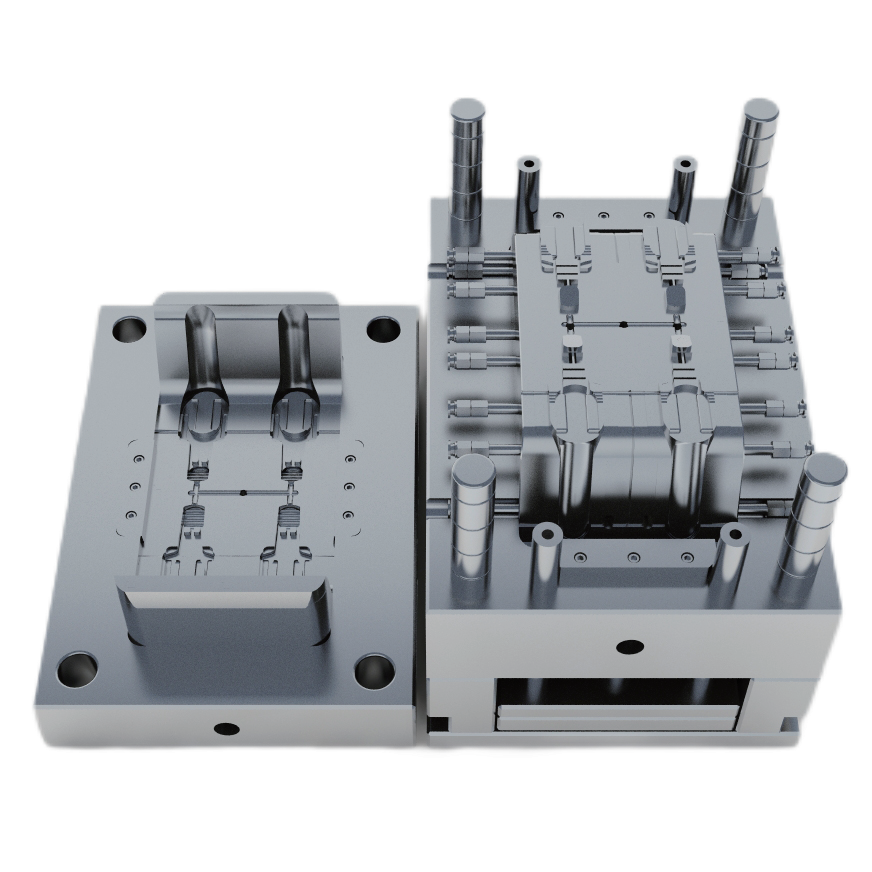

injection part

The injection part represents a critical component in modern manufacturing and industrial processes, serving as an essential element in the precision delivery of materials. This sophisticated component is engineered to ensure accurate material distribution through carefully calibrated channels and precision-controlled mechanisms. At its core, the injection part features advanced flow control technology that enables precise material dispensing, while incorporating wear-resistant materials to maintain long-term reliability. The component's design includes specialized nozzles, carefully engineered chambers, and precise control mechanisms that work in harmony to achieve optimal material flow and distribution. In industrial applications, the injection part plays a vital role in various sectors, from automotive manufacturing to medical device production, where precise material delivery is paramount. The component's versatility allows it to handle different material viscosities and flow rates, making it suitable for diverse manufacturing requirements. Its integration with modern control systems enables real-time monitoring and adjustment of injection parameters, ensuring consistent quality in production processes.