injection mold tooling cost

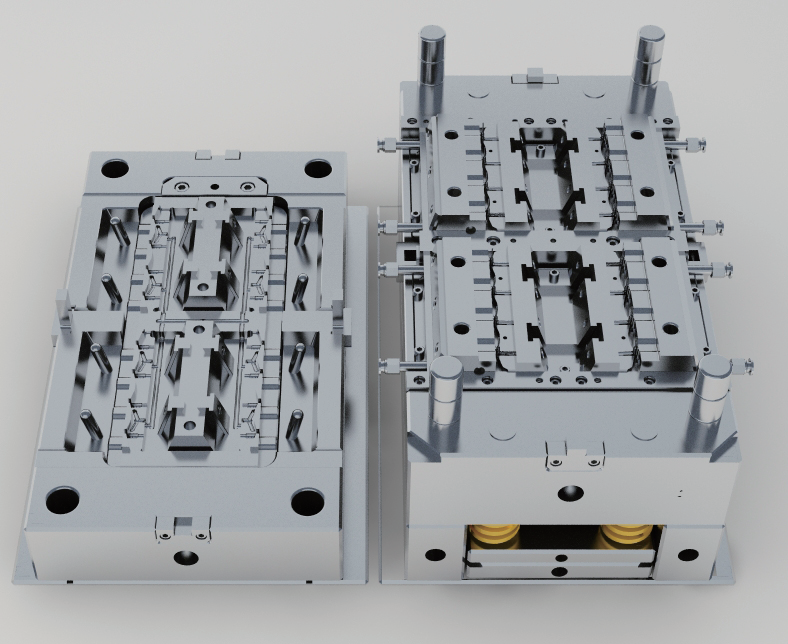

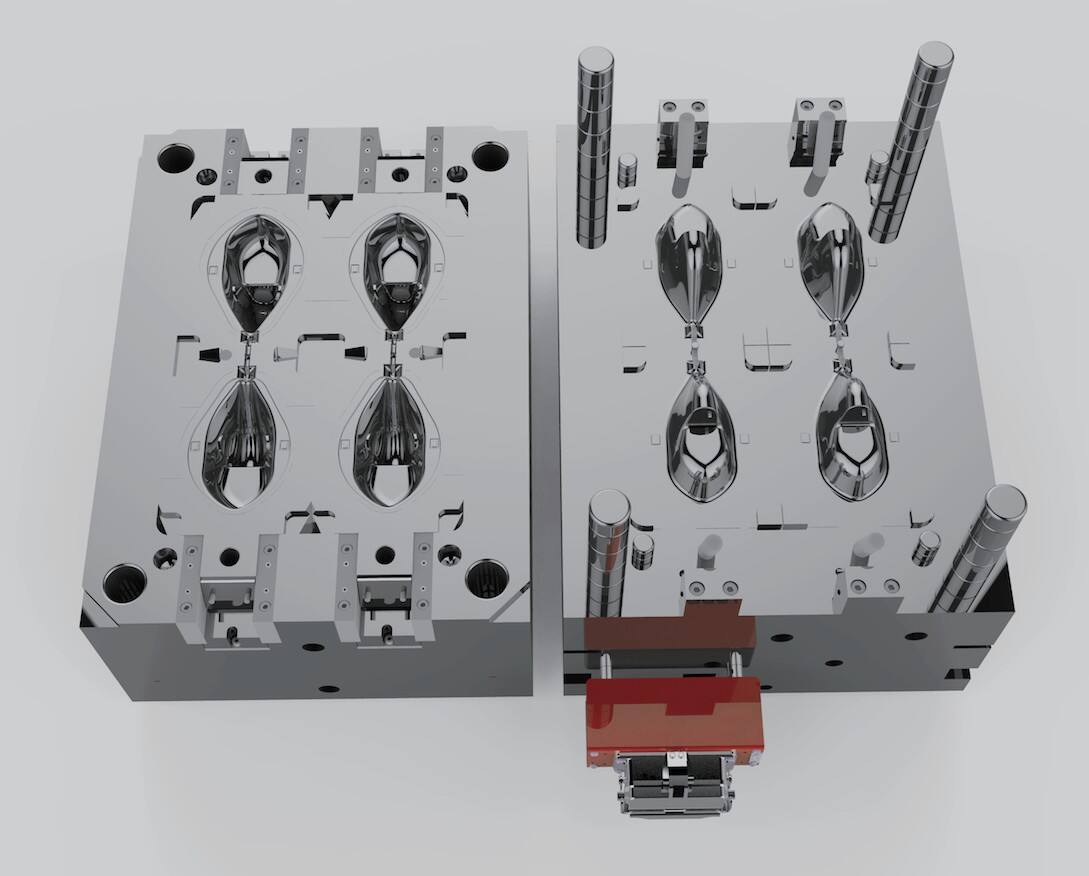

Injection mold tooling cost represents a crucial investment in manufacturing processes, encompassing various elements that determine the final expense of producing molds for plastic injection molding. This comprehensive cost structure includes material selection, design complexity, mold size, production volume requirements, and labor expenses. The tooling cost typically covers the entire process from initial design and engineering to final mold construction and testing. Modern injection mold tooling incorporates advanced technologies such as CAD/CAM systems, precision machining, and quality control measures to ensure optimal performance. The cost factors extend to considerations like cavity numbers, cooling systems, ejection mechanisms, and surface finishing requirements. Manufacturing facilities must carefully evaluate these components to balance quality requirements with budget constraints. The investment in proper tooling directly impacts product quality, production efficiency, and long-term manufacturing success. Understanding these costs helps businesses make informed decisions about their manufacturing processes and maintain competitive advantages in their respective markets.