liquid silicone molding

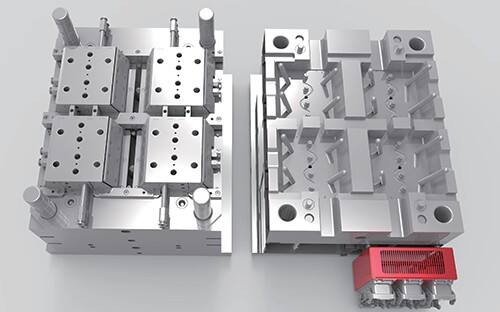

Liquid silicone molding is an advanced manufacturing process that transforms liquid silicone rubber (LSR) into precise, high-quality components through injection molding technology. This innovative process begins with two liquid components that, when mixed and heated, create a solid elastomeric material with exceptional properties. The technology utilizes specialized equipment that precisely controls temperature, pressure, and material flow to produce consistent, high-quality parts. The process stands out for its ability to create complex geometries with excellent detail reproduction and dimensional stability. What makes liquid silicone molding particularly valuable is its capacity to produce parts with superior heat resistance, chemical inertness, and biocompatibility. The technology is automated and highly efficient, allowing for high-volume production while maintaining consistent quality. This manufacturing method is particularly well-suited for medical devices, automotive components, consumer goods, and electronics, where precision and material purity are crucial. The process also offers excellent flexibility in design, allowing for the creation of both simple and intricate parts with varying wall thicknesses and complex features.