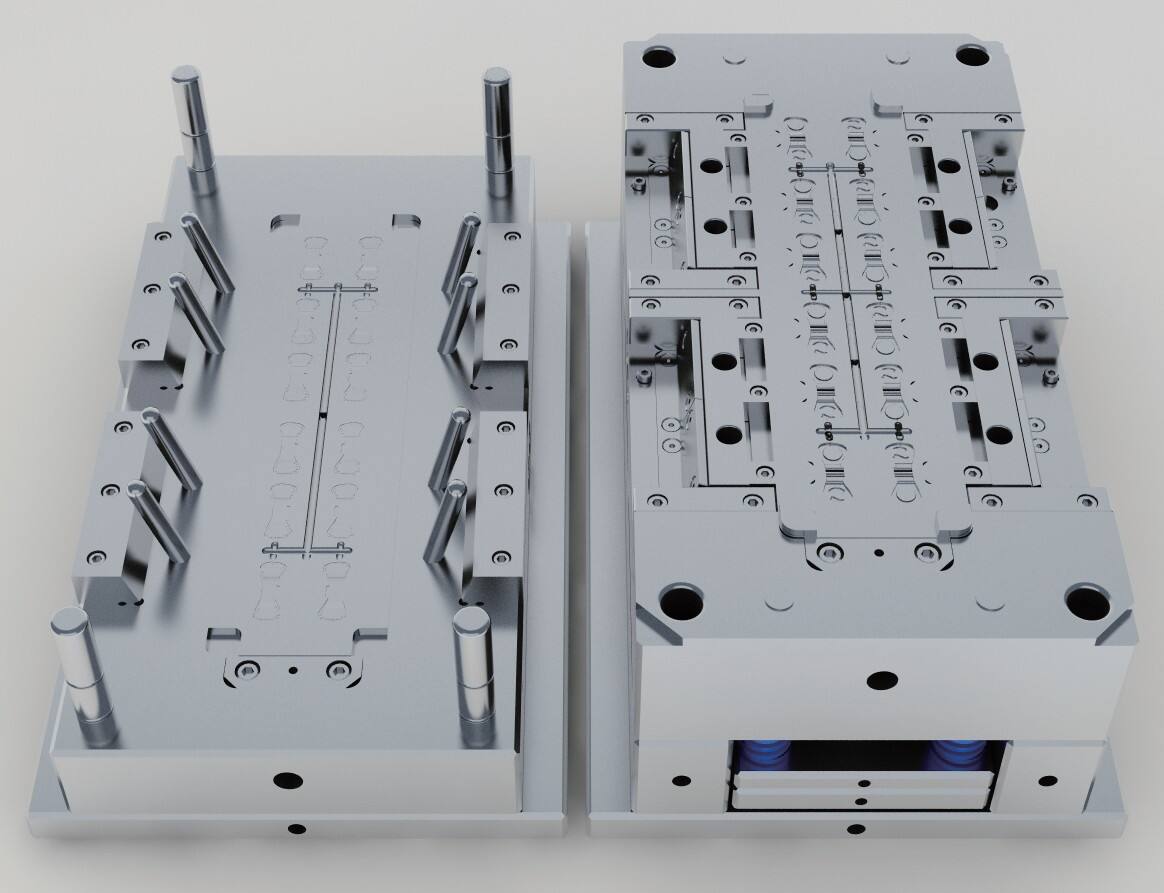

Plastic molding services represent a comprehensive manufacturing solution that transforms raw plastic materials into precise, custom-designed products through various molding processes. This sophisticated manufacturing method employs advanced technology and equipment to create complex plastic components with exceptional accuracy and consistency. The process begins with carefully selected polymer materials that are heated to their melting point and then injected, compressed, or blown into precisely engineered molds. These services accommodate diverse production scales, from small prototype runs to high-volume manufacturing operations, making them versatile for different industry needs. The technology incorporates computer-aided design (CAD) systems, automated quality control mechanisms, and precision tooling to ensure each produced component meets exact specifications. Notable applications span across multiple sectors, including automotive parts manufacturing, consumer electronics, medical device production, packaging solutions, and aerospace components. The service encompasses various techniques such as injection molding, blow molding, compression molding, and rotational molding, each optimized for specific product requirements and material characteristics. Modern plastic molding services also integrate sustainable practices, offering options for using recycled materials and implementing energy-efficient production methods to meet environmental responsibilities.