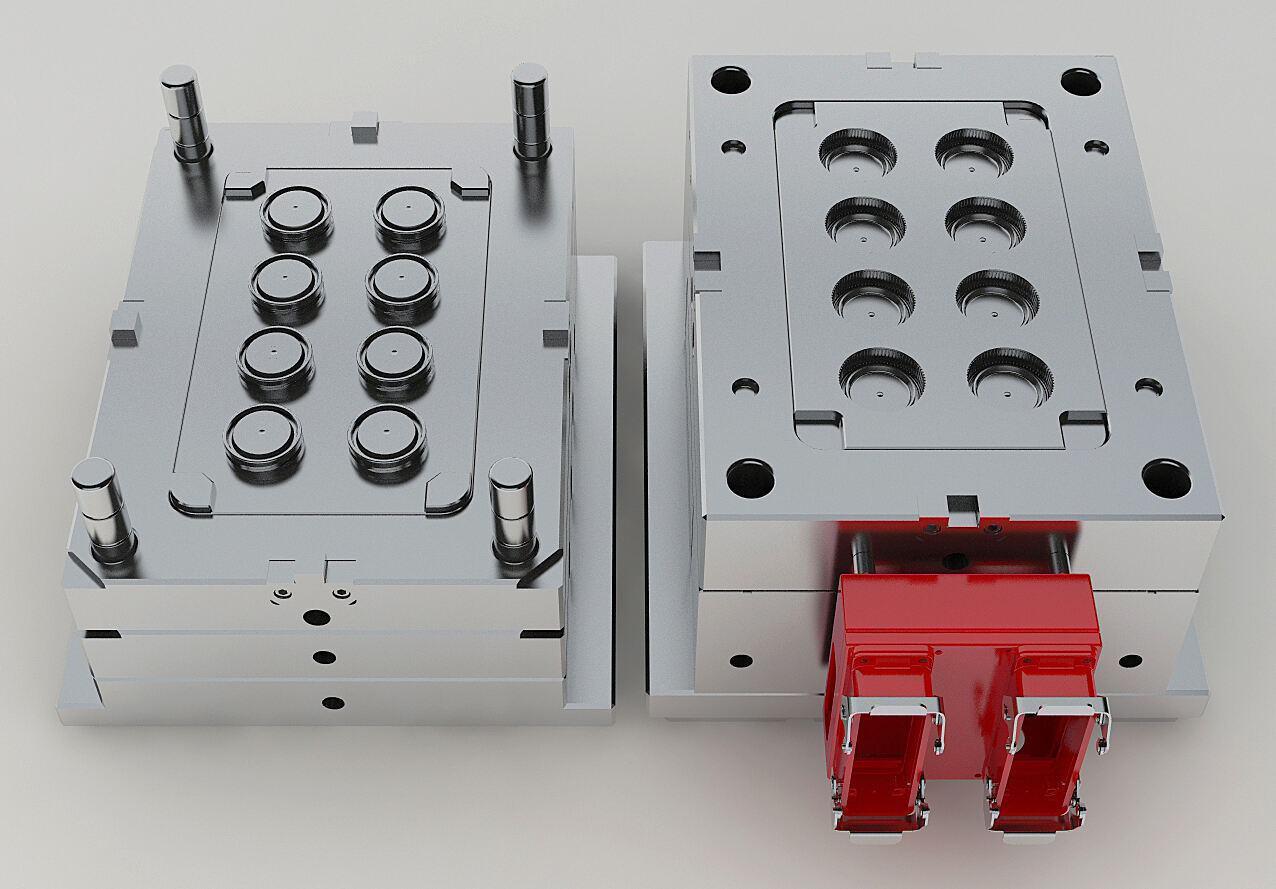

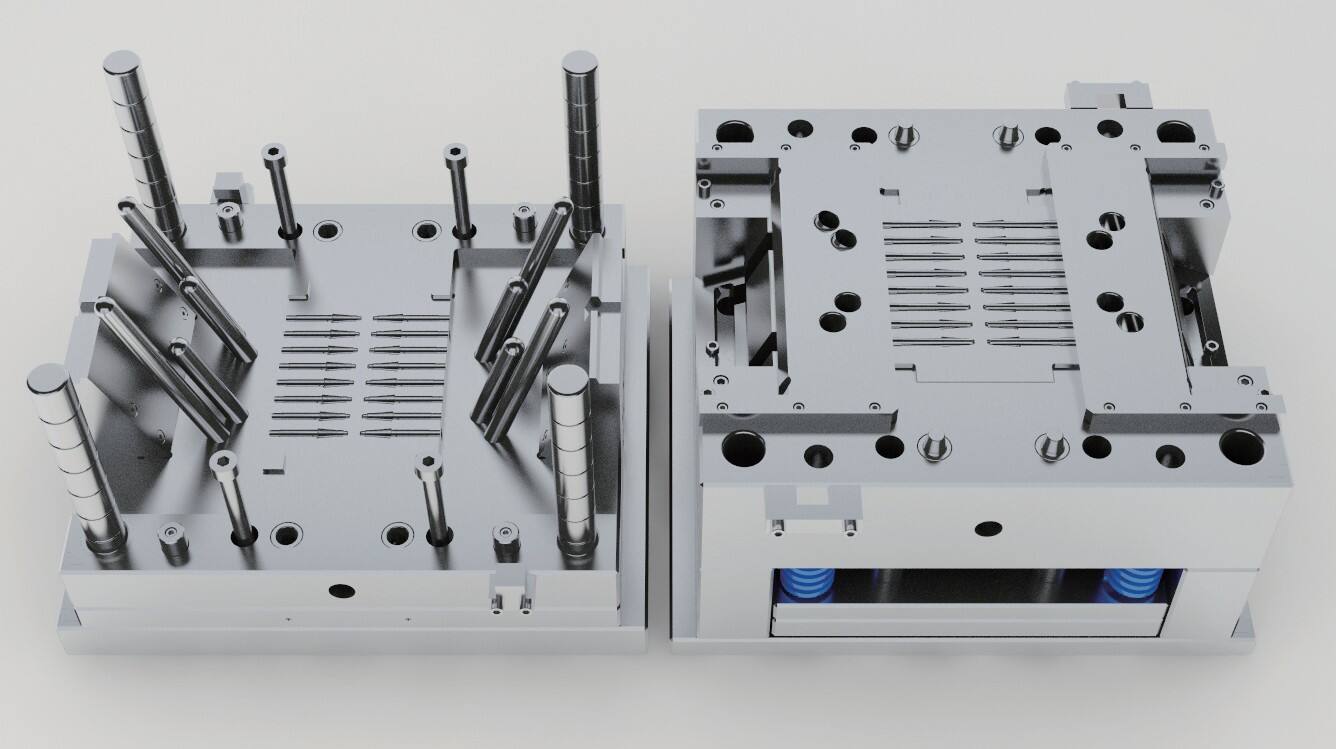

precision injection molding

Precision injection molding represents a cutting-edge manufacturing process that delivers exceptional accuracy and consistency in producing complex plastic components. This sophisticated technology utilizes advanced computer-controlled systems to inject molten plastic material into precisely engineered molds under carefully regulated pressure and temperature conditions. The process excels in creating intricate parts with tight tolerances, often as precise as +/- 0.001 inches, making it ideal for industries requiring high-precision components. The technology incorporates state-of-the-art sensors and monitoring systems that ensure optimal material flow, pressure distribution, and cooling rates, resulting in consistently high-quality outputs. Modern precision injection molding machines feature advanced automation capabilities, real-time quality control systems, and sophisticated material handling mechanisms. These systems can accommodate a wide range of thermoplastic and thermosetting materials, enabling the production of components with various physical properties and characteristics. The technology finds extensive applications in medical devices, automotive components, consumer electronics, aerospace parts, and other industries where precision and reliability are paramount. The process also supports various surface finishes and textures, allowing for both functional and aesthetic customization of molded parts.