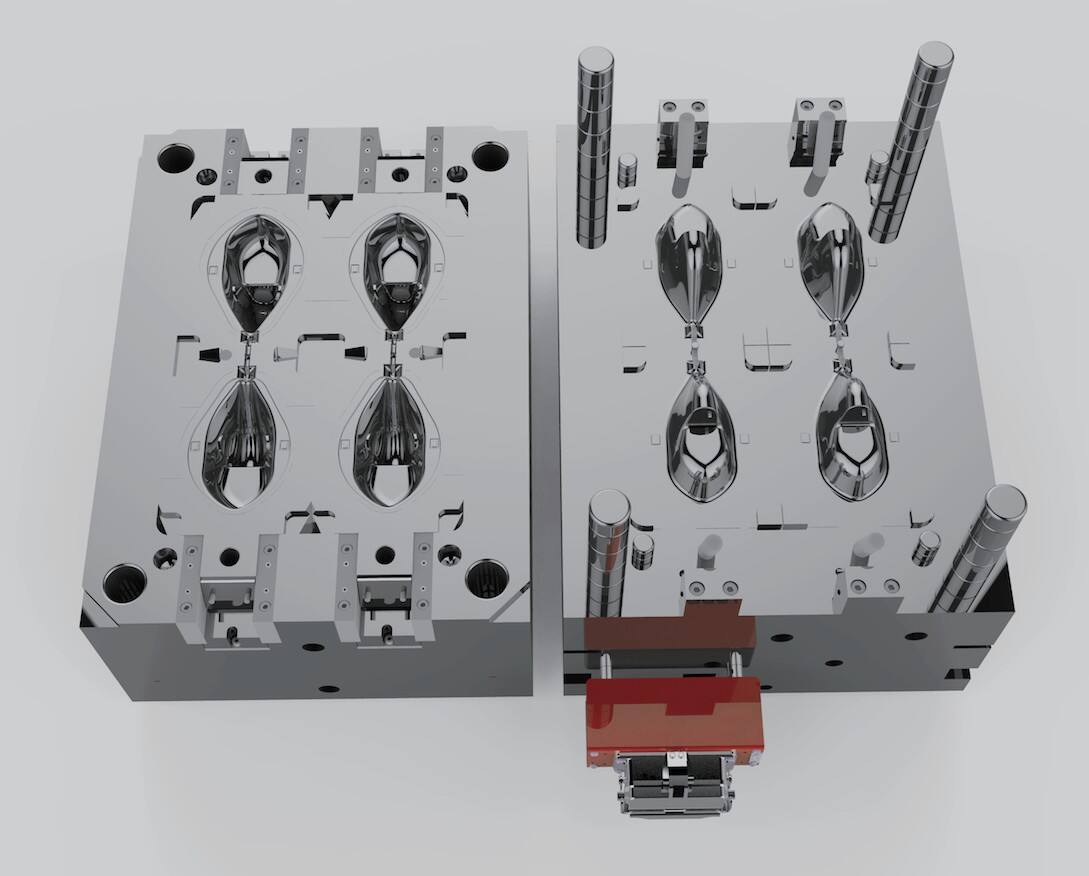

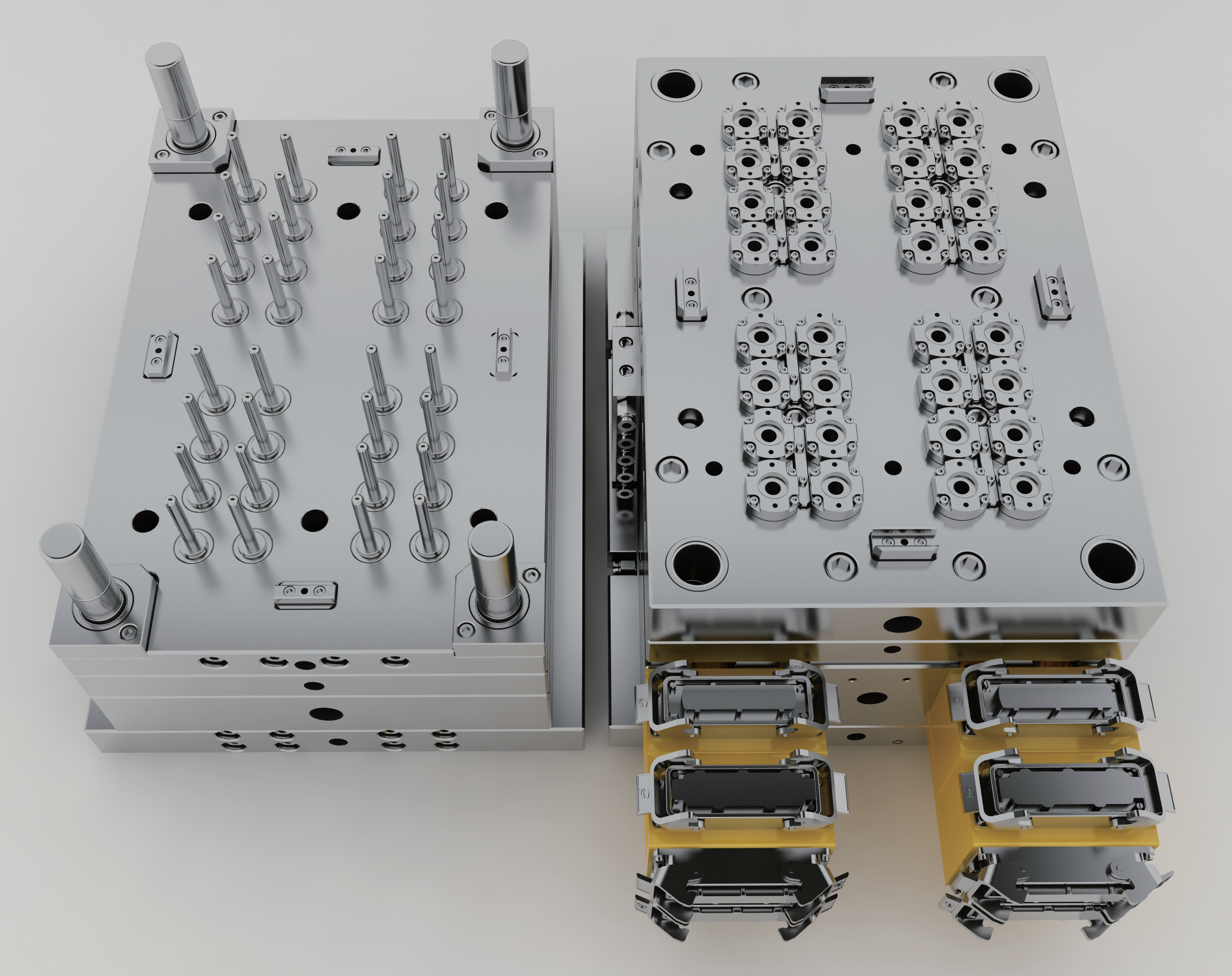

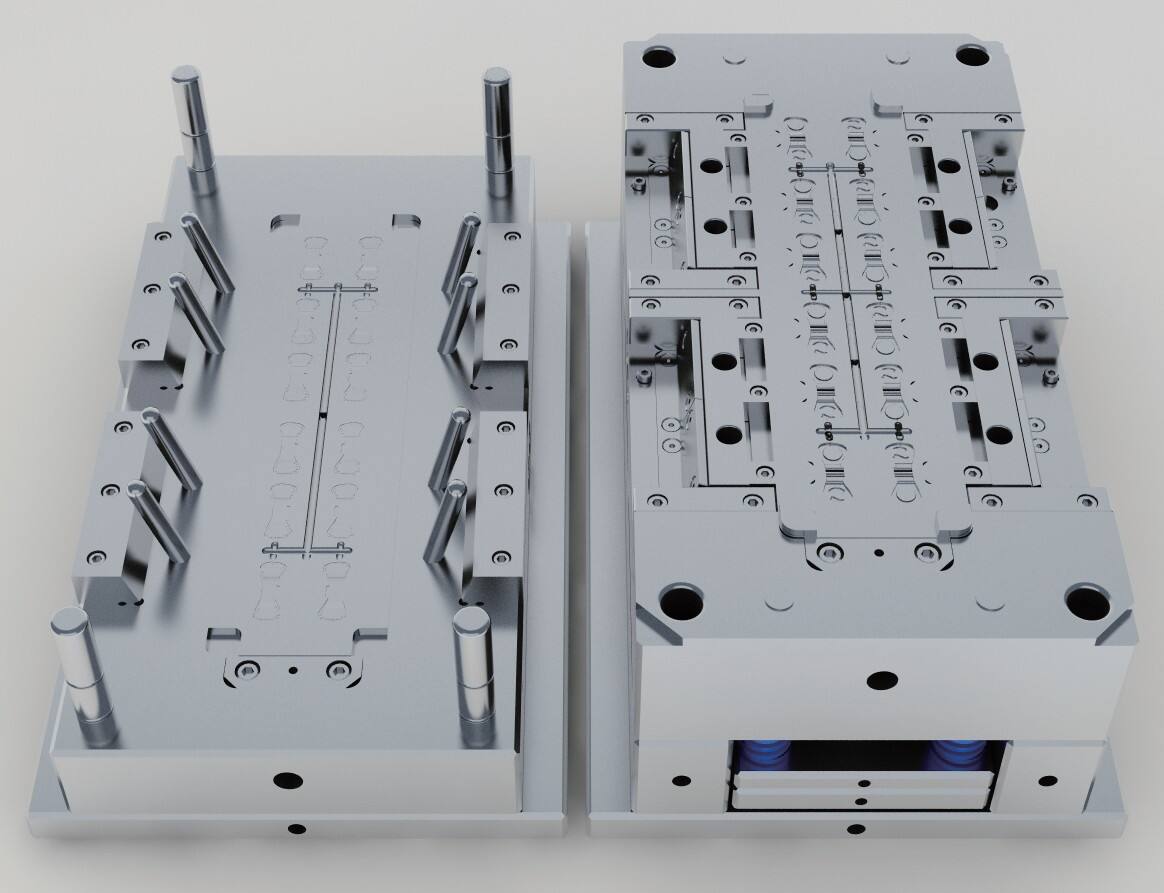

injection molding systems

Injection molding systems represent a cornerstone technology in modern manufacturing, offering a sophisticated method for producing high-quality plastic parts with exceptional precision and consistency. These systems operate by heating plastic material until it reaches a molten state, then injecting it under high pressure into carefully designed molds. The process is characterized by its ability to create complex geometries with tight tolerances, making it ideal for both small precision components and larger industrial parts. Modern injection molding systems incorporate advanced features such as digital control interfaces, automated material handling, and real-time monitoring capabilities. The technology utilizes various thermoplastic and thermosetting polymers, enabling manufacturers to select materials that best match their specific requirements for strength, flexibility, and durability. These systems excel in high-volume production scenarios, offering remarkable efficiency through rapid cycle times and minimal material waste. The versatility of injection molding systems extends across numerous industries, including automotive manufacturing, consumer electronics, medical devices, and household products. The technology's ability to maintain consistent quality while producing large quantities of parts has made it an indispensable tool in modern manufacturing operations.