plastic injection molding price

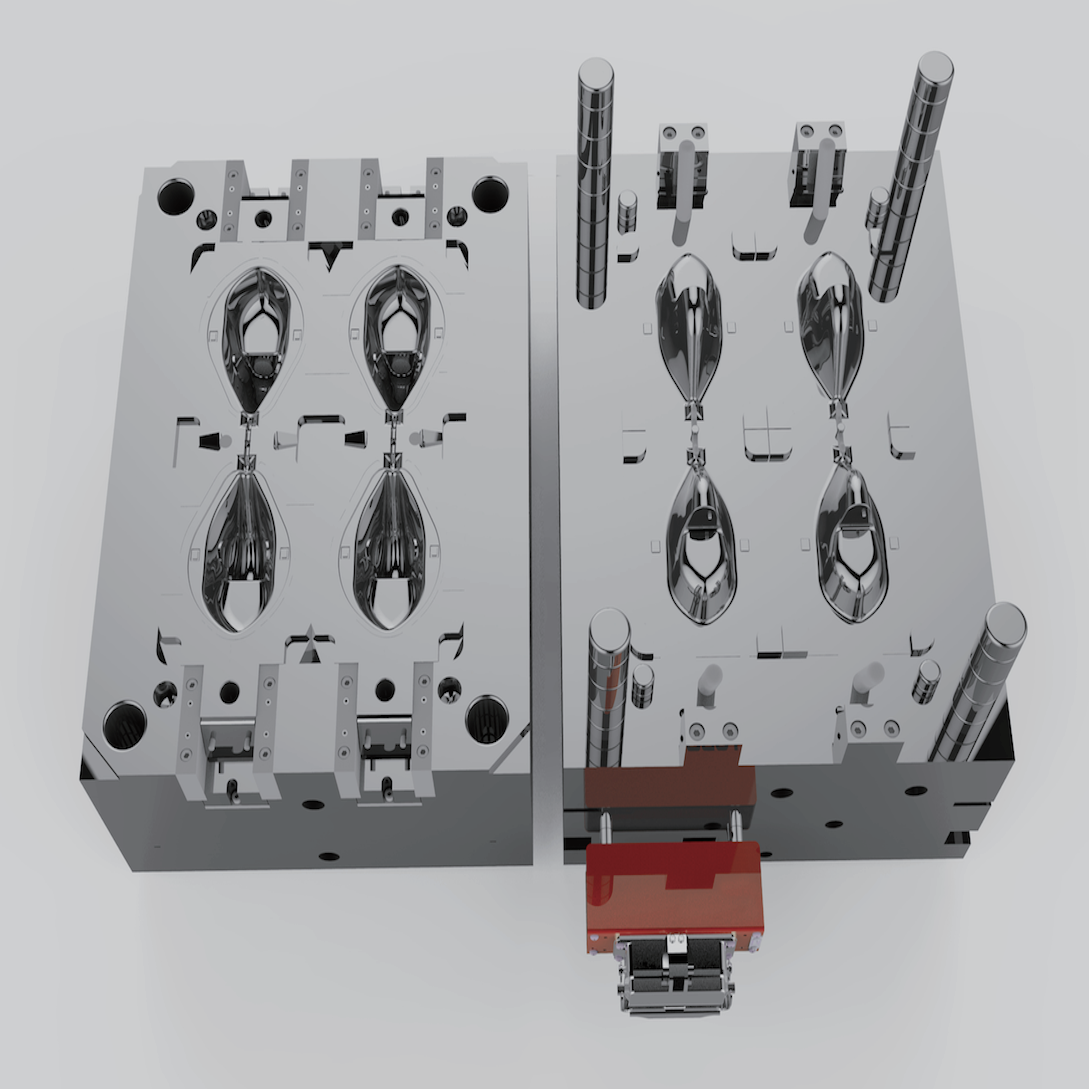

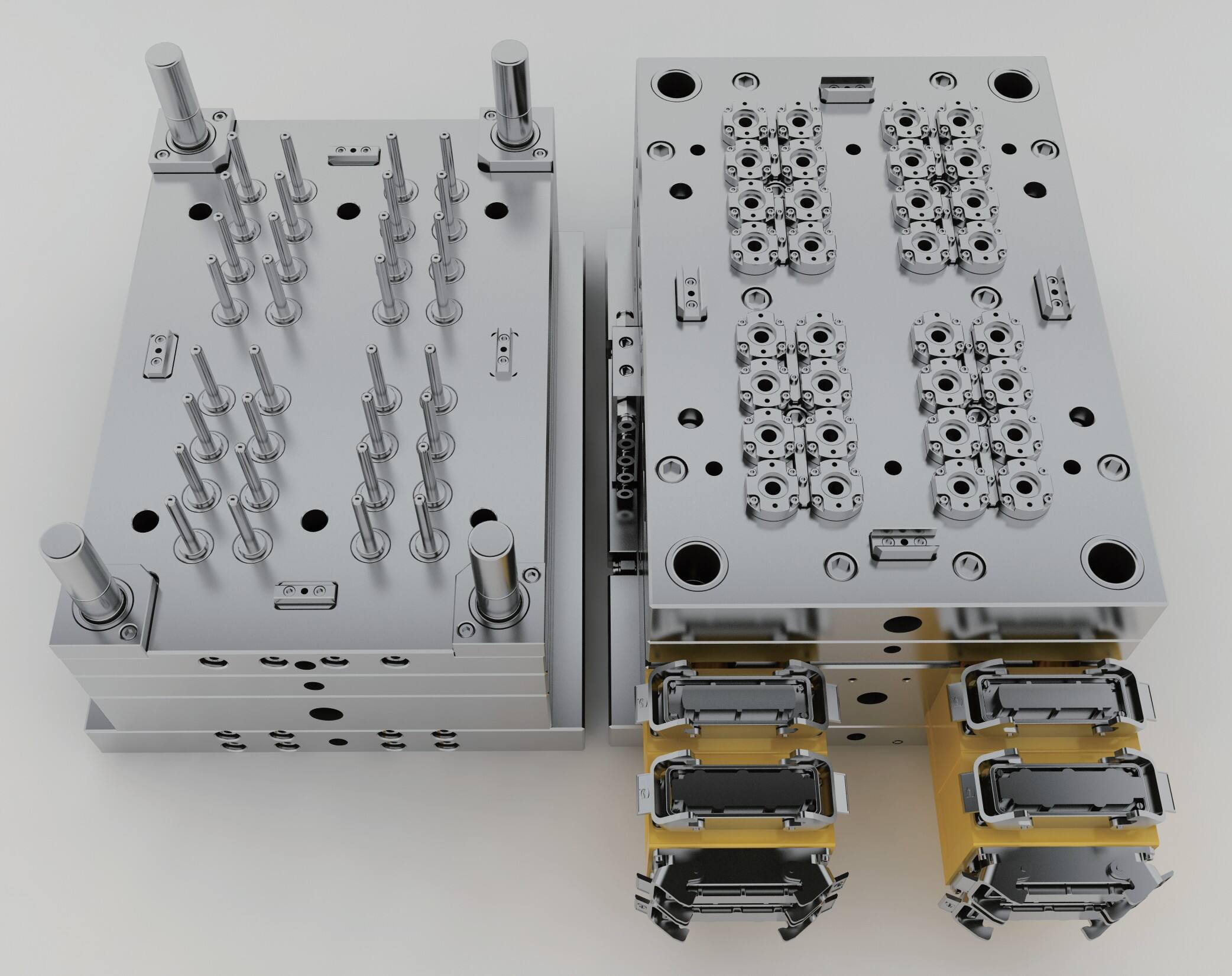

The plastic injection molding price encompasses various factors that determine the cost of manufacturing plastic components through injection molding. This manufacturing process involves injecting molten plastic material into a mold cavity under high pressure, where it cools and solidifies into the desired shape. The price structure typically includes initial tooling costs, material expenses, production volume considerations, and operational overhead. Modern injection molding technology utilizes advanced computer-controlled systems to ensure precise temperature control, pressure monitoring, and timing sequences, resulting in consistent product quality. The pricing model considers factors such as part complexity, material selection, surface finish requirements, and production quantity. This versatile manufacturing method serves industries ranging from automotive and consumer goods to medical devices and electronics. The technological features incorporated in current injection molding systems include automated material handling, real-time quality monitoring, and sophisticated cooling systems that optimize cycle times. Understanding the price components helps businesses make informed decisions about their manufacturing processes, considering both immediate costs and long-term value.