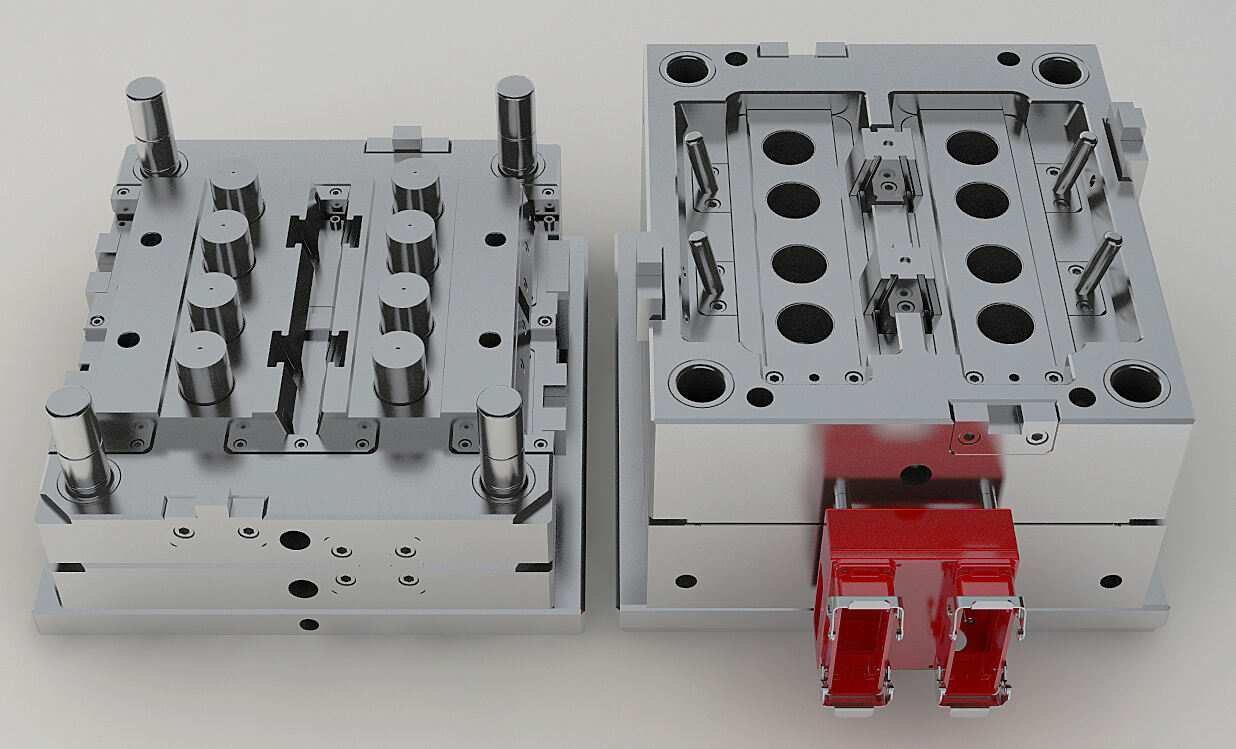

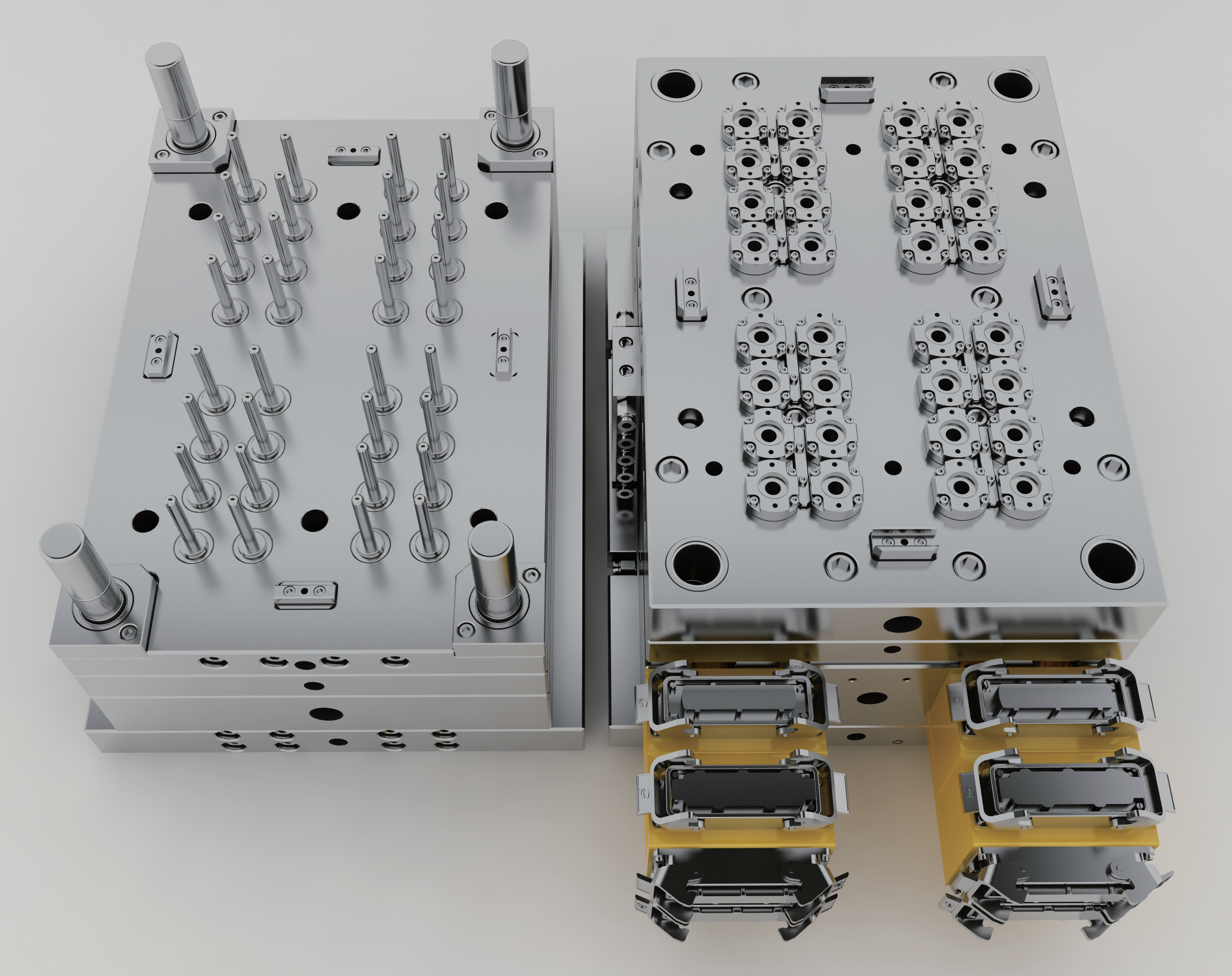

plastic injection

Plastic injection molding is a revolutionary manufacturing process that transforms raw plastic materials into precisely engineered products through a sophisticated combination of heat, pressure, and cooling. This versatile technology involves melting plastic pellets and injecting the molten material into carefully designed molds under high pressure. The process begins with the material selection, where thermoplastic pellets are fed into a heated barrel, converting them into a malleable state. The molten plastic is then forced into a custom mold cavity using a powerful screw mechanism, where it cools and solidifies into the desired shape. Modern plastic injection systems incorporate advanced features such as precise temperature control, automated material handling, and real-time quality monitoring to ensure consistent production. The technology finds extensive applications across various industries, including automotive parts manufacturing, consumer electronics, medical devices, and household products. Its ability to produce complex geometries with tight tolerances, while maintaining high production efficiency, makes it an indispensable process in modern manufacturing.