custom injection molding companies

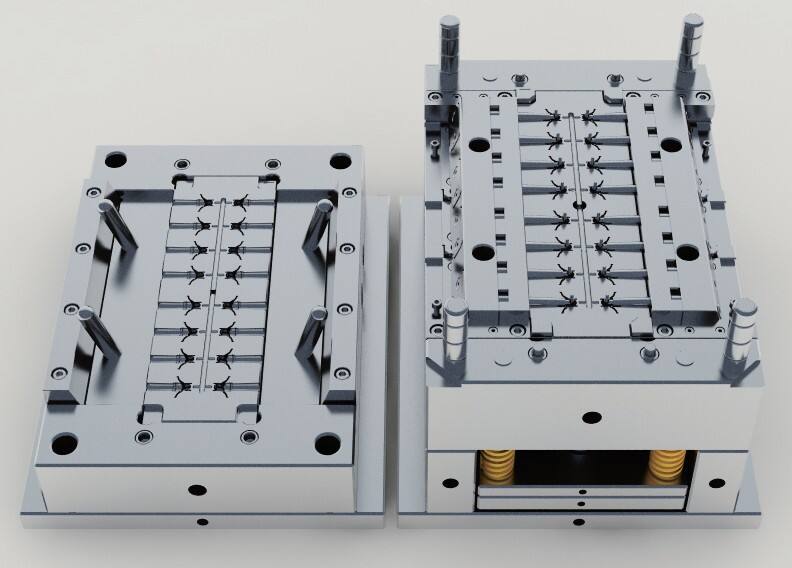

Custom injection molding companies are specialized manufacturing facilities that provide comprehensive solutions for producing plastic parts and components according to specific client requirements. These companies utilize advanced injection molding technology to transform plastic resins into precise, high-quality products through a carefully controlled process of heating, injecting, and cooling materials in custom-designed molds. They employ state-of-the-art equipment and sophisticated software for design optimization, mold flow analysis, and quality control. These facilities typically offer end-to-end services, from initial product design and prototyping to full-scale production and assembly. Their capabilities extend to working with a wide range of thermoplastic and thermosetting materials, accommodating various part sizes, complexities, and production volumes. Custom injection molding companies integrate modern automation systems and quality control measures to ensure consistent product quality and efficient production cycles. They serve diverse industries including automotive, medical, consumer goods, electronics, and aerospace, providing solutions for both simple components and complex assemblies. These companies often maintain certified clean room facilities for medical and electronic components, and implement strict quality management systems to meet international standards and industry-specific requirements.