injection molding automotive parts

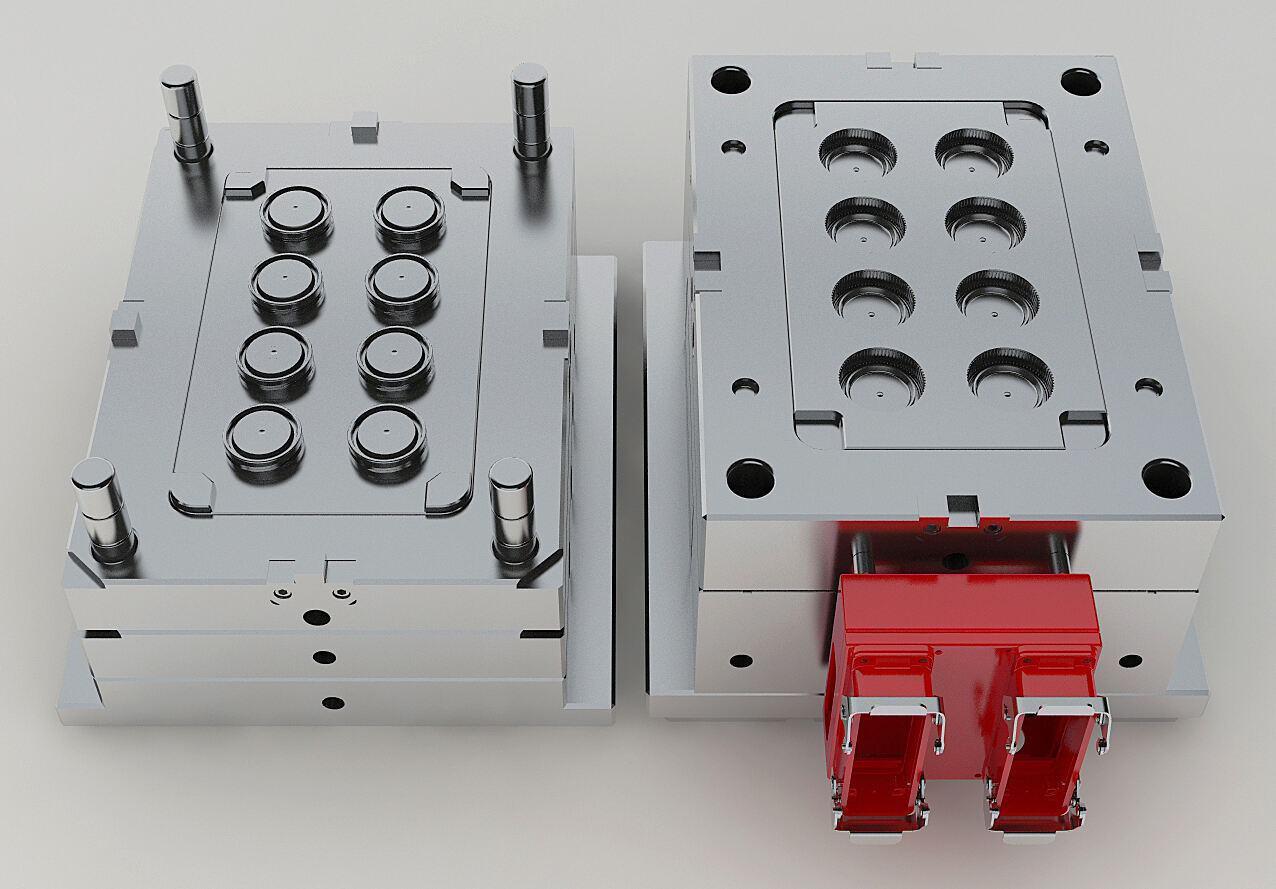

Injection molding automotive parts represent a cornerstone of modern vehicle manufacturing, offering a precise and efficient method for producing high-quality components. This manufacturing process involves injecting molten materials, typically thermoplastic polymers, into carefully designed molds under high pressure. The technology enables the production of complex geometric shapes with exceptional consistency and dimensional accuracy. These parts are integral to both interior and exterior vehicle components, including dashboards, door panels, bumpers, grilles, and various functional components. The process accommodates a wide range of materials, from standard plastics to high-performance engineering polymers, allowing manufacturers to meet specific requirements for strength, durability, and heat resistance. Advanced injection molding systems incorporate sophisticated controls for temperature, pressure, and timing, ensuring optimal part quality and minimal waste. The versatility of injection molding enables the production of parts ranging from small clips and fasteners to large body panels, all while maintaining strict quality standards and meeting automotive industry specifications.