injection manufacturing company

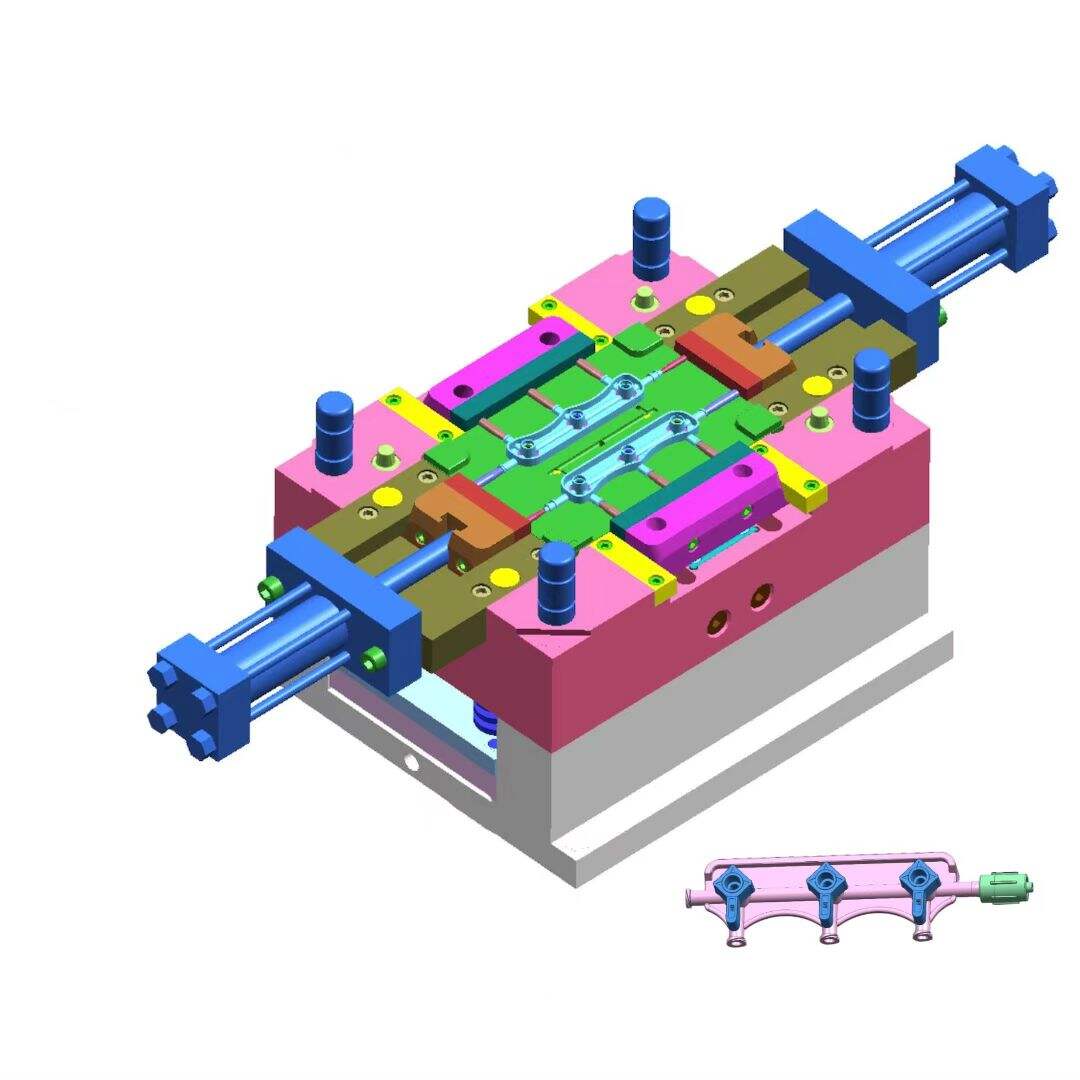

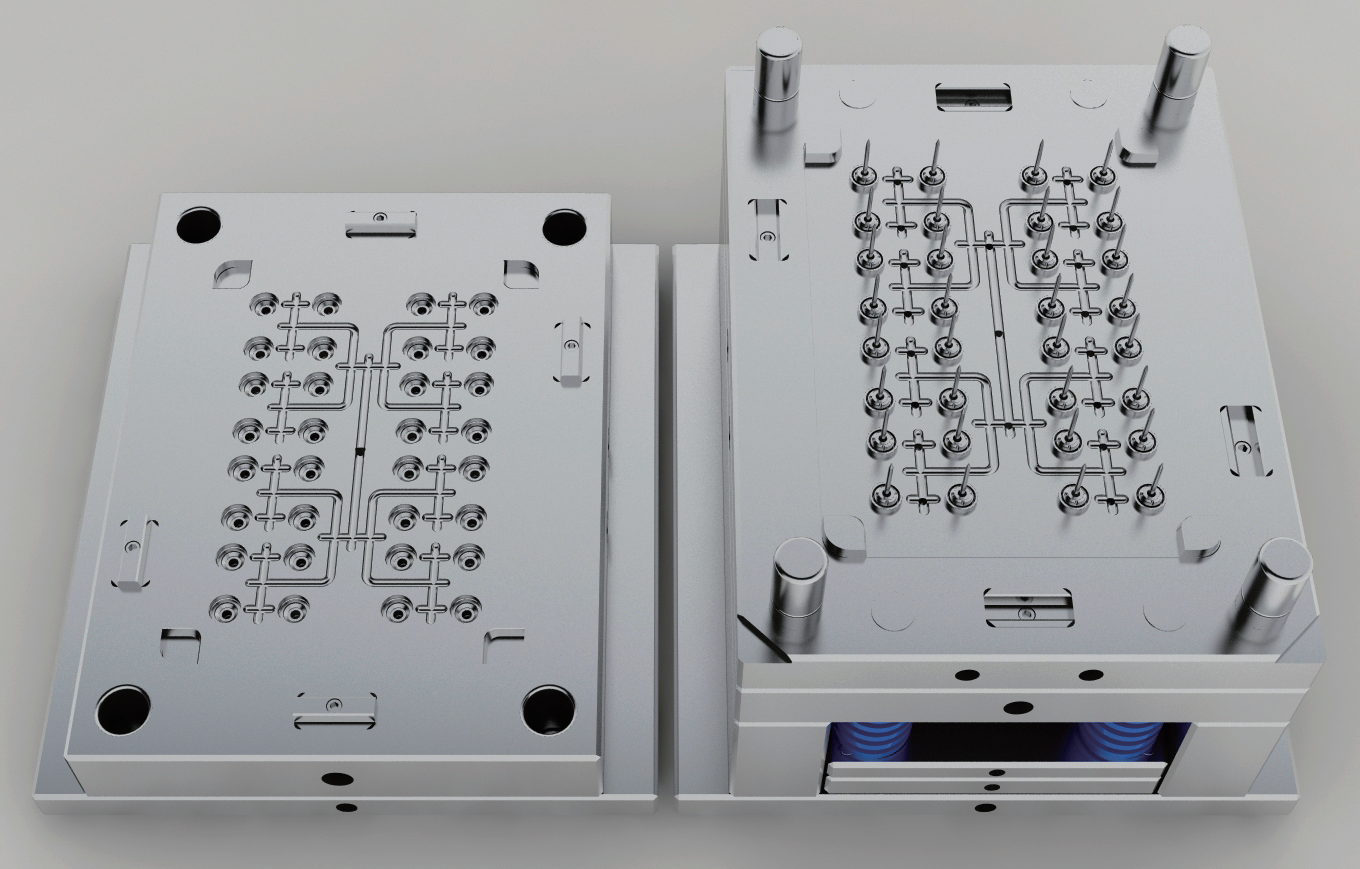

An injection manufacturing company represents a cutting-edge industrial facility specializing in precision plastic molding and advanced manufacturing solutions. With state-of-the-art machinery and automated systems, these facilities transform raw plastic materials into high-quality finished products through sophisticated injection molding processes. The company employs advanced computer-aided design (CAD) systems and robotics to ensure exceptional accuracy and consistency in production. Their capabilities extend across various sectors, including automotive, consumer electronics, medical devices, and industrial components. The facility maintains strict quality control measures, implementing real-time monitoring systems and automated inspection protocols to guarantee product integrity. The manufacturing process incorporates sustainable practices, utilizing energy-efficient equipment and recycling systems to minimize environmental impact. Their technical expertise covers a wide range of materials, from standard thermoplastics to high-performance engineering polymers, enabling them to serve diverse industry requirements. The facility operates with multiple injection molding machines of varying capacities, allowing for flexible production volumes and customization options. They also provide comprehensive support services, including product design optimization, prototype development, and post-production finishing.