medical mold design

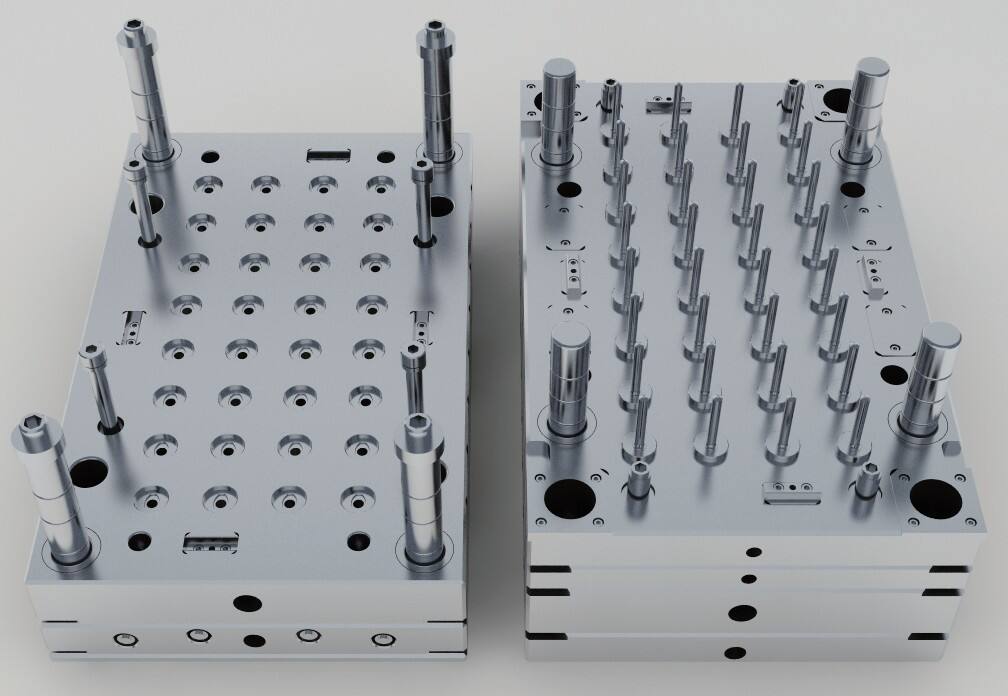

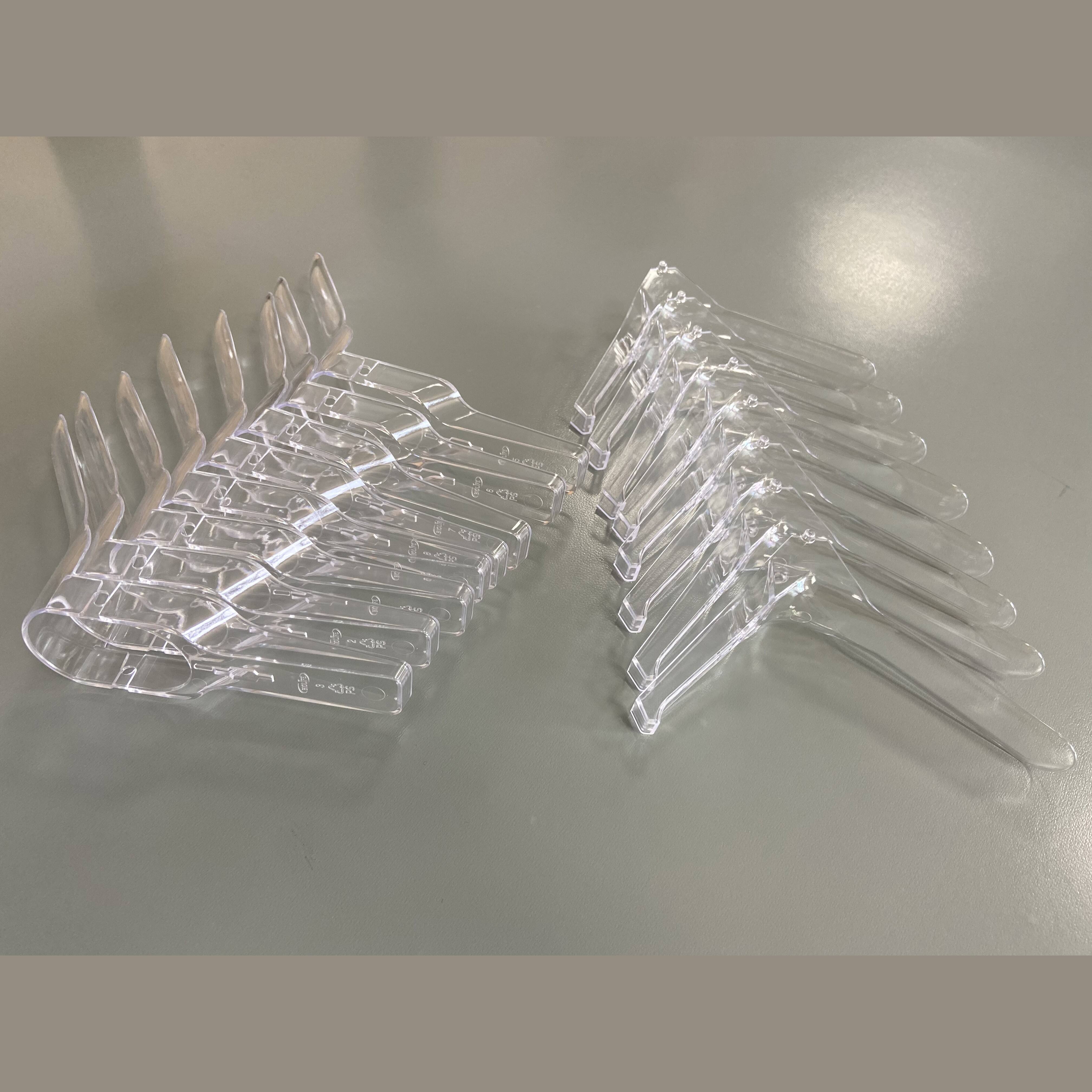

Medical mold design represents a critical component in the healthcare manufacturing industry, encompassing the precise engineering and development of tools used to produce medical devices and components. This sophisticated process combines advanced CAD/CAM technology with stringent quality control measures to ensure the production of high precision medical parts. The design process incorporates specific considerations for biocompatibility, sterilization requirements, and regulatory compliance while maintaining exceptional dimensional accuracy. Modern medical mold design utilizes advanced simulation software to optimize material flow, minimize defects, and ensure consistent production quality. These molds are engineered to handle specialized medical grade materials, including various thermoplastics and silicone compounds, while maintaining strict tolerances essential for medical applications. The design process also accounts for clean room manufacturing conditions, incorporating features that minimize particulate generation and facilitate easy cleaning and maintenance. Medical molds often include advanced features such as hot runner systems, precise temperature control mechanisms, and specialized venting solutions to ensure the production of defect free medical components.