plastic molding company

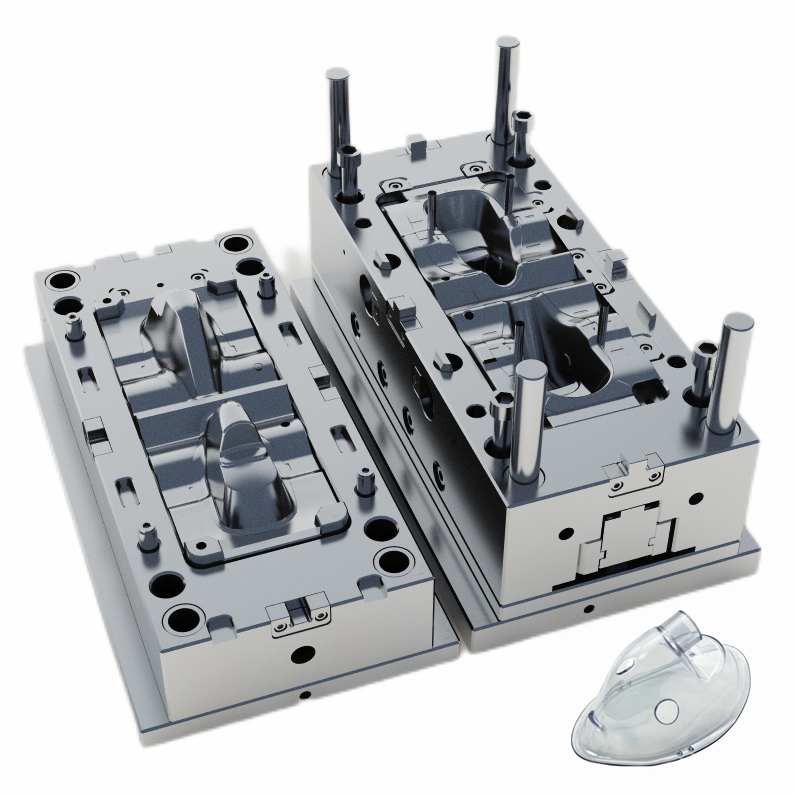

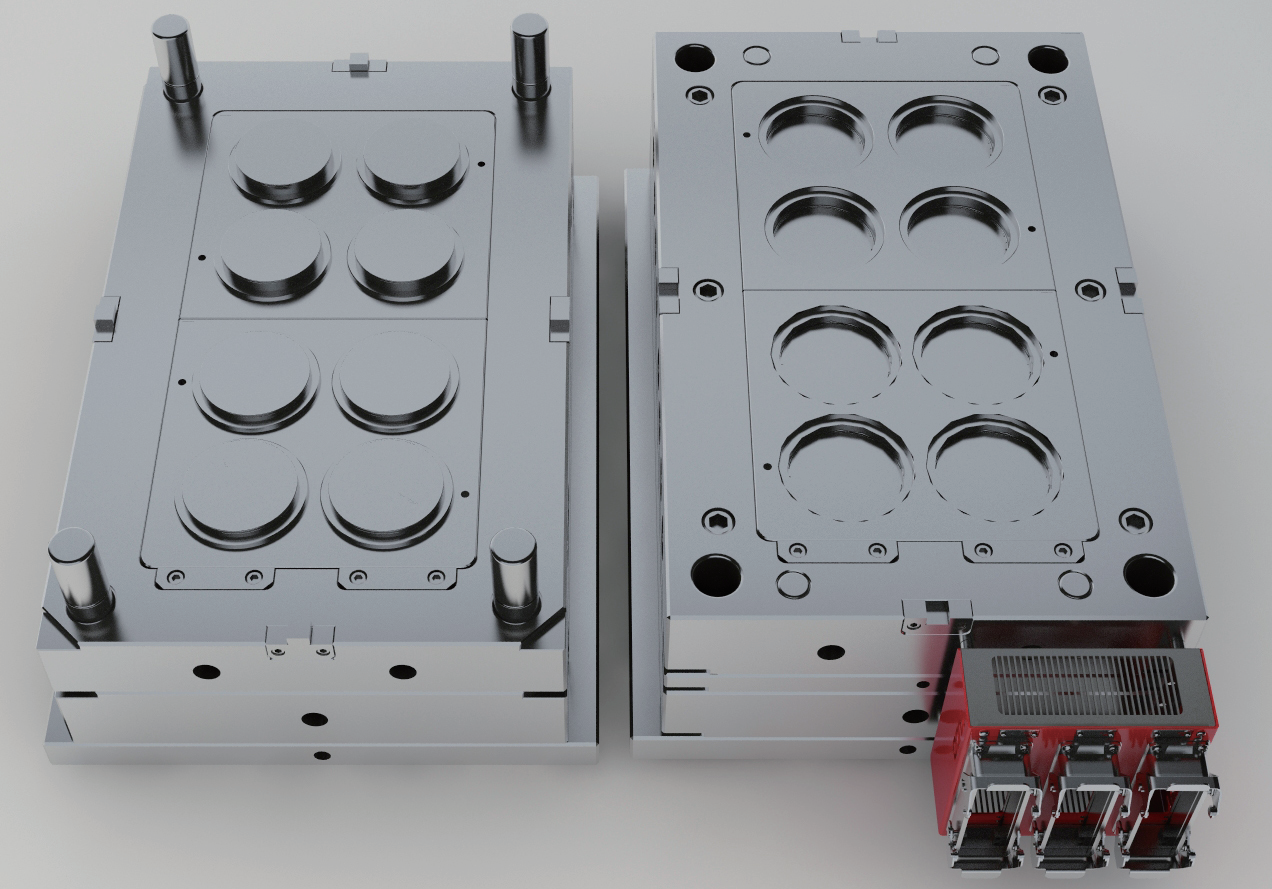

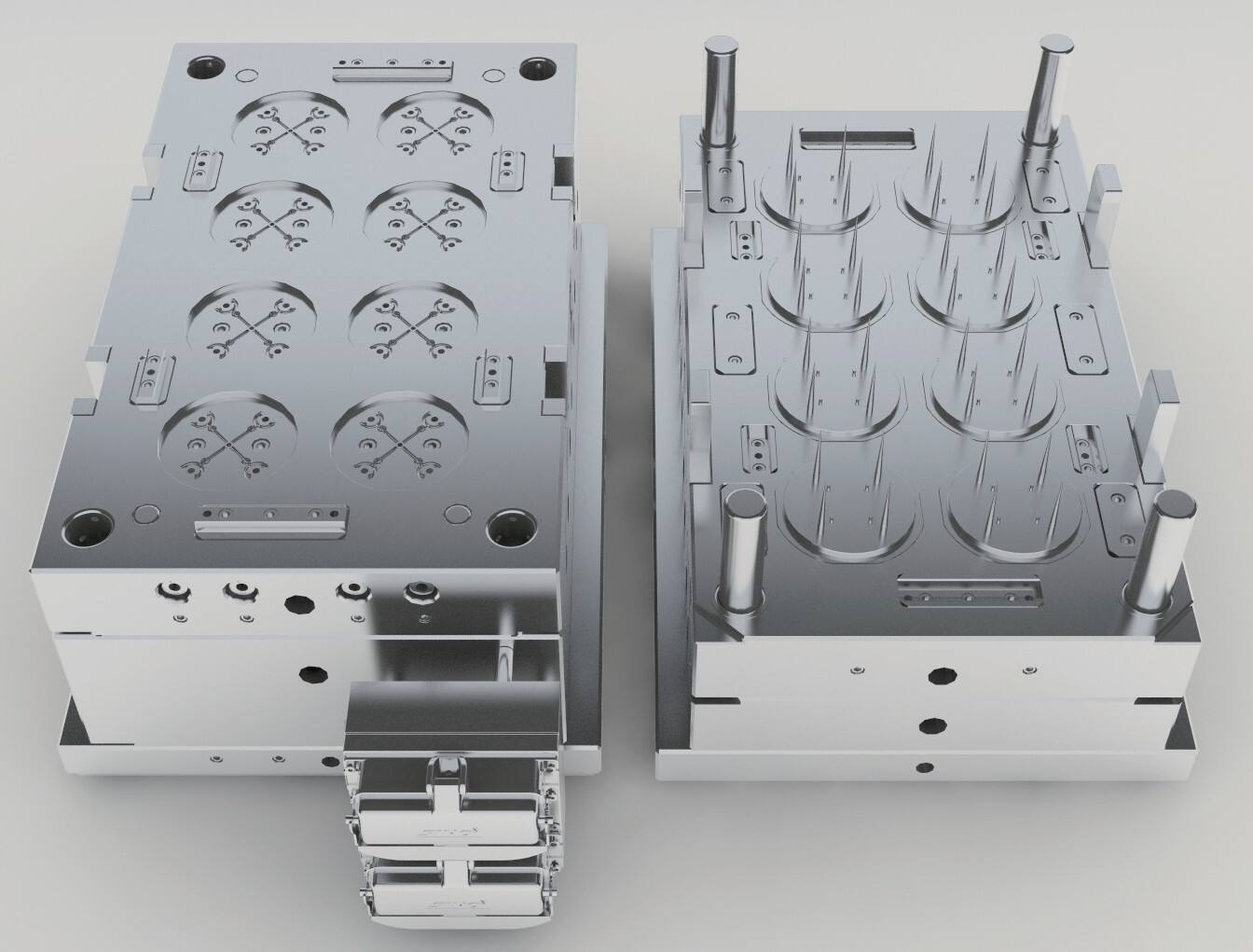

Our plastic molding company stands at the forefront of manufacturing excellence, offering comprehensive solutions for diverse industrial needs. We specialize in precision injection molding, utilizing state-of-the-art equipment and advanced manufacturing processes to deliver superior quality plastic components. Our facility houses modern injection molding machines ranging from 50 to 1000 tons, capable of producing parts varying from microscopic components to large-scale industrial pieces. We employ cutting-edge Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems, ensuring precise mold design and exceptional product quality. Our expertise extends across multiple industries, including automotive, medical devices, consumer electronics, and aerospace. We maintain stringent quality control measures throughout the production process, from material selection to final inspection. Our team of experienced engineers and technicians works collaboratively to optimize product design, reduce cycle times, and minimize material waste. We offer complete turnkey solutions, including mold design, prototype development, production molding, and assembly services. Our facility is equipped with advanced material handling systems and automated quality inspection equipment, ensuring consistent product quality and efficient production cycles.