molds for plastic

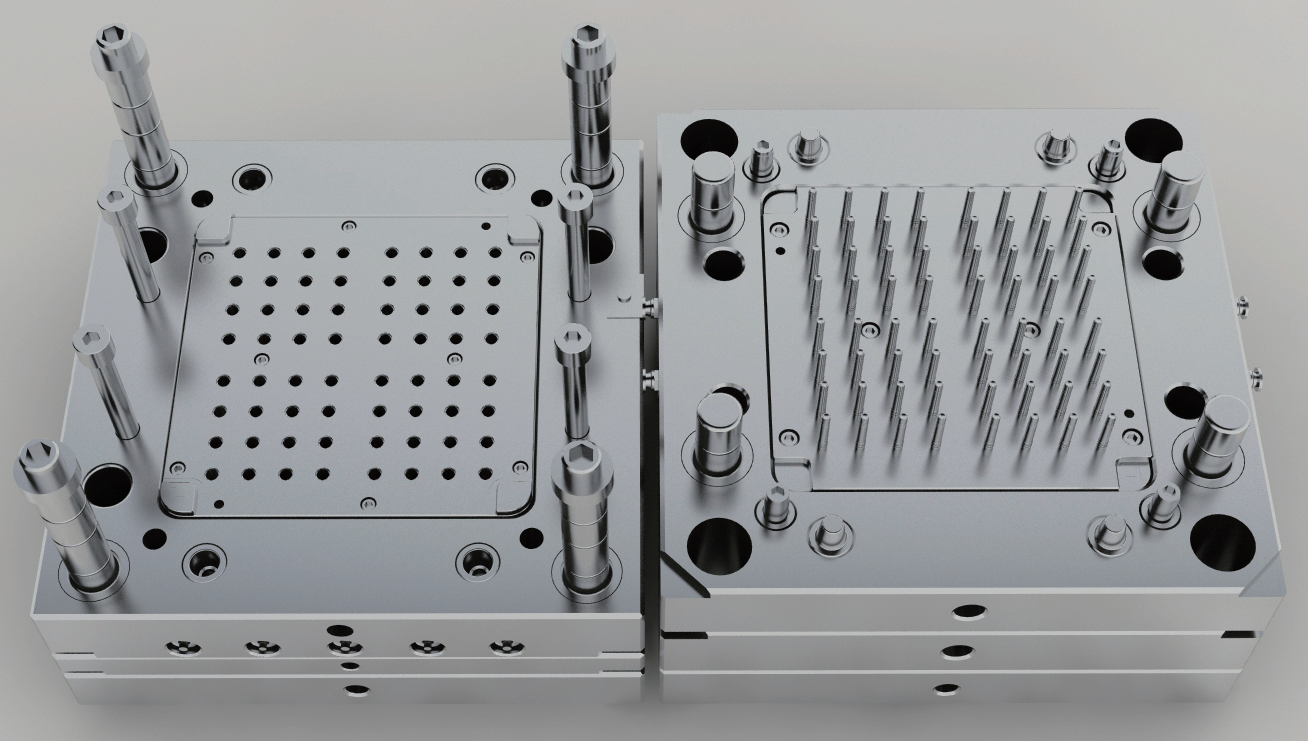

Molds for plastic represent essential tools in modern manufacturing, serving as the cornerstone of plastic product production. These precision-engineered devices create three-dimensional plastic products through various molding processes, including injection molding, blow molding, and compression molding. The molds consist of multiple components, including the cavity, core, cooling channels, and ejection system, each playing a crucial role in the manufacturing process. The cavity and core form the external and internal shapes of the product, while cooling channels regulate temperature for optimal material flow and solidification. Modern molds incorporate advanced features such as conformal cooling systems, which ensure uniform temperature distribution and reduced cycle times. The ejection system facilitates smooth product removal without damage. These molds accommodate various plastic materials, from thermoplastics to thermosets, and can produce parts ranging from simple components to complex assemblies. The technology behind plastic molds continues to evolve, with innovations in design software, materials, and manufacturing techniques enabling increased precision, efficiency, and sustainability in production processes.