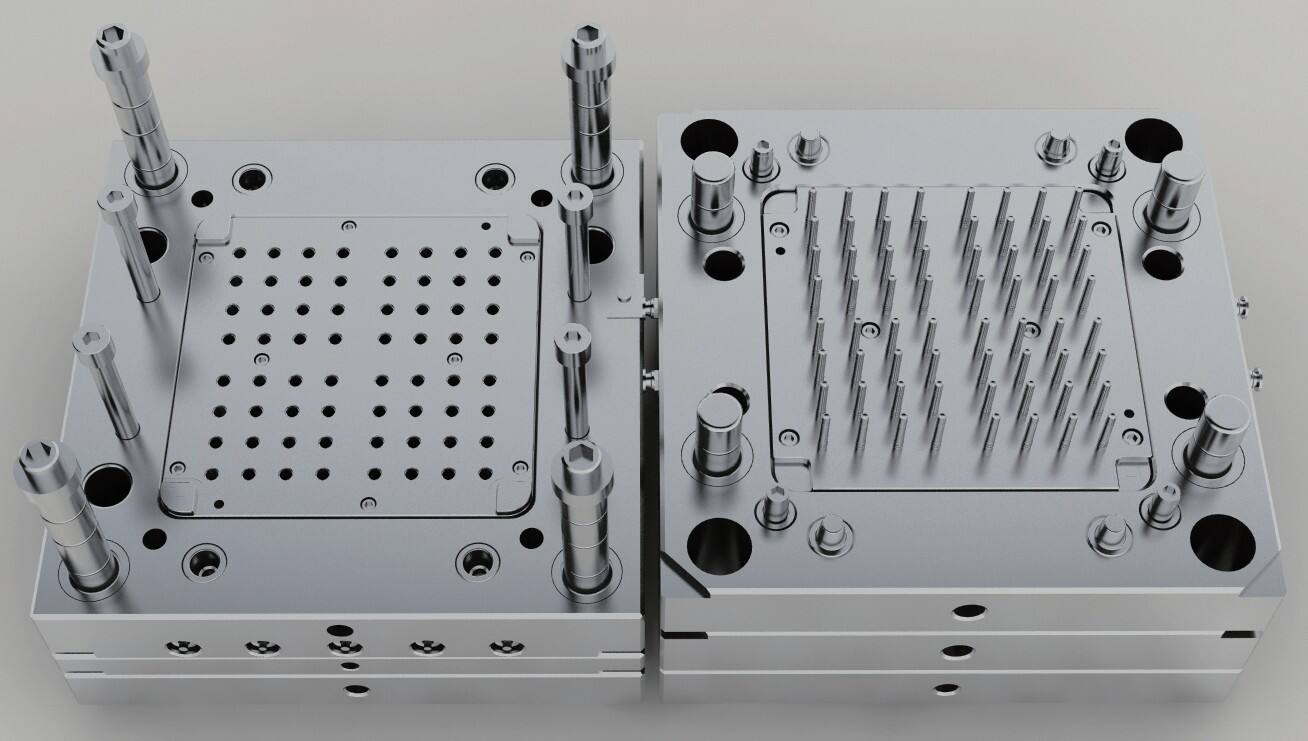

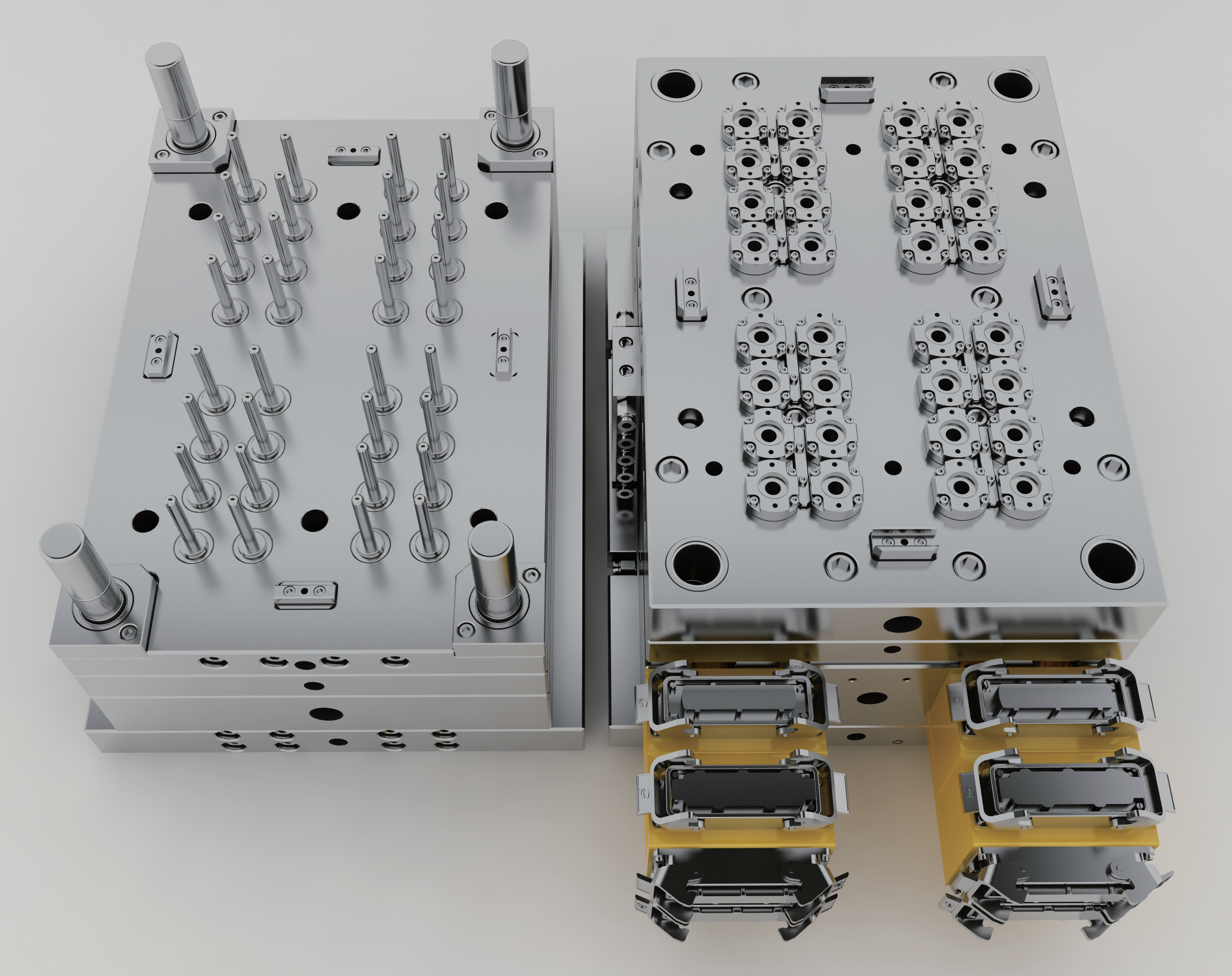

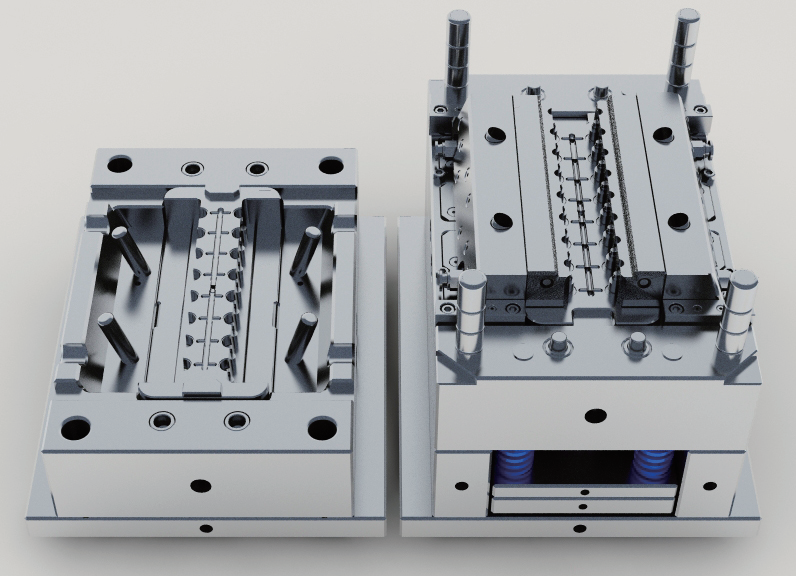

plastic mould maker

A plastic mould maker is a sophisticated manufacturing system designed to create precision tooling for plastic injection molding processes. This advanced equipment combines cutting-edge CNC technology with robust mechanical engineering to produce high-quality molds for various plastic components. The system incorporates multiple axes of movement, allowing for intricate detail work and complex geometrical shapes. It features precision control systems that maintain tolerances down to micrometers, ensuring exceptional accuracy in mold creation. The machine operates through a combination of computer-aided design (CAD) integration and automated tooling processes, enabling seamless translation of digital designs into physical molds. Modern plastic mould makers are equipped with advanced cooling systems to maintain optimal temperature during operation, preventing material deformation and ensuring consistent quality. These machines can handle various materials including hardened steel, aluminum, and copper alloys, making them versatile for different mold requirements. The system's intelligent software interface allows for real-time monitoring and adjustments, while built-in quality control mechanisms ensure each mold meets strict manufacturing standards.