medical mold price

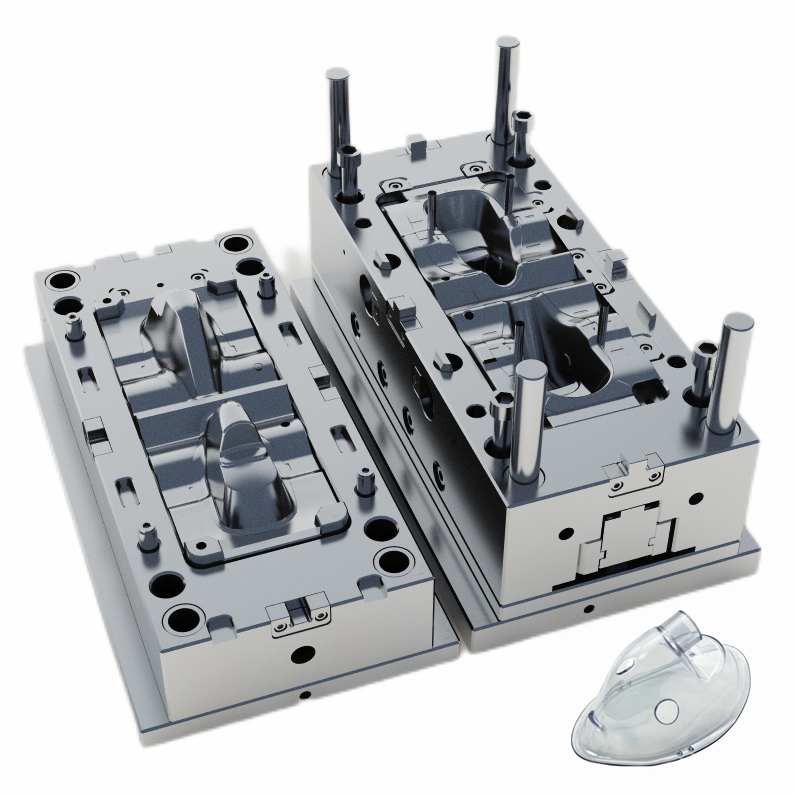

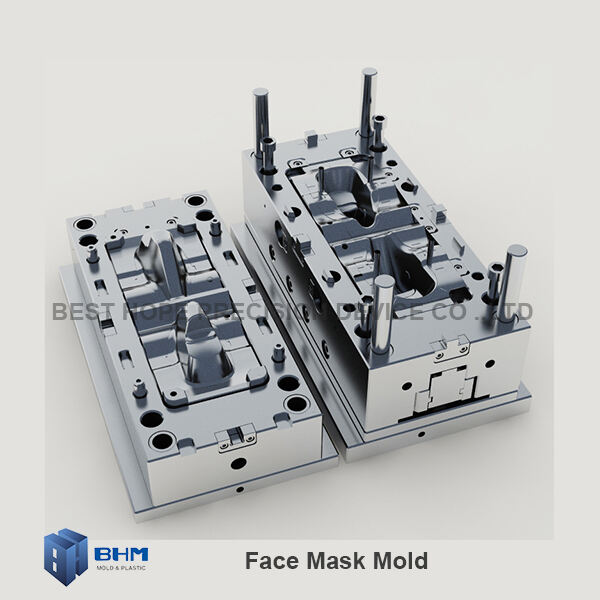

Medical mold pricing represents a crucial aspect of healthcare manufacturing, encompassing the complex process of creating precision tools for medical device production. The cost structure typically includes material selection, design complexity, manufacturing precision, and production volume considerations. High-grade materials such as medical-grade stainless steel and specialized polymers contribute significantly to the overall price, ensuring compliance with stringent healthcare regulations. Modern medical molds incorporate advanced features like multi-cavity designs, hot runner systems, and precise temperature control mechanisms, which influence the final pricing. The cost analysis must account for validation processes, documentation requirements, and quality control measures specific to medical device manufacturing. Manufacturers must consider both initial tooling investments and long-term production efficiency when evaluating medical mold prices. The pricing structure also reflects the sophisticated engineering required for maintaining strict tolerances, clean room compatibility, and regulatory compliance. Understanding medical mold pricing helps healthcare manufacturers optimize their production costs while maintaining the highest quality standards for medical devices.