plastic mold price

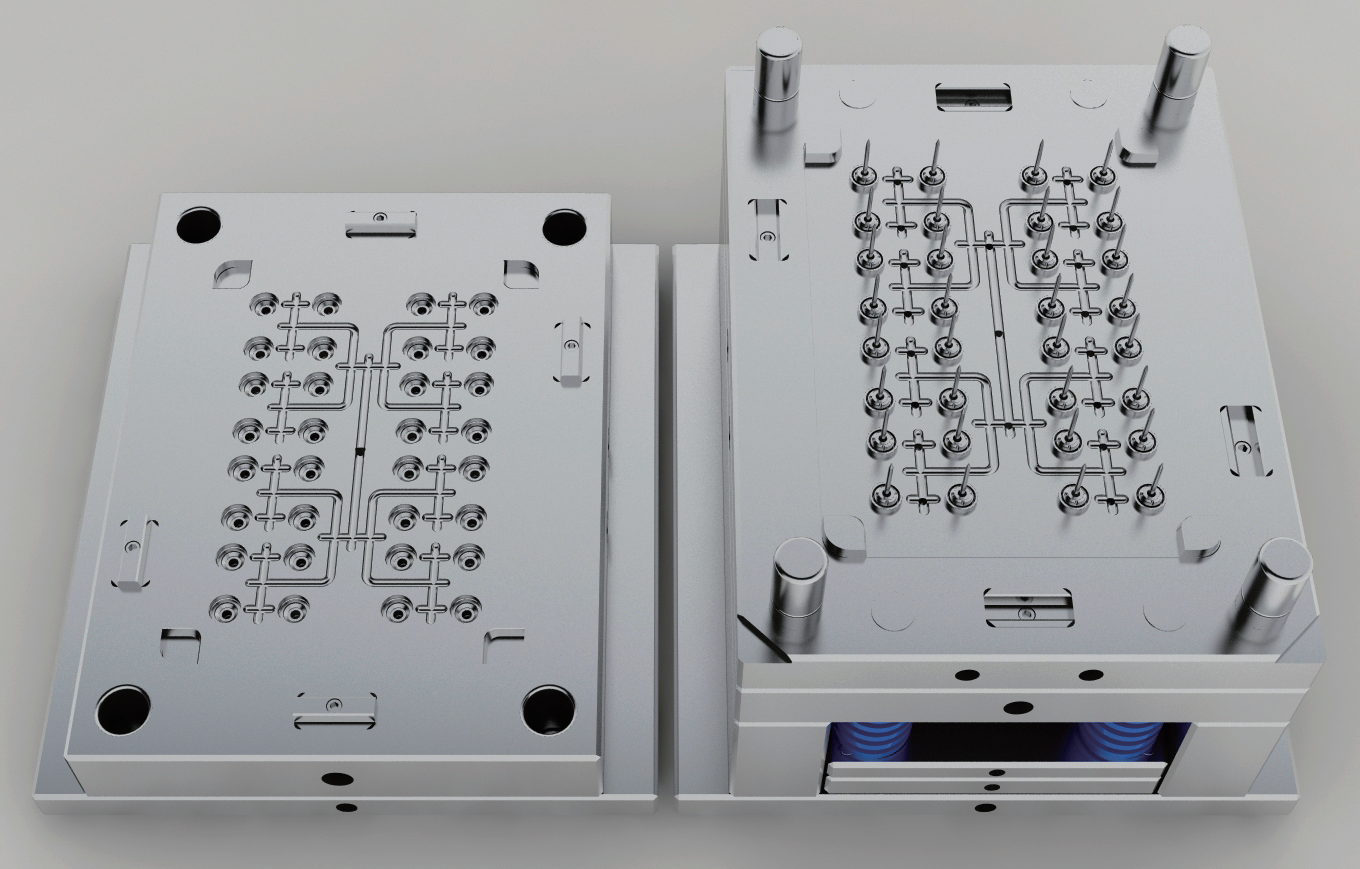

Plastic mold pricing represents a critical aspect of manufacturing that encompasses various factors including design complexity, material selection, production volume, and technological requirements. The cost structure typically includes the initial design phase, material procurement, manufacturing process, quality control measures, and potential modifications. Modern plastic mold pricing reflects advancements in precision engineering, with costs varying based on cavity numbers, size specifications, and surface finish requirements. The pricing model considers both the immediate production needs and long-term durability, factoring in the mold's expected lifecycle and maintenance requirements. Contemporary plastic mold pricing also accounts for automated features, cooling systems, and specialized surface treatments that enhance production efficiency and product quality. Understanding plastic mold pricing is essential for manufacturers to optimize their investment while ensuring the production of high-quality plastic components that meet specific industry standards and customer requirements.