3d printed injection mold

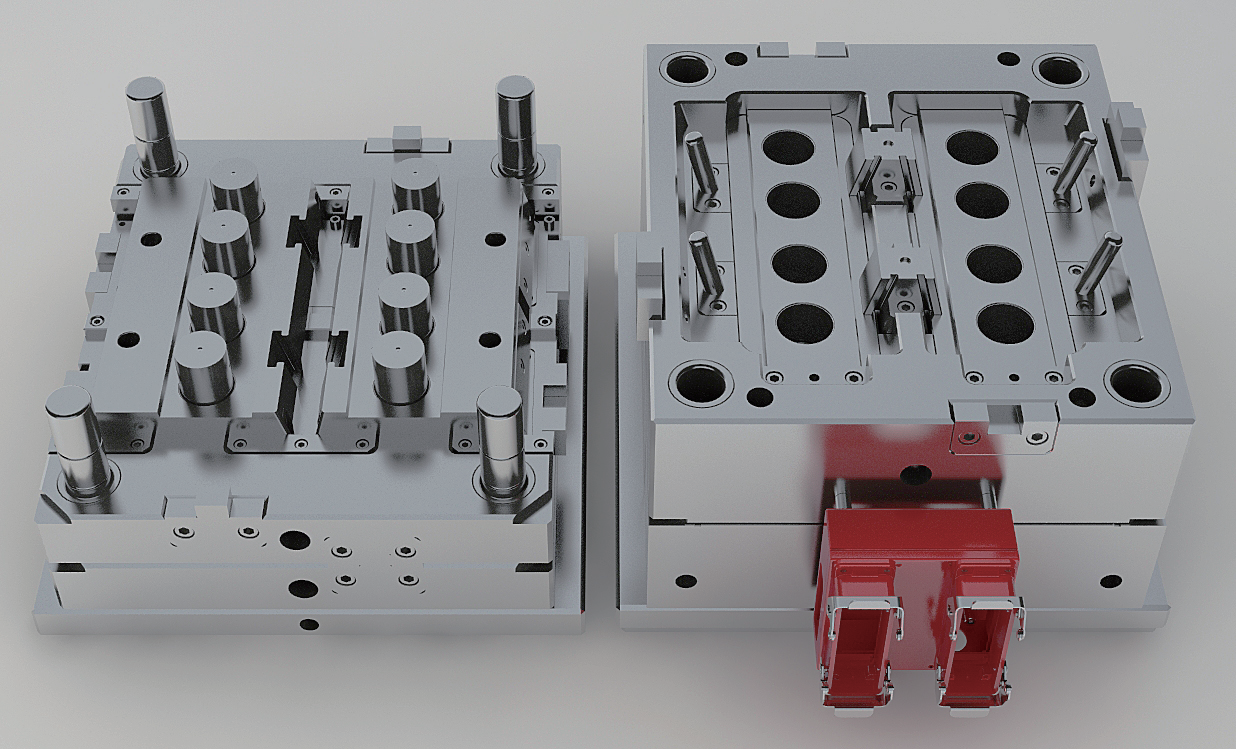

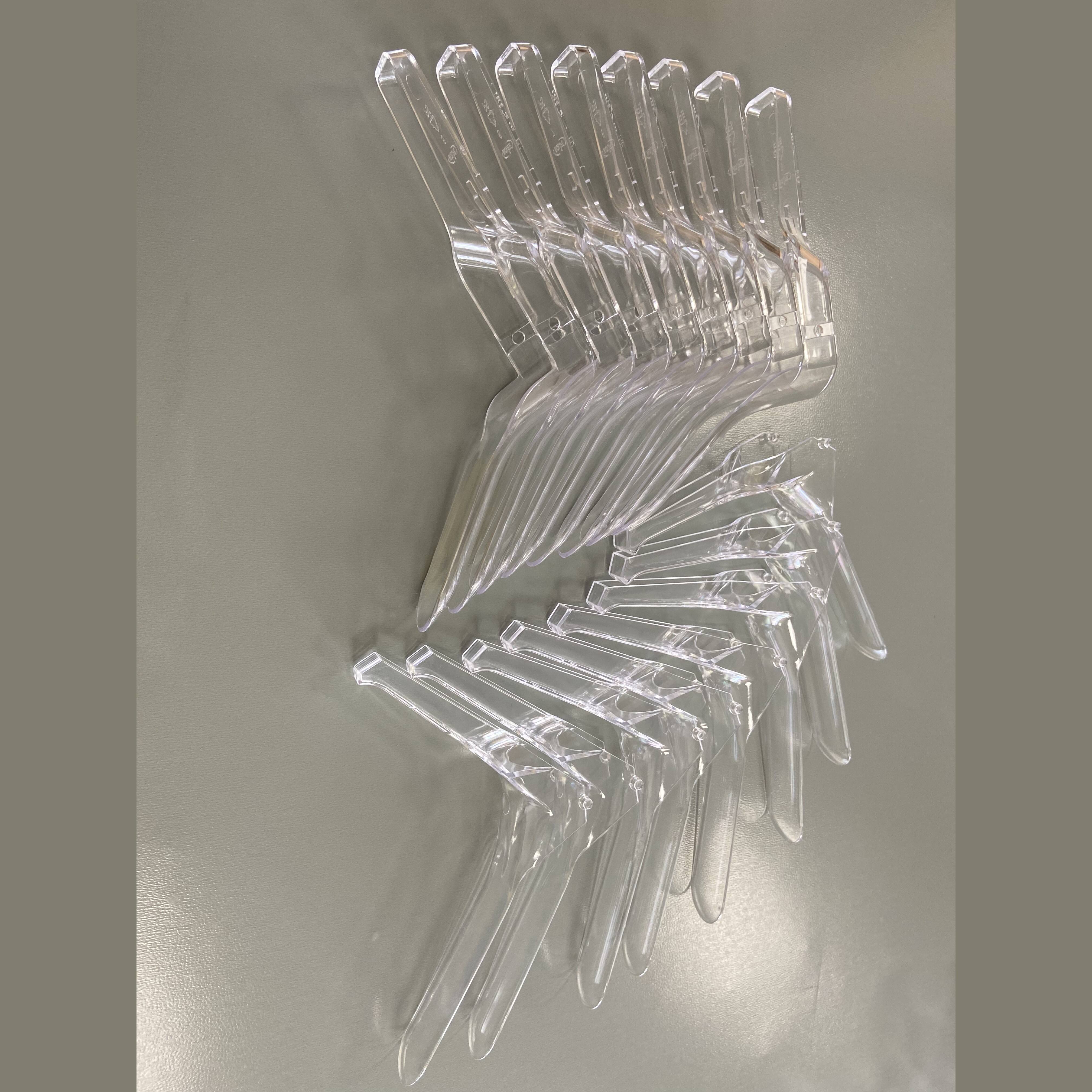

3D printed injection molds represent a revolutionary advancement in manufacturing technology, combining the flexibility of additive manufacturing with traditional injection molding processes. These innovative tools are created using high-performance 3D printing materials and advanced printing technologies to produce molds capable of manufacturing plastic parts. The process begins with a detailed CAD design, which is then translated into a physical mold through layer-by-layer 3D printing. These molds typically consist of two or more parts that fit together precisely, creating cavities that match the desired final product shape. The technology enables rapid prototyping and small-batch production, offering manufacturers the ability to produce complex geometries and intricate details that might be challenging with traditional molding methods. The molds can be designed with integrated cooling channels, optimized gate locations, and customized ejection systems, all of which contribute to improved part quality and production efficiency. While traditionally used for prototype and bridge tooling, technological advancements have made 3D printed injection molds increasingly suitable for low to medium volume production runs, particularly in industries such as automotive, consumer products, and medical devices.