medical mold design company

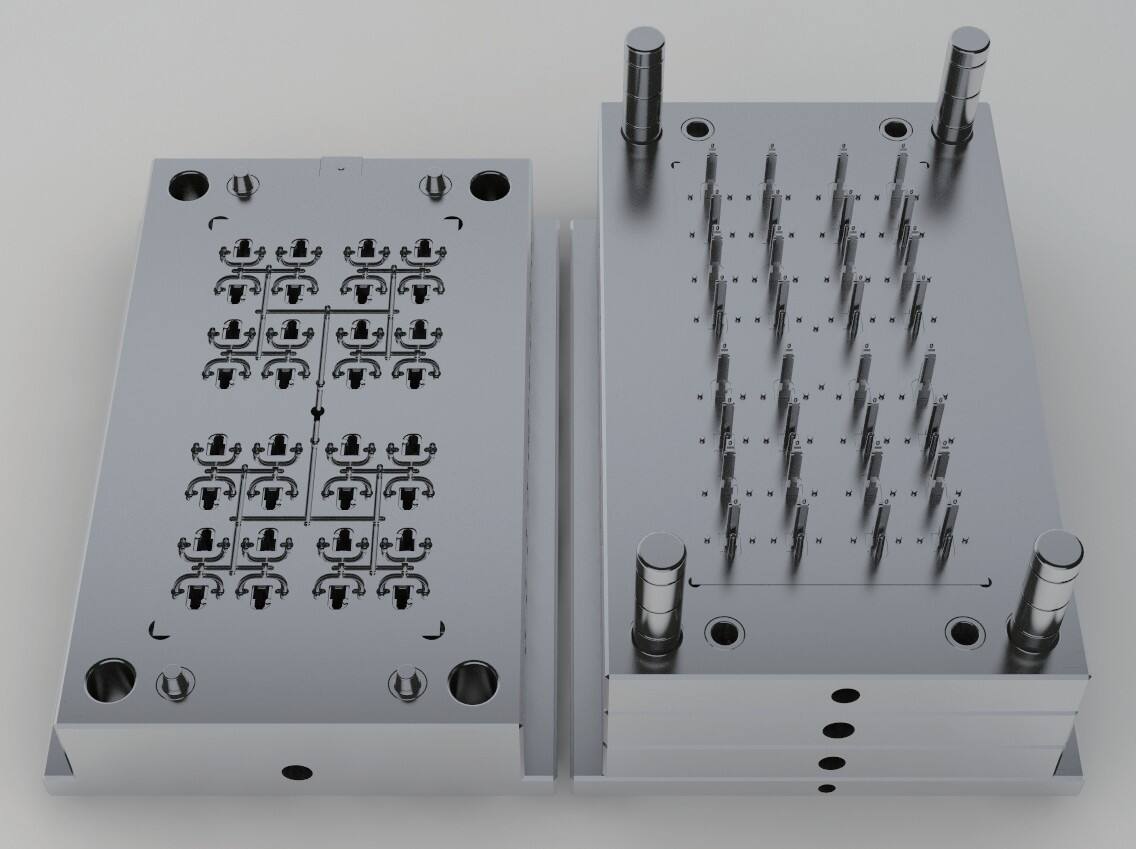

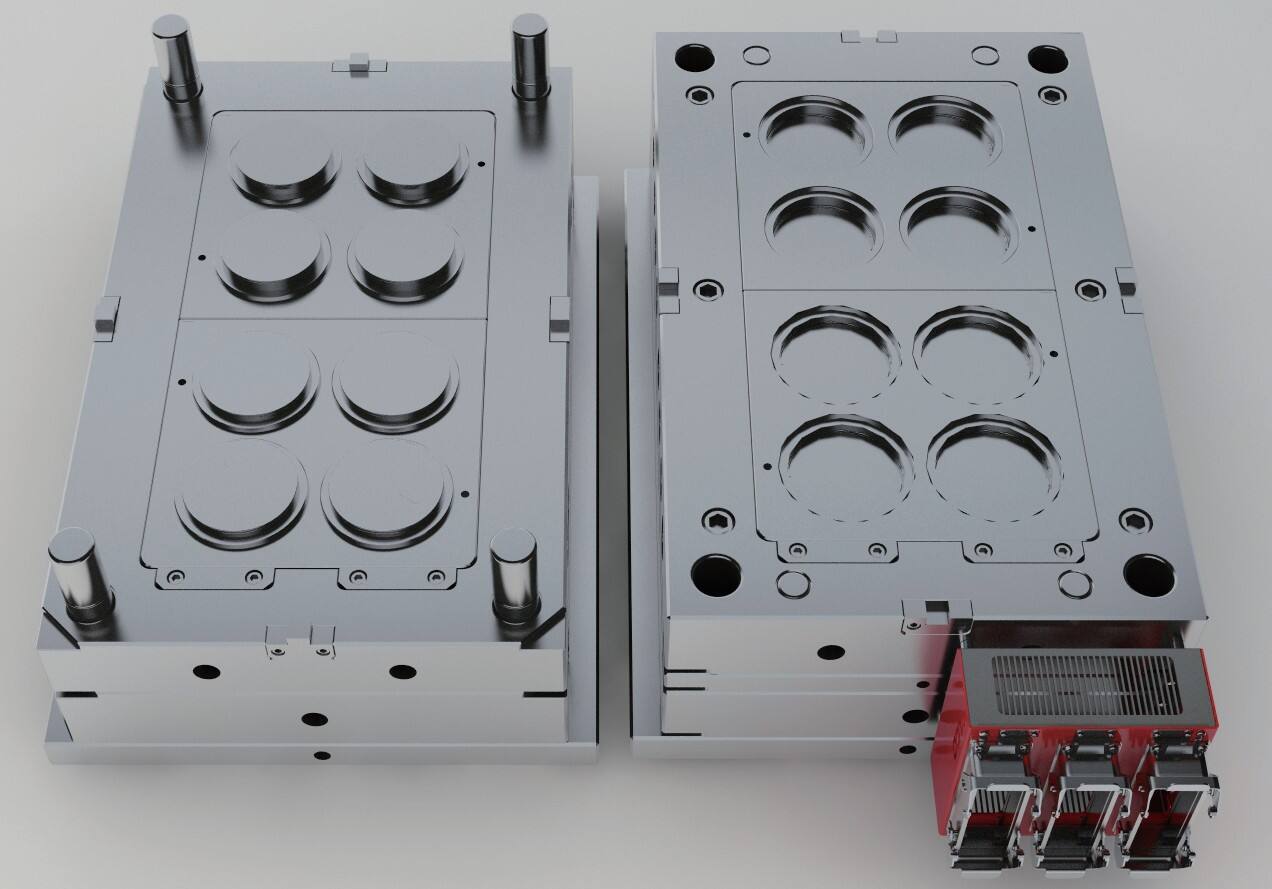

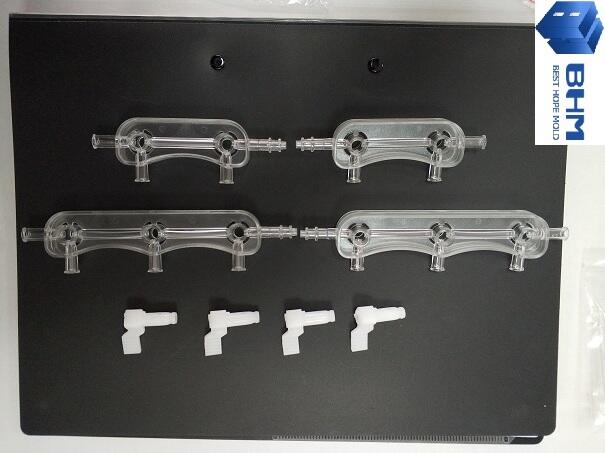

A medical mold design company stands at the forefront of healthcare innovation, specializing in the creation of precision molds for medical devices and components. With state-of-the-art CAD/CAM technology and advanced manufacturing capabilities, these companies develop custom solutions for medical equipment manufacturers worldwide. Their expertise encompasses the design and production of molds for various medical applications, including surgical instruments, diagnostic devices, and pharmaceutical packaging. The company's engineering team utilizes cutting-edge simulation software to optimize mold designs, ensuring optimal material flow and product quality. They maintain strict adherence to ISO 13485 medical standards and FDA regulations, guaranteeing the highest level of quality and safety in medical device manufacturing. The facility features clean room environments for sensitive medical component production, equipped with advanced injection molding machines and quality control systems. Their comprehensive services include prototype development, design validation, and full-scale production support, making them a one-stop solution for medical manufacturing needs.