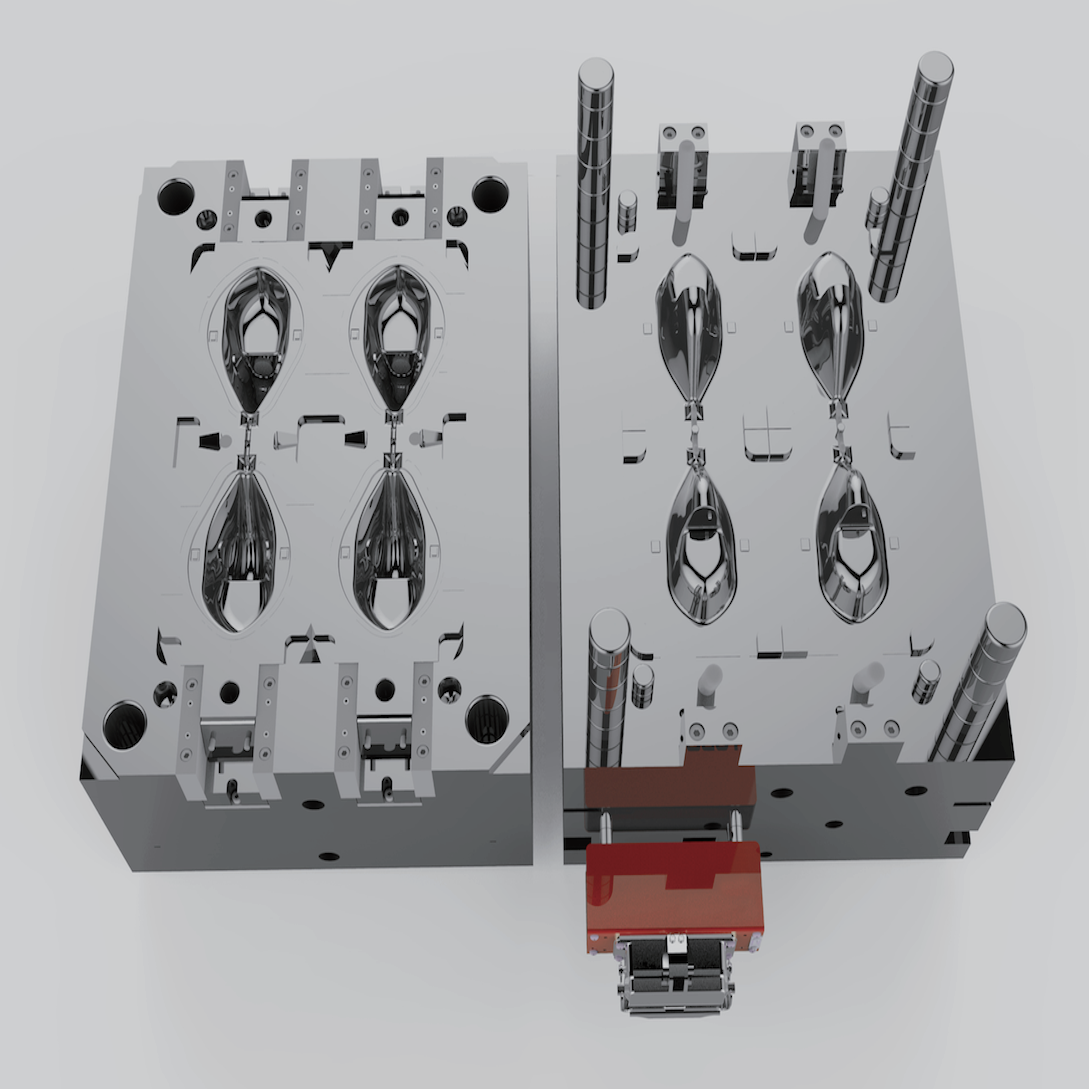

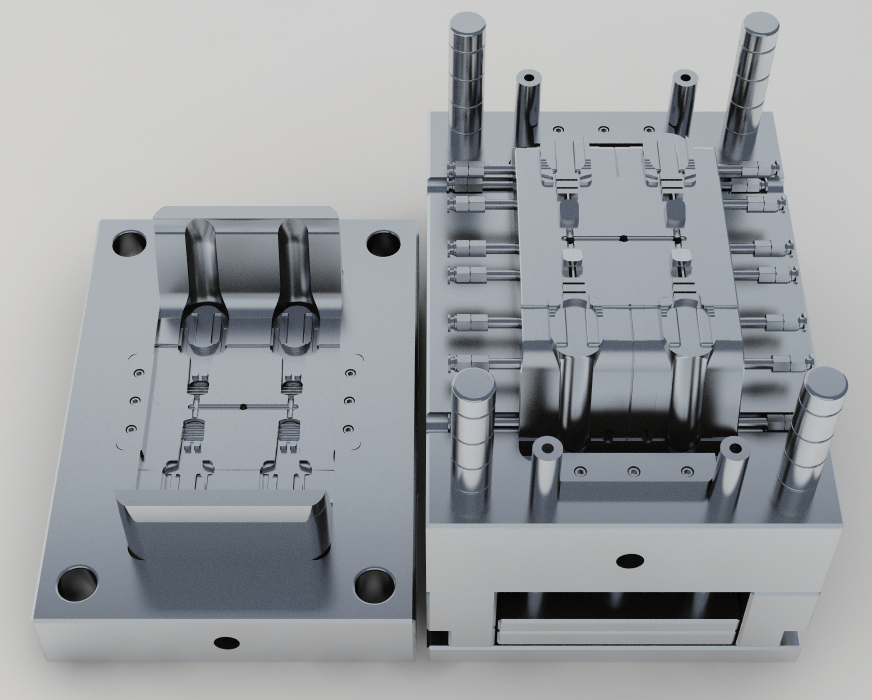

injection molding products

Injection molding products represent a cornerstone of modern manufacturing, offering unprecedented precision and versatility in producing complex plastic components. This manufacturing process involves injecting molten plastic material into a precisely engineered mold cavity, where it cools and solidifies into the desired shape. The technology encompasses a wide range of capabilities, from producing microscopic medical components to large automotive parts. Advanced injection molding systems incorporate sophisticated controls for temperature, pressure, and timing, ensuring consistent quality across production runs. These products feature exceptional surface finishes, tight tolerances, and the ability to integrate multiple materials in a single component. The application spectrum spans across numerous industries, including automotive, medical, consumer electronics, and household goods. Modern injection molding products utilize smart manufacturing principles, incorporating sensors and automated quality control systems to maintain production efficiency and reduce waste. The technology also supports sustainable manufacturing practices through material optimization and recycling capabilities, making it an environmentally conscious choice for mass production.