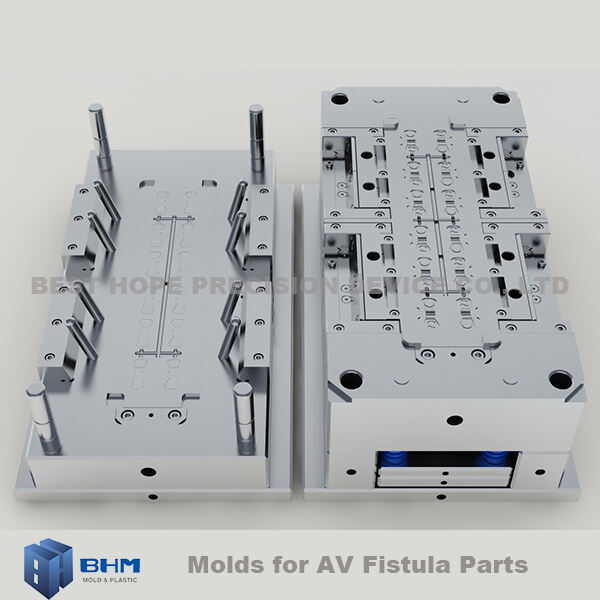

die for plastic moulding

A die for plastic moulding represents a crucial tool in modern manufacturing, engineered to shape molten plastic into precise, consistent products. This sophisticated piece of equipment consists of two main components, the cavity and the core, which work together to create the desired shape. The die's construction typically involves high-grade steel, carefully machined to exact specifications, ensuring longevity and precision in production. Advanced features include cooling channels that regulate temperature distribution, ejector systems for smooth product removal, and carefully designed gates for optimal material flow. The technology incorporates various venting mechanisms to prevent air traps and ensure complete filling of the mold cavity. Modern dies often feature interchangeable components, allowing for quick modifications and maintenance. These tools are essential in producing everything from small electronic components to large automotive parts, with applications spanning across industries including consumer goods, medical devices, and aerospace components. The precision engineering of these dies enables manufacturers to achieve tight tolerances, consistent quality, and high production rates while minimizing material waste and cycle times.