insert moulding

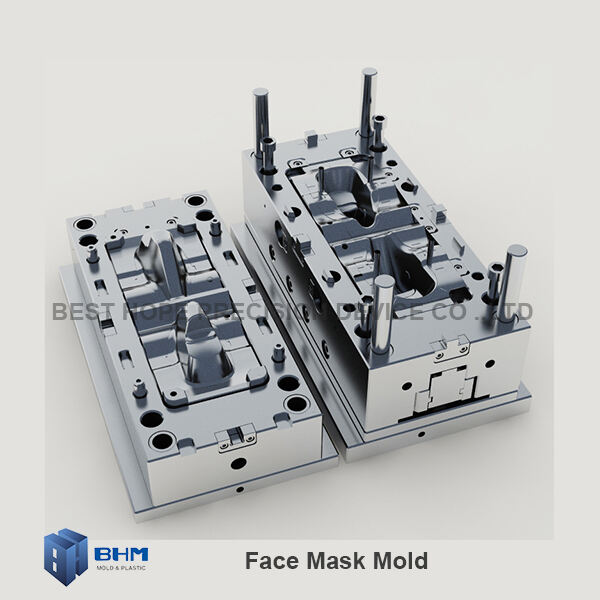

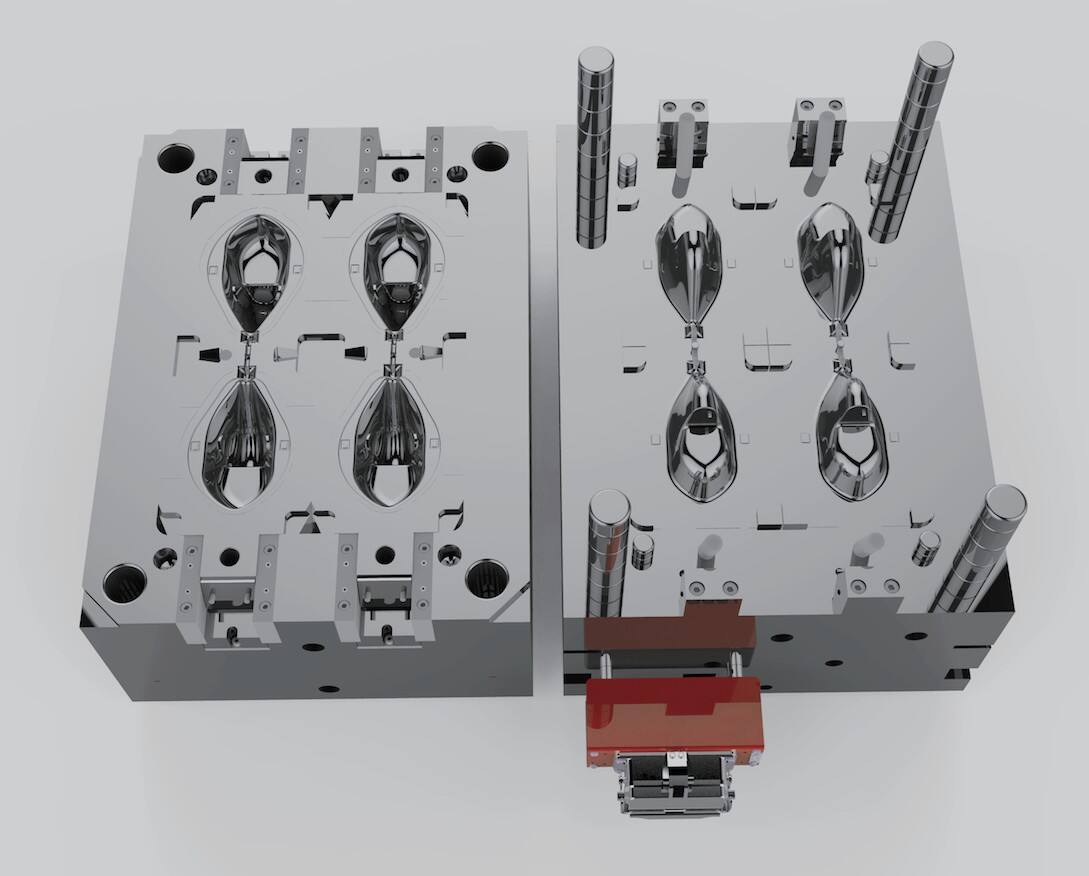

Insert moulding is an advanced manufacturing process that combines plastic injection moulding with the embedding of pre fabricated components, creating complex parts with enhanced functionality and durability. This innovative technique allows for the seamless integration of metal inserts, electronics, or other materials directly into plastic parts during the moulding process. The process begins with precisely placing inserts into the mould cavity before injecting molten plastic material, which then solidifies around these components, creating a strong mechanical bond. This technology is particularly valuable in industries requiring high strength connections, electrical conductivity, or thermal management. The process ensures superior component integration compared to traditional post moulding assembly methods, resulting in better structural integrity and reduced manufacturing steps. Insert moulding finds extensive applications in automotive components, electronic housings, medical devices, and consumer products, where it effectively combines the strength of metal with the versatility of plastics. The technology enables manufacturers to produce complex parts with precise tolerances while maintaining consistent quality across large production runs.