clean room injection molding

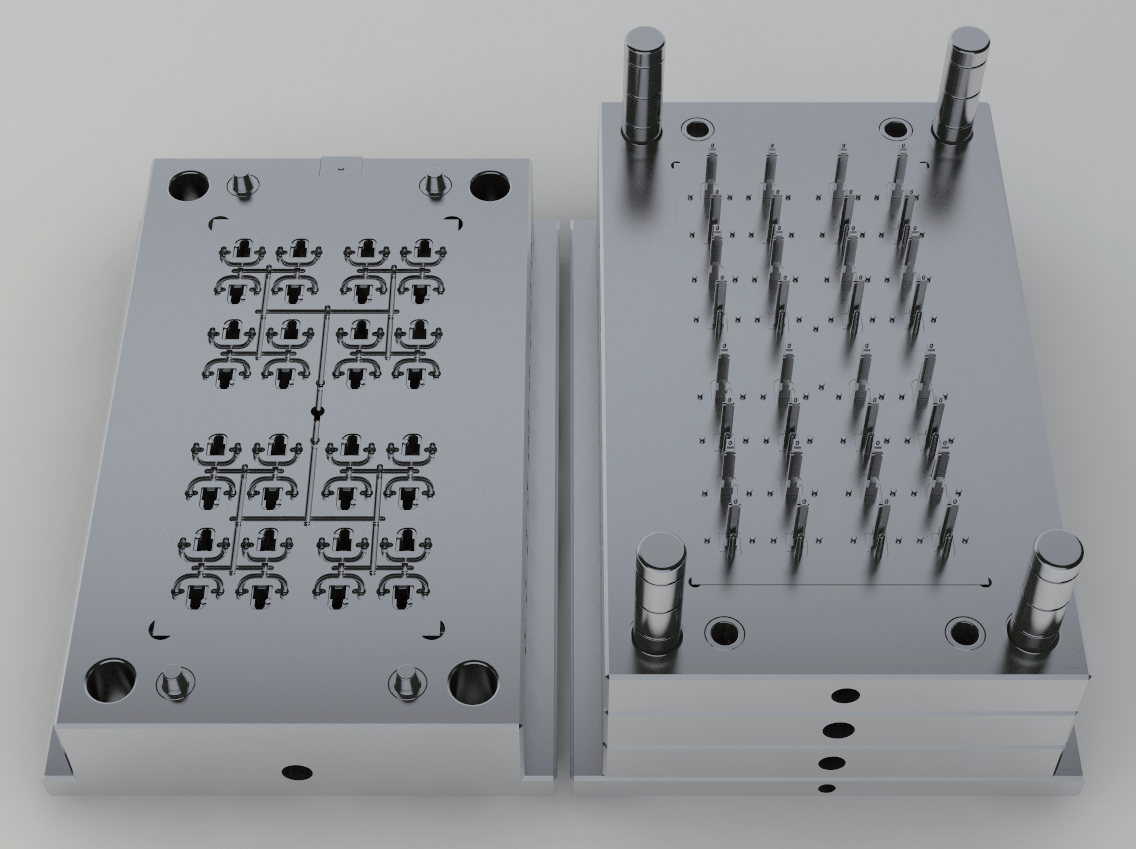

Clean room injection molding is a specialized manufacturing process that combines traditional injection molding techniques with controlled environmental conditions to produce contamination-free plastic components. This advanced manufacturing method takes place in a strictly regulated clean room environment where air quality, temperature, humidity, and particulate levels are carefully monitored and maintained. The process involves injecting molten plastic material into precisely engineered molds under sterile conditions, ensuring the final products meet stringent cleanliness requirements. The technology is particularly crucial in manufacturing medical devices, pharmaceutical packaging, and sensitive electronic components where even microscopic contamination could compromise product integrity. The clean room environment is classified according to ISO standards, with different levels of cleanliness available depending on the specific requirements of the end product. Advanced filtration systems, positive air pressure, and specialized equipment work together to maintain the pristine manufacturing environment. Operators wear appropriate protective gear and follow strict protocols to prevent contamination. This process enables the production of high-precision components with exceptional cleanliness levels, making it indispensable for industries where product purity is paramount.