pvc injection

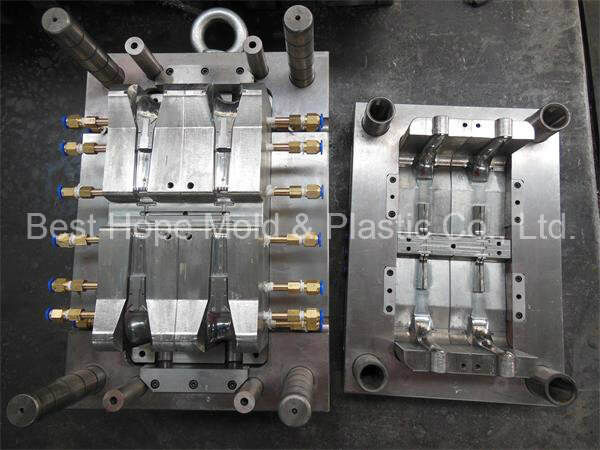

PVC injection is a sophisticated manufacturing process that transforms polyvinyl chloride (PVC) raw materials into diverse products through precision injection molding technology. This versatile method employs specialized machinery that heats PVC compounds to their optimal melting point before injecting them into carefully designed molds under high pressure. The process incorporates advanced temperature control systems, ensuring consistent material flow and preventing degradation. Modern PVC injection systems feature computerized controls for parameter adjustment, enabling manufacturers to achieve precise specifications in terms of product dimensions, surface finish, and material properties. The technology excels in producing complex geometries, thin-walled components, and intricate details that would be challenging to achieve through other manufacturing methods. Applications span across multiple industries, including construction, automotive, medical devices, and consumer goods. The process is particularly valued for its ability to create durable, weather-resistant products while maintaining cost-effectiveness in high-volume production scenarios. The technology also supports sustainable manufacturing practices through minimal material waste and the potential for recycling production scrap.