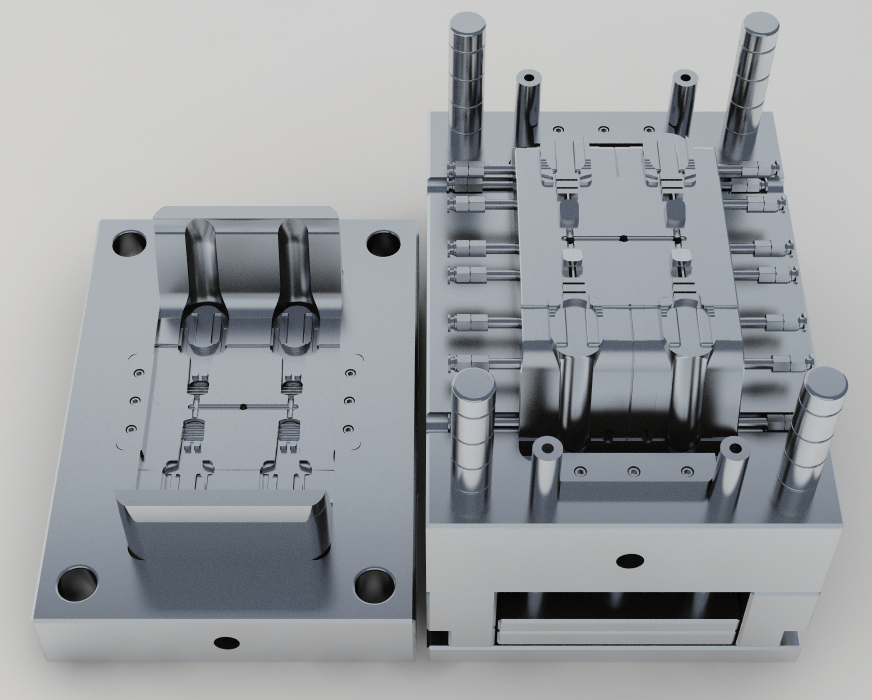

3d printed molds for injection molding

3D printed molds for injection molding represent a groundbreaking advancement in manufacturing technology, combining the flexibility of additive manufacturing with traditional injection molding processes. These molds are created using high-performance 3D printing technologies, enabling rapid prototyping and small-batch production runs with significantly reduced lead times. The process involves designing the mold digitally, printing it using specialized materials that can withstand injection molding temperatures and pressures, and then using these molds in standard injection molding machines. The technology accommodates complex geometries and intricate details that might be challenging or impossible to achieve with traditional mold making methods. These molds are particularly valuable in industries such as automotive, consumer products, and medical devices, where quick iterations and customization are essential. The materials used for printing these molds include high-temperature resins, reinforced polymers, and metal composites, each selected based on the specific requirements of the end product. The technology allows for integrated cooling channels, optimized gate locations, and other functional features that can be seamlessly incorporated into the mold design, improving the overall injection molding process.