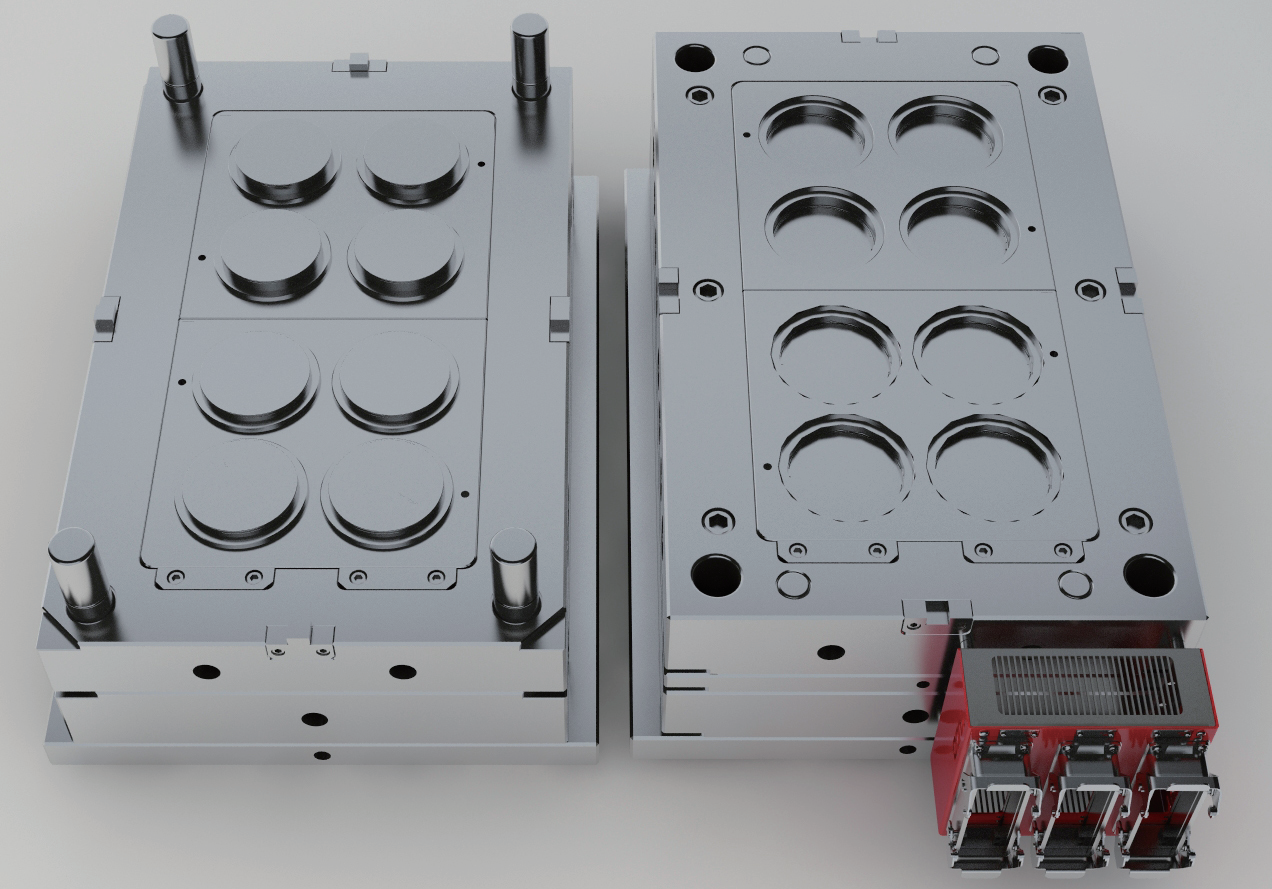

die injection

Die injection represents a sophisticated manufacturing process that has revolutionized the production of plastic components. This advanced technology involves injecting molten material into a mold cavity under high pressure, where it cools and solidifies into the desired shape. The process combines precision engineering with automated efficiency, utilizing specialized machinery that can produce complex parts with exceptional accuracy and consistency. The system comprises several key components, including the injection unit, which melts and conveys the material, the mold clamping unit that secures the die, and the control system that manages the entire operation. Modern die injection systems feature advanced temperature control mechanisms, precise pressure monitoring, and sophisticated automation capabilities that ensure optimal production conditions. The technology excels in producing both simple and intricate components, making it ideal for manufacturing everything from consumer goods to automotive parts and medical devices. The versatility of die injection allows for the use of various materials, including thermoplastics, thermosets, and metal alloys, each requiring specific processing parameters to achieve optimal results.