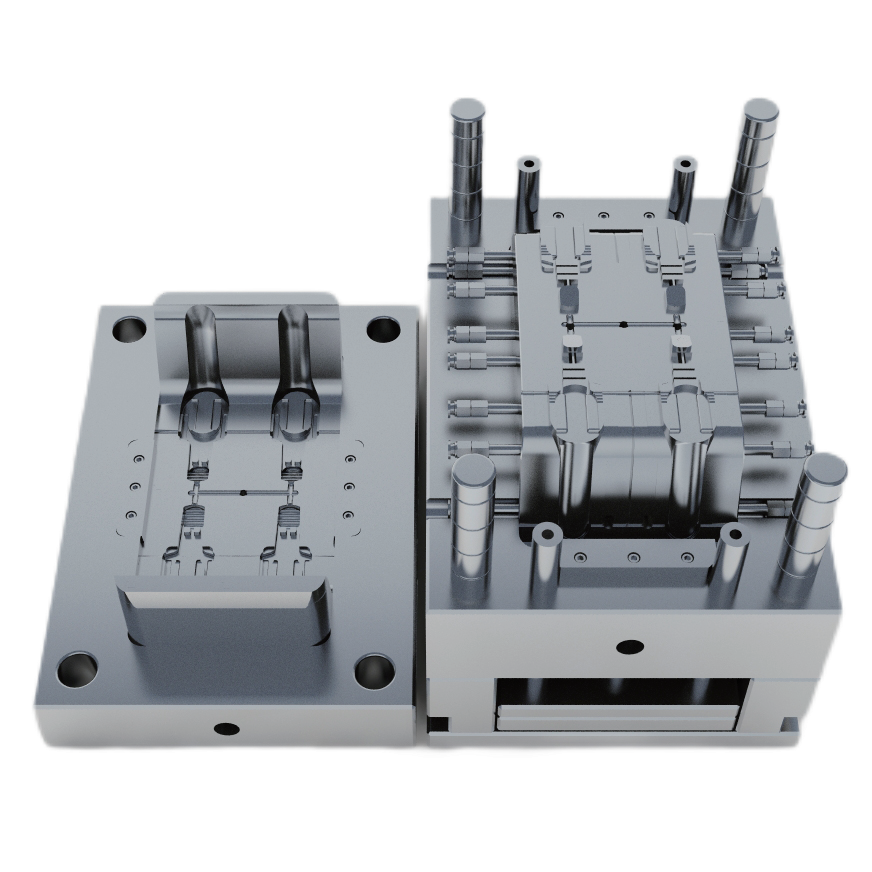

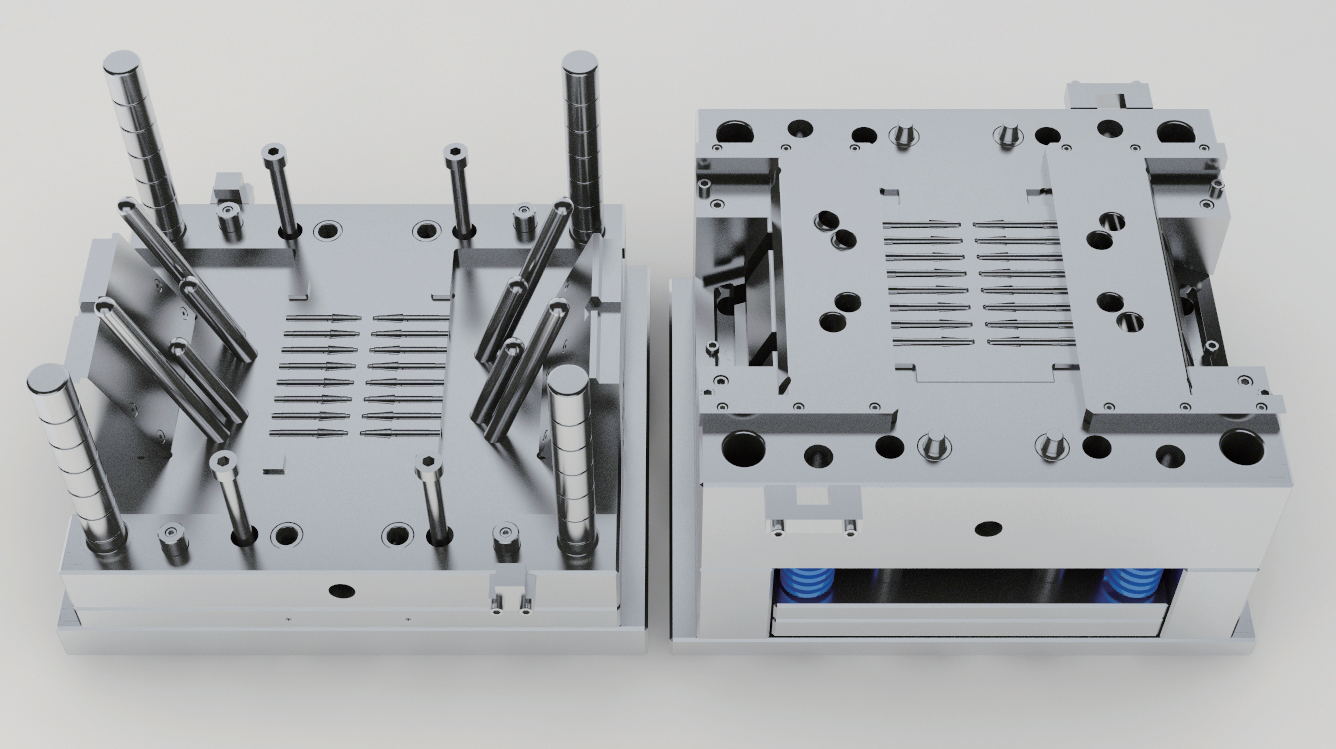

medical mold processing

Medical mold processing represents a crucial aspect of modern healthcare manufacturing, combining precision engineering with advanced materials science. This specialized manufacturing process involves creating highly accurate molds for medical devices, components, and equipment that meet stringent industry standards. The process encompasses multiple stages, including design optimization, material selection, precision machining, and quality control verification. Advanced CNC machinery and computer-aided manufacturing systems ensure exceptional accuracy down to microscopic levels, essential for producing medical components that must meet exact specifications. The technology enables the production of complex geometries and intricate details required for various medical applications, from surgical instruments to diagnostic equipment components. Medical mold processing incorporates state-of-the-art clean room facilities and specialized materials that comply with medical-grade requirements, ensuring biocompatibility and sterilization capabilities. The process also integrates sophisticated quality control measures, including real-time monitoring systems and automated inspection protocols, to maintain consistent production standards and regulatory compliance. This manufacturing approach serves various medical sectors, including pharmaceutical packaging, diagnostic equipment, surgical tools, and implantable medical devices, making it an indispensable part of the medical manufacturing industry.