hdpe injection molding

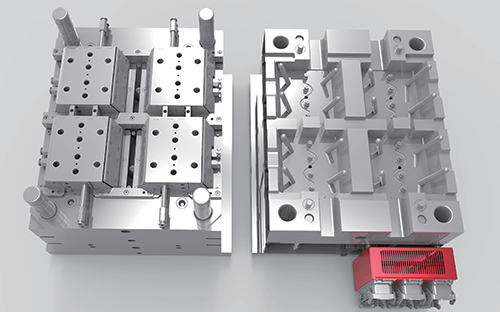

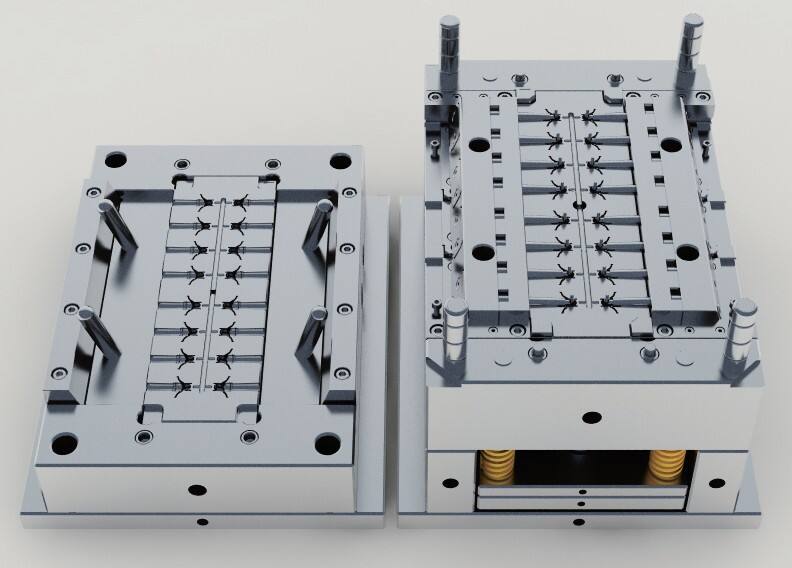

HDPE injection molding is a sophisticated manufacturing process that transforms high-density polyethylene into durable plastic products through precise temperature control and pressure application. This versatile method involves melting HDPE pellets and injecting the molten material into carefully designed molds under high pressure. The process stands out for its ability to produce complex geometries with exceptional consistency and quality. The technology incorporates advanced features such as computerized control systems, optimized cooling channels, and precise injection parameters to ensure optimal product quality. HDPE injection molding serves various industries, including automotive, consumer goods, packaging, and medical devices. The process excels in producing both small precision components and large-scale products while maintaining tight tolerances and structural integrity. Modern HDPE injection molding systems feature automated material handling, real-time monitoring capabilities, and energy-efficient operations. This manufacturing method allows for high-volume production runs while maintaining cost-effectiveness and minimal material waste. The versatility of HDPE as a material, combined with the precision of injection molding, enables manufacturers to create products with excellent chemical resistance, impact strength, and environmental durability.