injection molding production

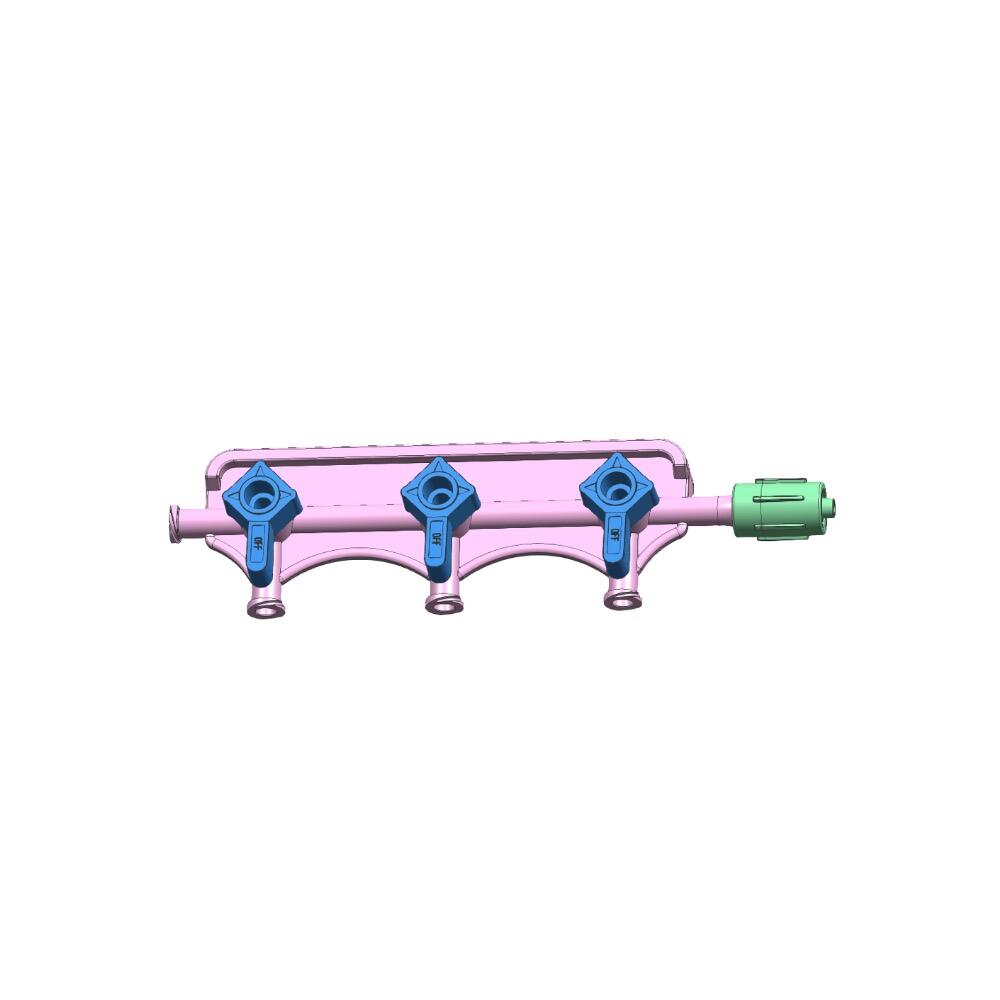

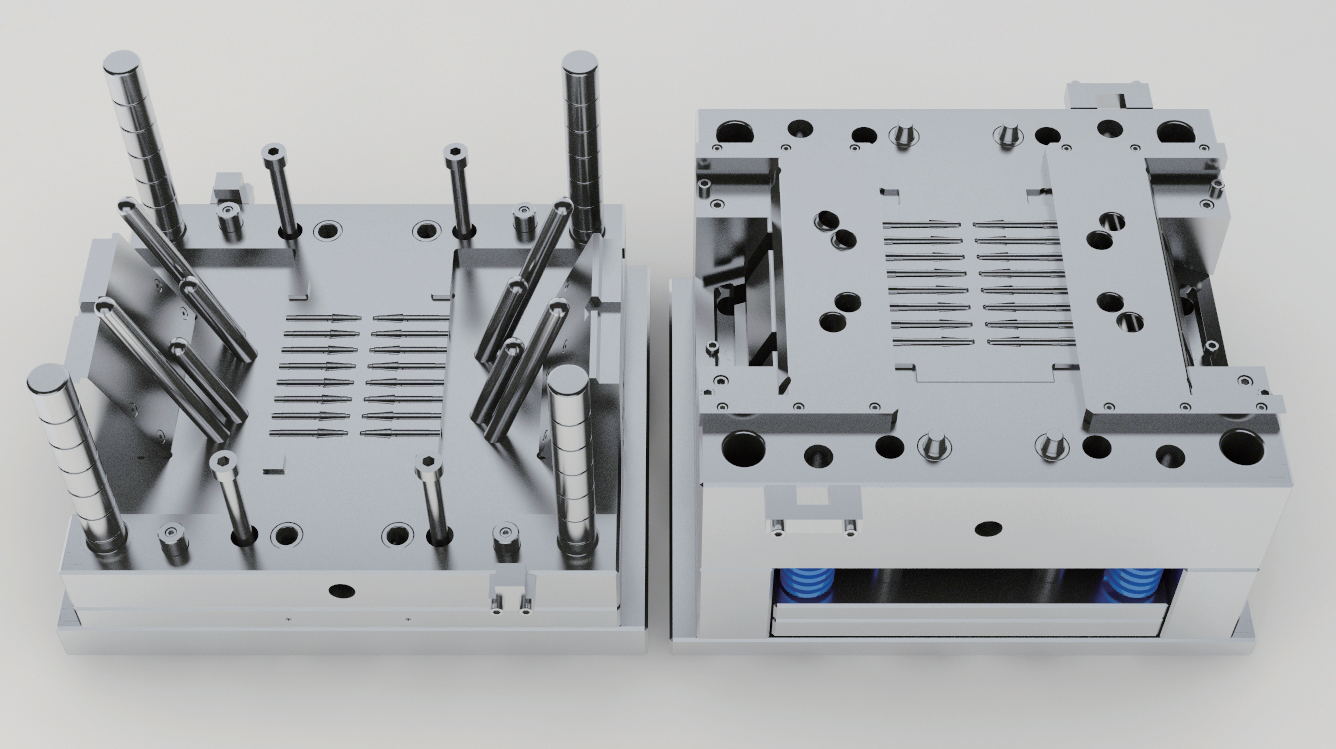

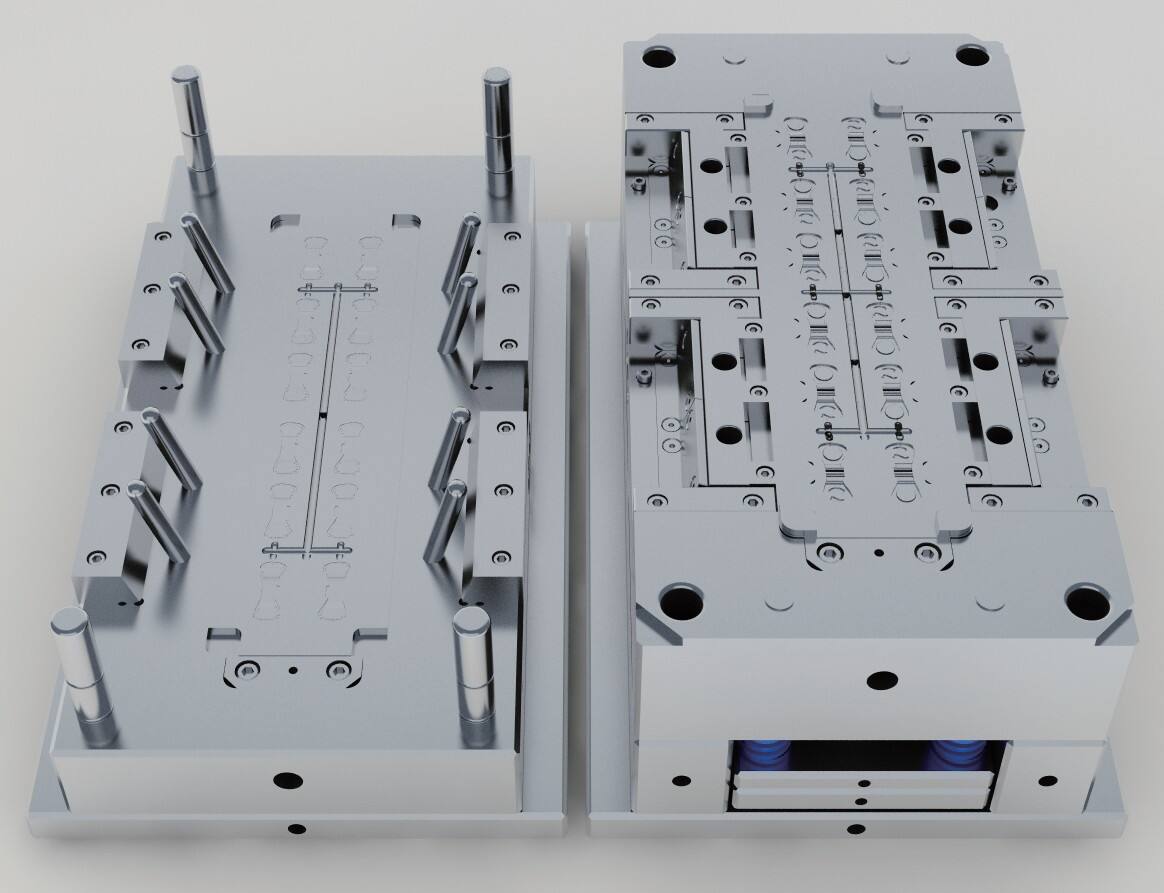

Injection molding production represents a revolutionary manufacturing process that transforms plastic materials into precisely engineered products through a sophisticated combination of heat, pressure, and cooling. This versatile technology involves injecting molten plastic material into custom-designed molds, where it solidifies to create components with exceptional accuracy and consistency. The process begins with plastic pellets being fed into a heated barrel, where they melt into a uniform liquid state. This molten plastic is then forcefully injected into a precisely engineered mold cavity under high pressure. The material rapidly cools and solidifies, taking the exact shape of the mold. Advanced temperature control systems and precise timing mechanisms ensure optimal product quality throughout the production cycle. Modern injection molding machines incorporate sophisticated automation features, digital controls, and real-time monitoring capabilities, enabling manufacturers to maintain strict quality standards while achieving high production volumes. This technology serves diverse industries, including automotive, consumer electronics, medical devices, and household products, offering unparalleled flexibility in producing components of various sizes, complexities, and material compositions.