التشكيل بالحقن باثنين من الطلقات

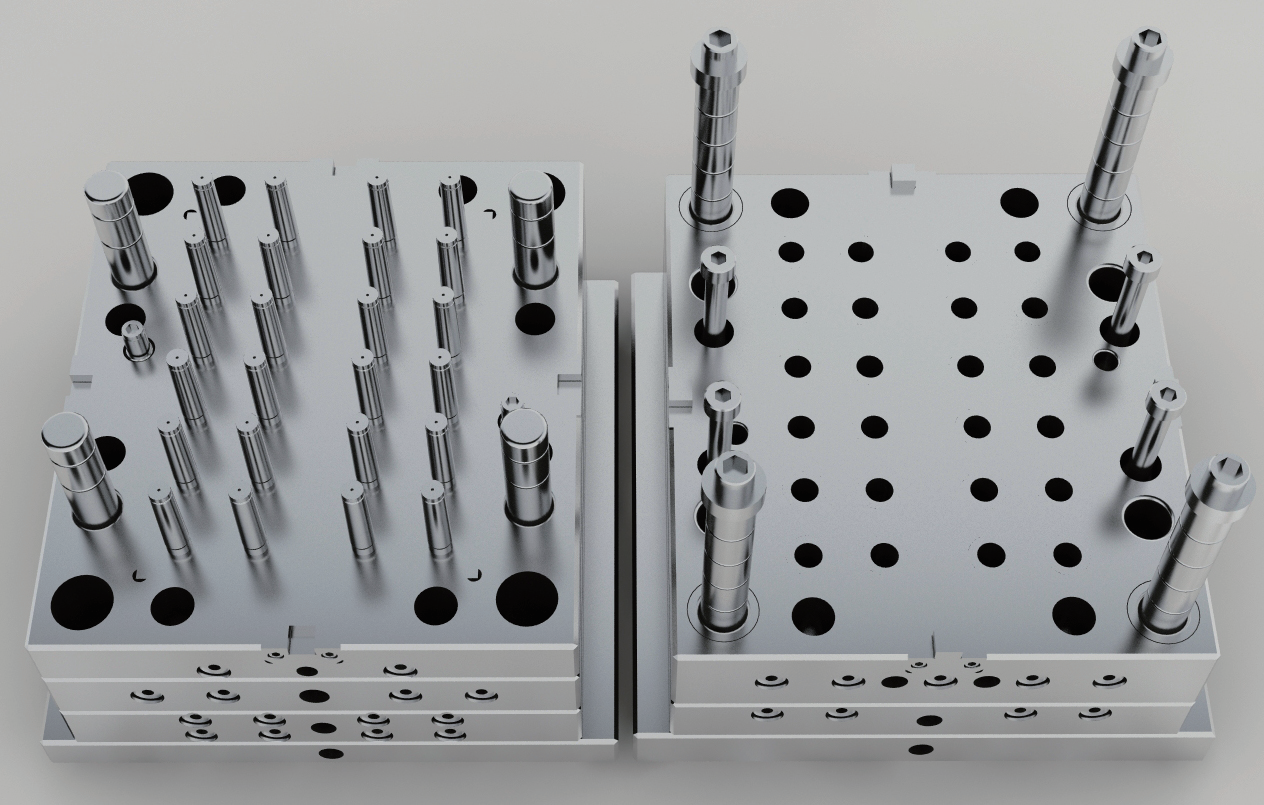

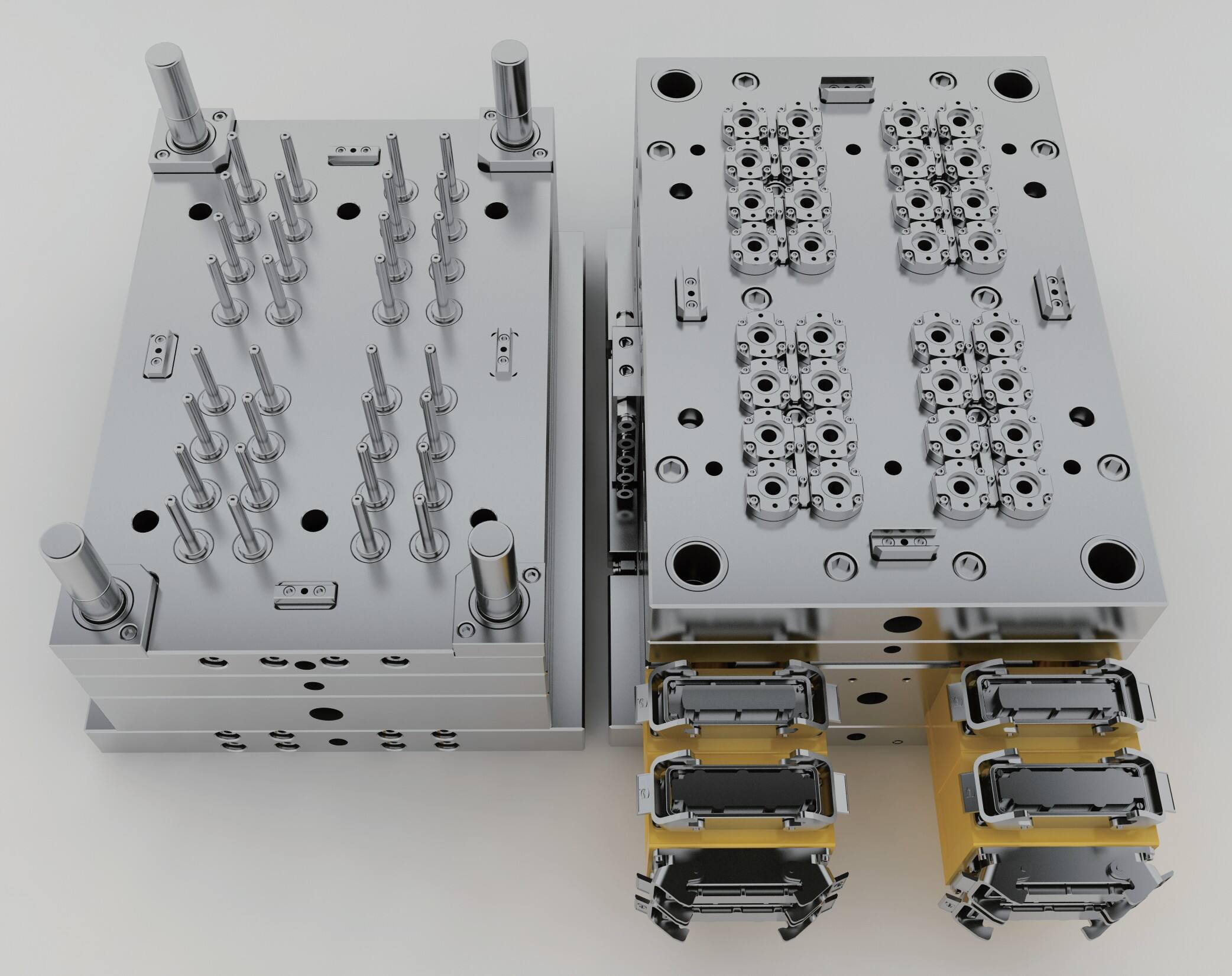

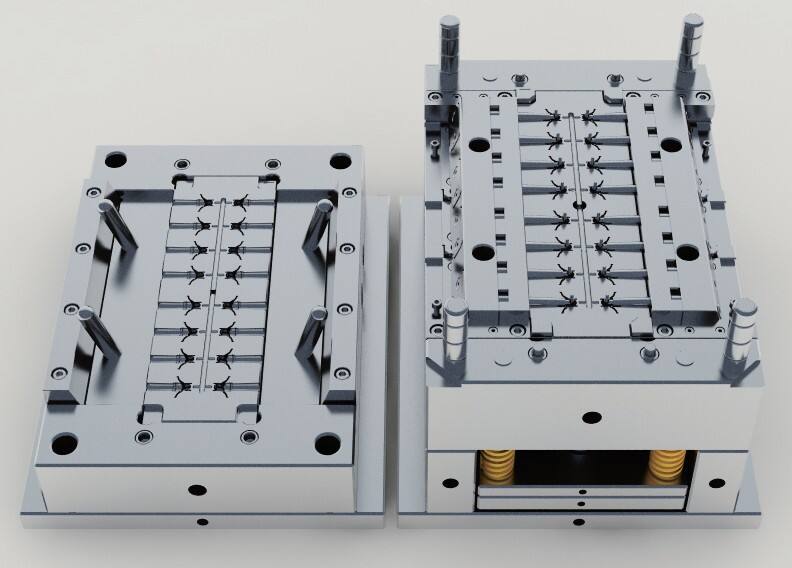

التشكيل بالحقن ثنائي الطلقة، والمعروف أيضًا بالتشكيل ثنائي الطلقة أو التشكيل متعدد المكونات، هو عملية تصنيع متقدمة تمكن من إنتاج قطع بلاستيكية معقدة باستخدام مادتين مختلفتين في عملية واحدة. هذه التقنية الابتكارية تسمح للصانعين بإنشاء مكونات ذات خواص وألوان ونسيج مختلف دون الحاجة إلى التجميع أو العمليات الثانوية. تتضمن العملية حقن مادتين مختلفتين بشكل متتالي في قالب مصمم خصيصًا، حيث يُنشئ الطلقة الأولى المكون الأساسي، ويضيف الطلقة الثانية الخصائص أو الميزات إلى مناطق محددة. لقد ثورة هذه التقنية تصميم المنتج وكفاءة التصنيع في مختلف الصناعات، بما في ذلك السيارات والإلكترونيات المستهلكين والأجهزة الطبية والأجهزة المنزلية. يمكن لهذه العملية دمج خصائص مواد مختلفة مثل البلاستيك الصلب والناعم أو إنشاء مجموعات ألوان مميزة داخل جزء واحد. يقدم التشكيل بالحقن ثنائي الطلقة تحكم دقيق في وضع المواد والتآزر، مما يضمن جودة مستمرة ويقلل من وقت الإنتاج مقارنة بالطرق التقليدية. تمكن هذه التقنية من إنشاء مقابض مريحة، وختم مضاد للماء، والعناصر الزخرفية والمكونات الوظيفية في دورة إنتاج واحدة وكفؤة.