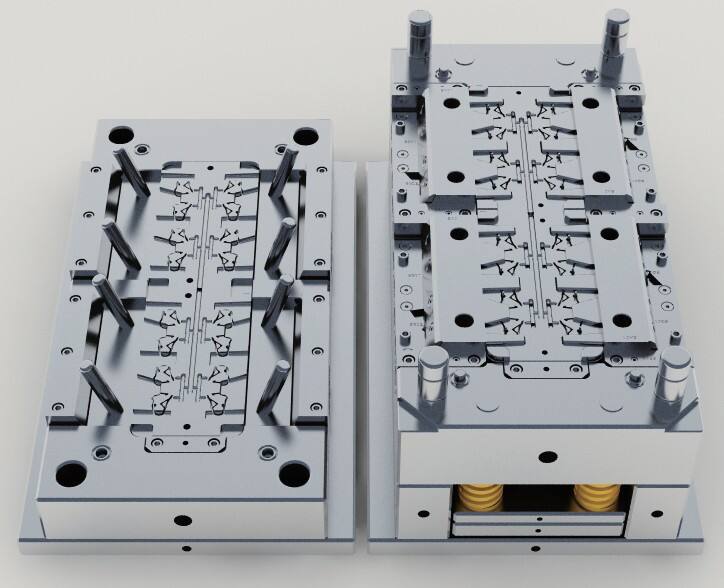

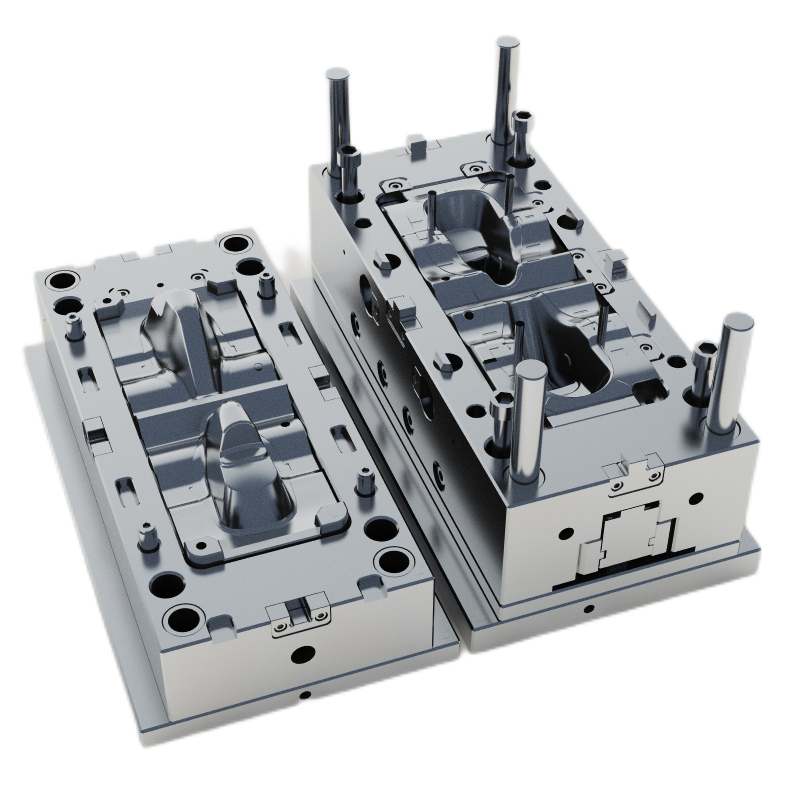

prototype and plastic mold

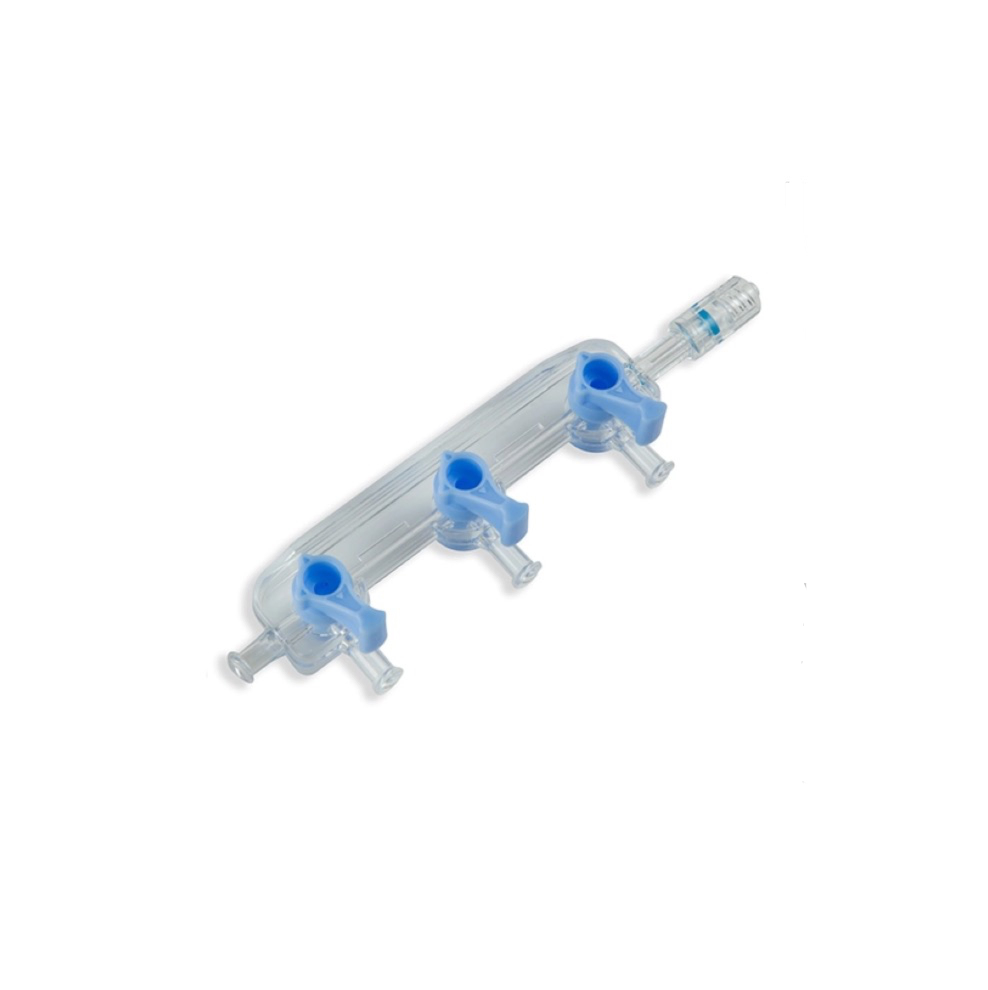

Prototype and plastic mold technology represents a cornerstone in modern manufacturing, combining precision engineering with efficient production methods. This integrated system encompasses both the initial prototype development and subsequent mold creation for mass production. The prototype phase involves creating accurate physical representations of designed products using advanced 3D printing and CNC machining techniques, allowing for thorough testing and validation before full production begins. The plastic mold component utilizes high-grade steel materials and sophisticated cooling systems to ensure consistent, high-quality production outputs. These molds are engineered with precise cavity designs, optimized gate locations, and carefully calculated runner systems to guarantee uniform material flow and optimal part quality. The technology incorporates advanced features such as conformal cooling channels, which maintain consistent temperature distribution throughout the molding process, and ejection systems that ensure smooth part removal without damage. This comprehensive solution finds applications across various industries, including automotive, consumer electronics, medical devices, and household products, offering scalability from prototype testing to full-scale manufacturing operations.