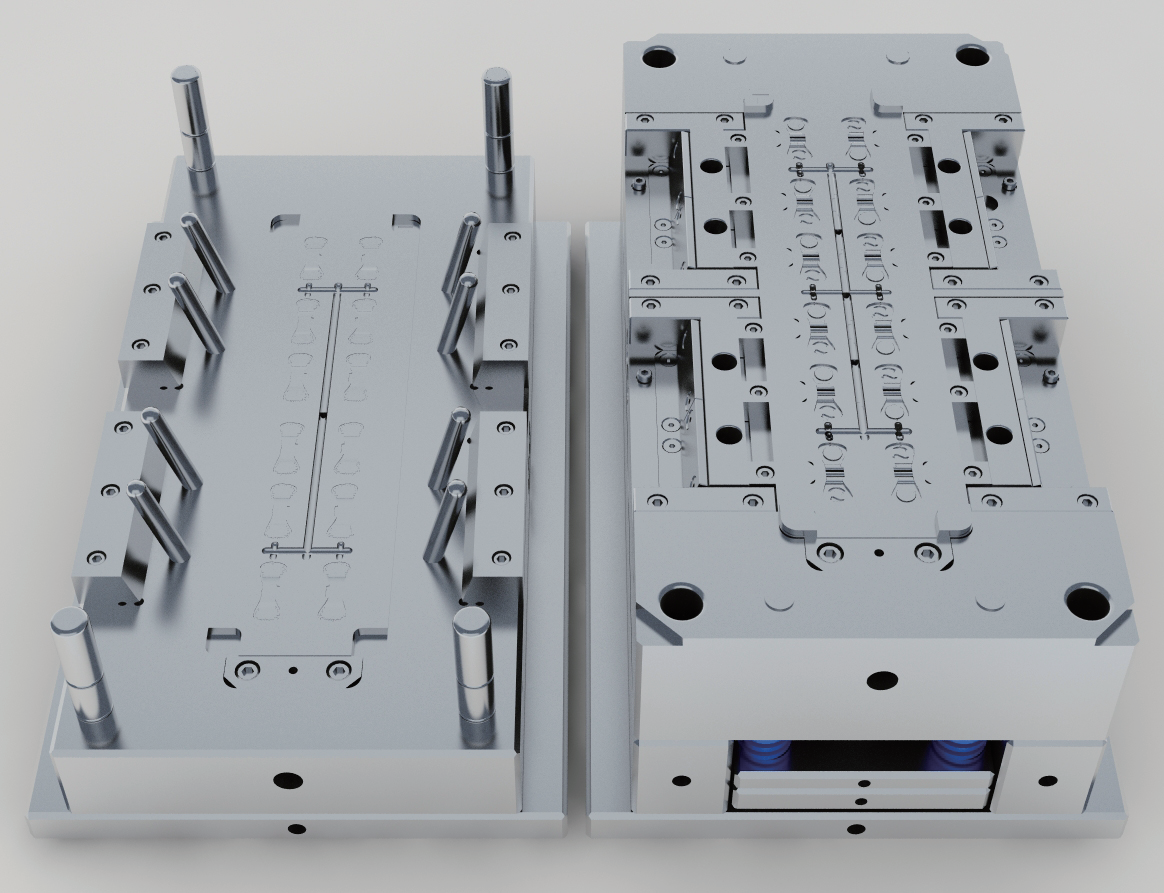

short shot injection molding

Short shot injection molding is a sophisticated manufacturing technique that involves deliberately under-filling the mold cavity during the injection molding process. This method creates partially filled parts with specific unfilled areas, which serves various quality control and manufacturing purposes. The process involves precisely controlling the amount of molten plastic injected into the mold, typically using between 70% to 95% of the total cavity volume. This technique is particularly valuable for troubleshooting mold filling issues, analyzing flow patterns, and optimizing process parameters. The technology incorporates advanced sensing systems and precise control mechanisms to ensure consistent and repeatable short shots. It finds extensive applications in quality testing, process validation, and product development across various industries, including automotive, medical devices, and consumer electronics. The method allows engineers to visualize how plastic flows through the mold, identify potential defects, and optimize gate locations and processing conditions. Additionally, short shot injection molding serves as an essential tool for validating simulation results and conducting material flow studies, making it an invaluable technique in modern plastic manufacturing.