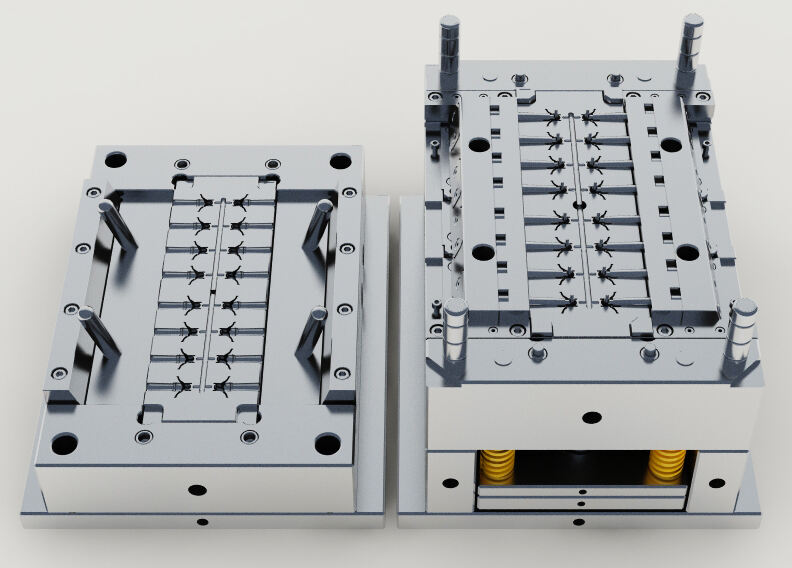

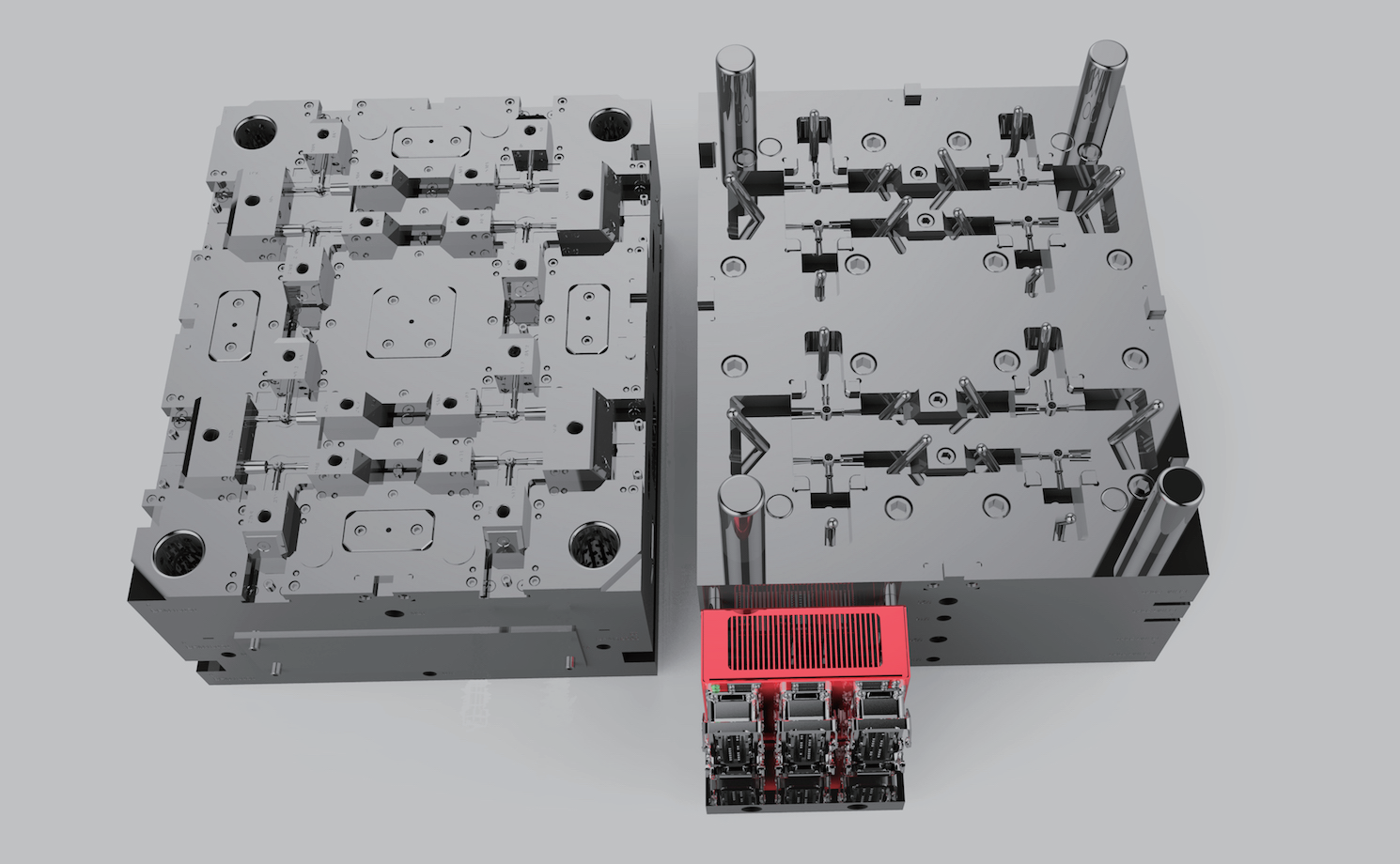

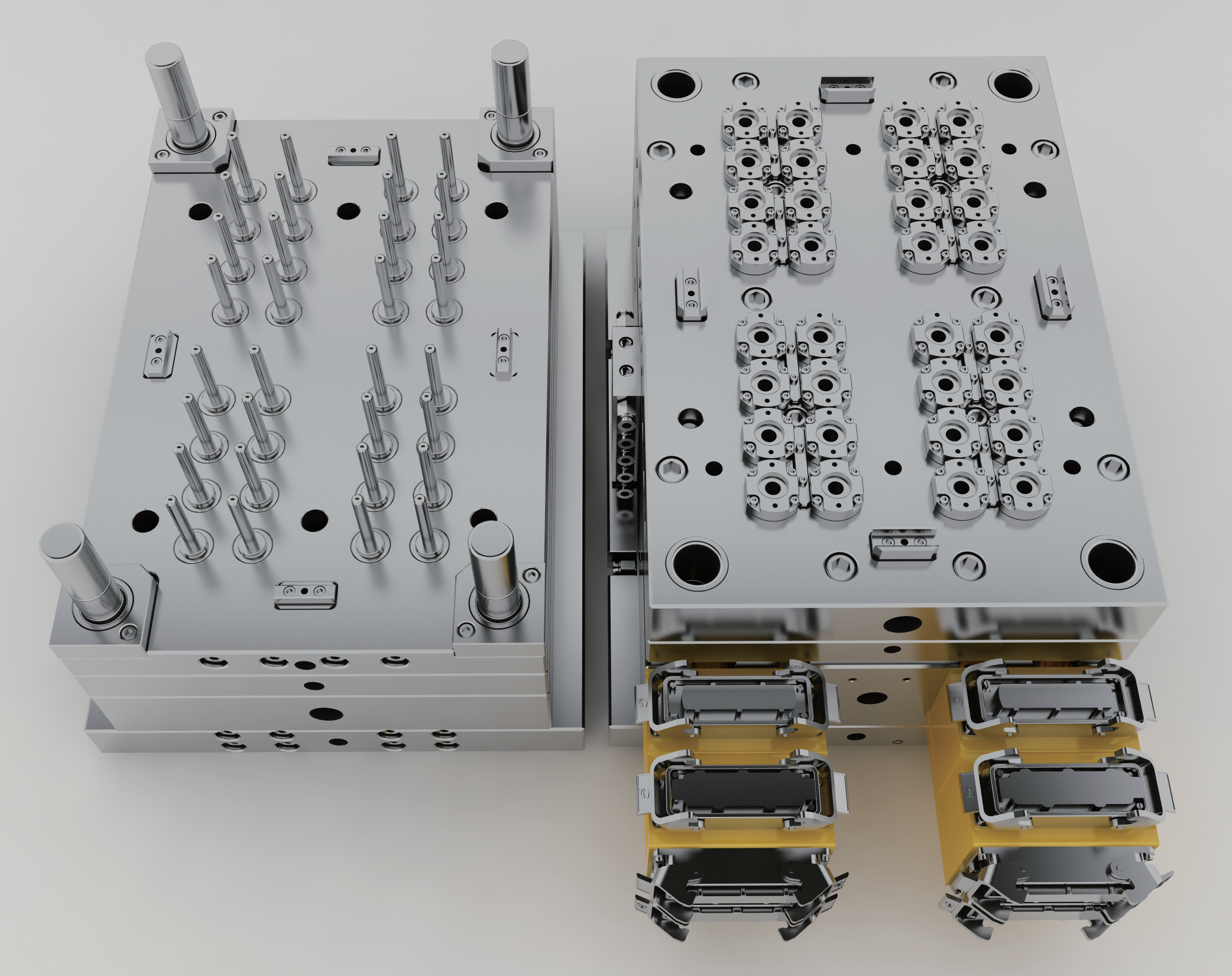

mold tooling

Mold tooling represents a critical component in modern manufacturing, serving as the foundation for precise and efficient production processes. This sophisticated technology encompasses the design, creation, and maintenance of molds used in various manufacturing applications, particularly in plastic injection molding and metal forming. The tooling system consists of multiple precisely engineered components, including the mold base, cavity and core inserts, cooling channels, and ejection mechanisms. These elements work in harmony to ensure consistent product quality and optimal production efficiency. Advanced mold tooling incorporates cutting-edge features such as conformal cooling systems, which provide uniform temperature control throughout the molding process, and sophisticated venting systems that prevent defects caused by trapped air. The technology also embraces modern innovations like hot runner systems for improved material flow and reduced waste, alongside sophisticated surface treatments that enhance mold durability and performance. In contemporary manufacturing, mold tooling plays a pivotal role in industries ranging from automotive and aerospace to consumer goods and medical devices, enabling the production of complex geometries with tight tolerances and superior surface finishes.