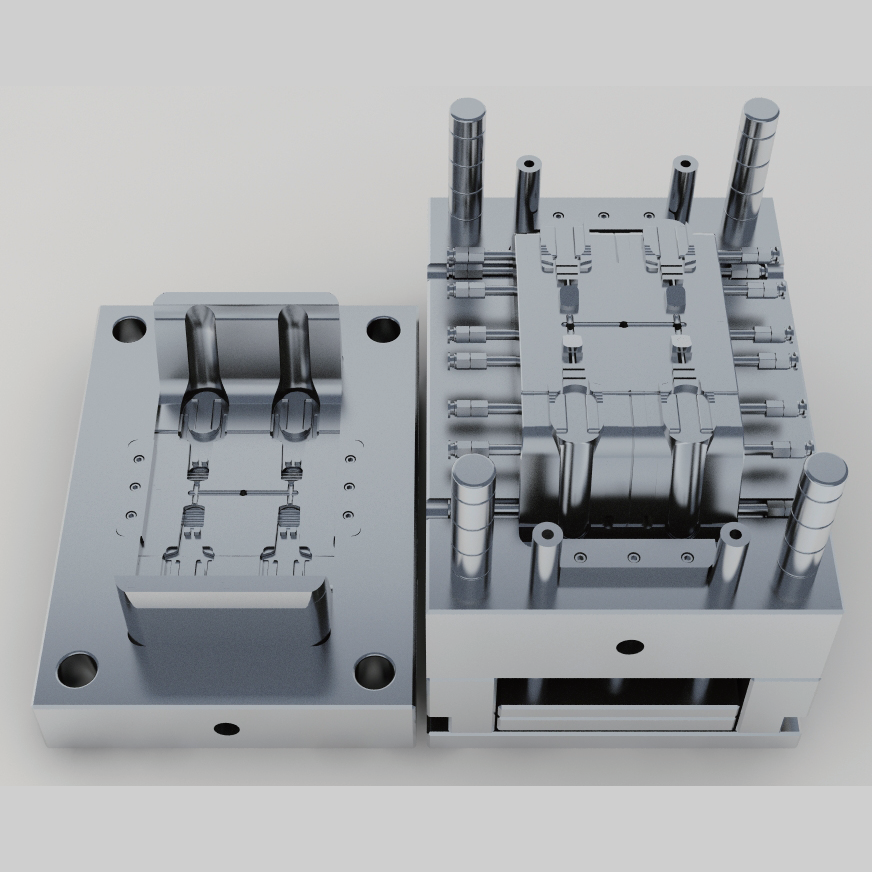

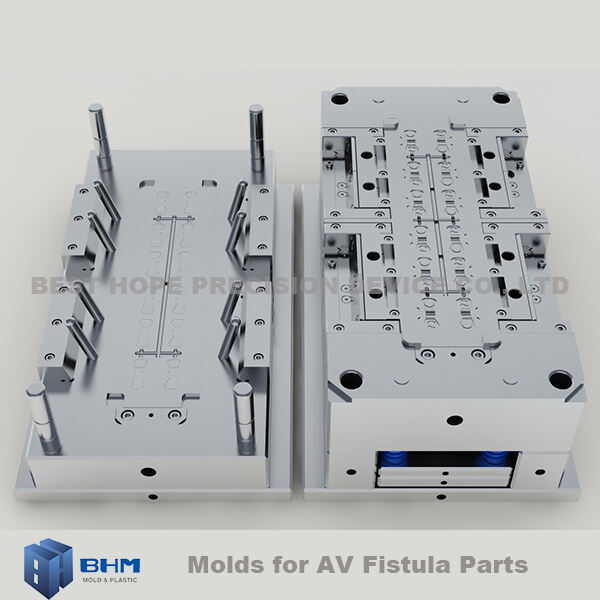

moulding maker

A moulding maker is an advanced manufacturing equipment designed to create precise and customized molds for various industrial applications. This sophisticated machine combines cutting-edge technology with precision engineering to produce high-quality molds efficiently and accurately. The system incorporates computer-numerical-control (CNC) capabilities, allowing for automated operations and precise dimensional control. It features multi-axis movement systems that enable complex geometrical shapes to be created with exceptional accuracy. The machine is equipped with advanced cooling systems to maintain optimal operating temperatures during extended production runs. Modern moulding makers include integrated quality control systems that monitor the entire manufacturing process, ensuring consistency and reducing waste. They can process various materials, including metals, plastics, and composites, making them versatile for different industry needs. The equipment's user-friendly interface allows operators to program and modify production parameters easily, while its robust construction ensures durability and long-term reliability. Safety features such as emergency stops and protective enclosures are standard, maintaining workplace safety while maximizing productivity.