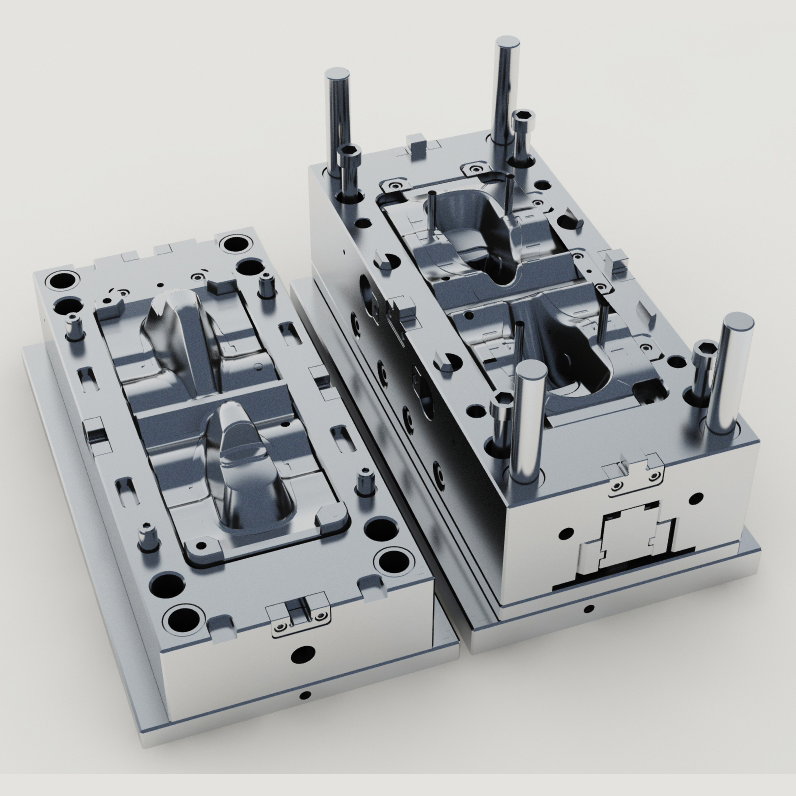

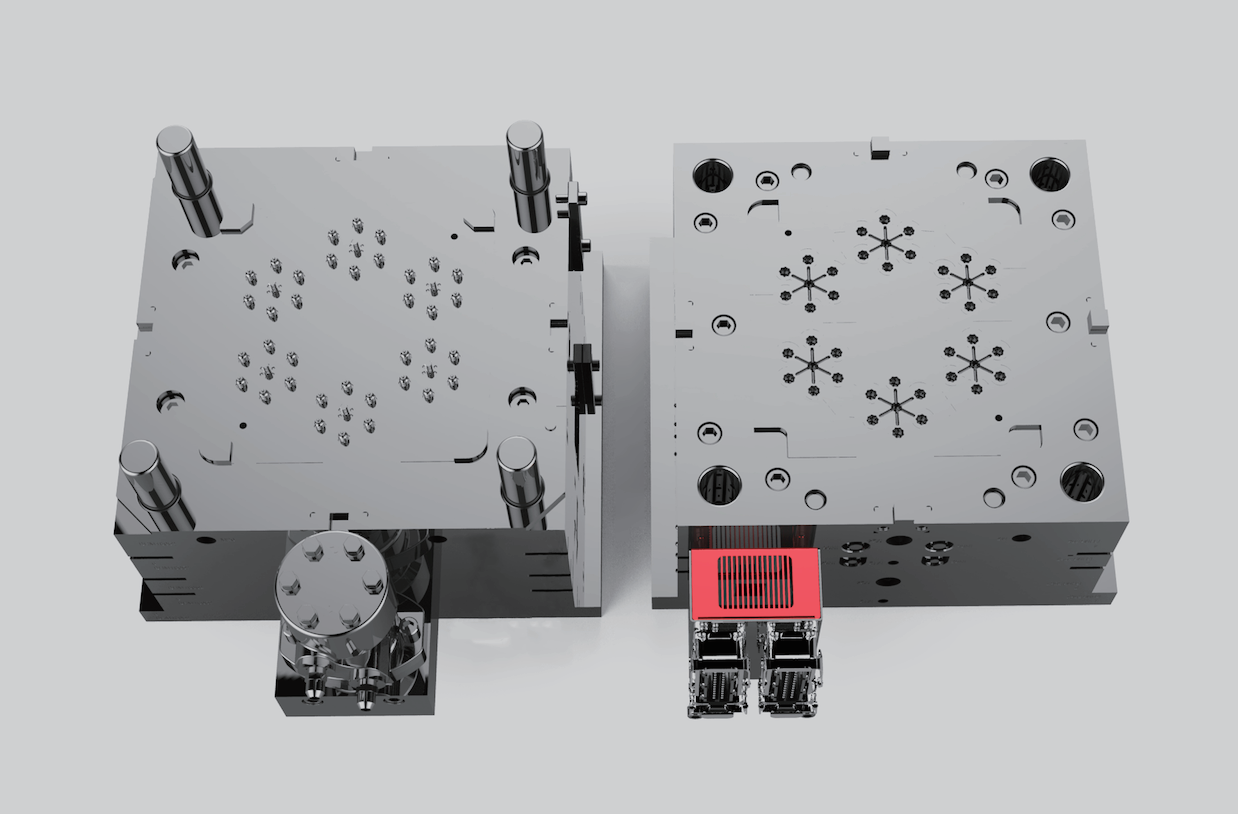

overmolding injection molding

Overmolding injection molding is an advanced manufacturing process that combines multiple materials into a single, integrated component through a sequential injection molding procedure. This innovative technique involves the creation of a base layer using one material, followed by the application of additional layers of different materials over the initial substrate. The process excels in producing parts with complex geometries, enhanced functionality, and improved ergonomic properties. The technology enables manufacturers to create products with varying material characteristics, such as rigid cores with soft-touch exteriors, in a single manufacturing cycle. This process is particularly valuable in industries requiring components with specific performance attributes, such as automotive parts, consumer electronics, medical devices, and sporting goods. The versatility of overmolding allows for the combination of materials with different physical properties, including hardness, flexibility, and chemical resistance. Modern overmolding systems utilize sophisticated control systems to ensure precise material distribution, temperature regulation, and pressure control throughout the molding cycle. This results in consistent product quality and reduced manufacturing costs compared to traditional assembly methods. The technology also supports sustainable manufacturing practices by minimizing material waste and enabling the creation of durable, long-lasting products.