injection molding factory

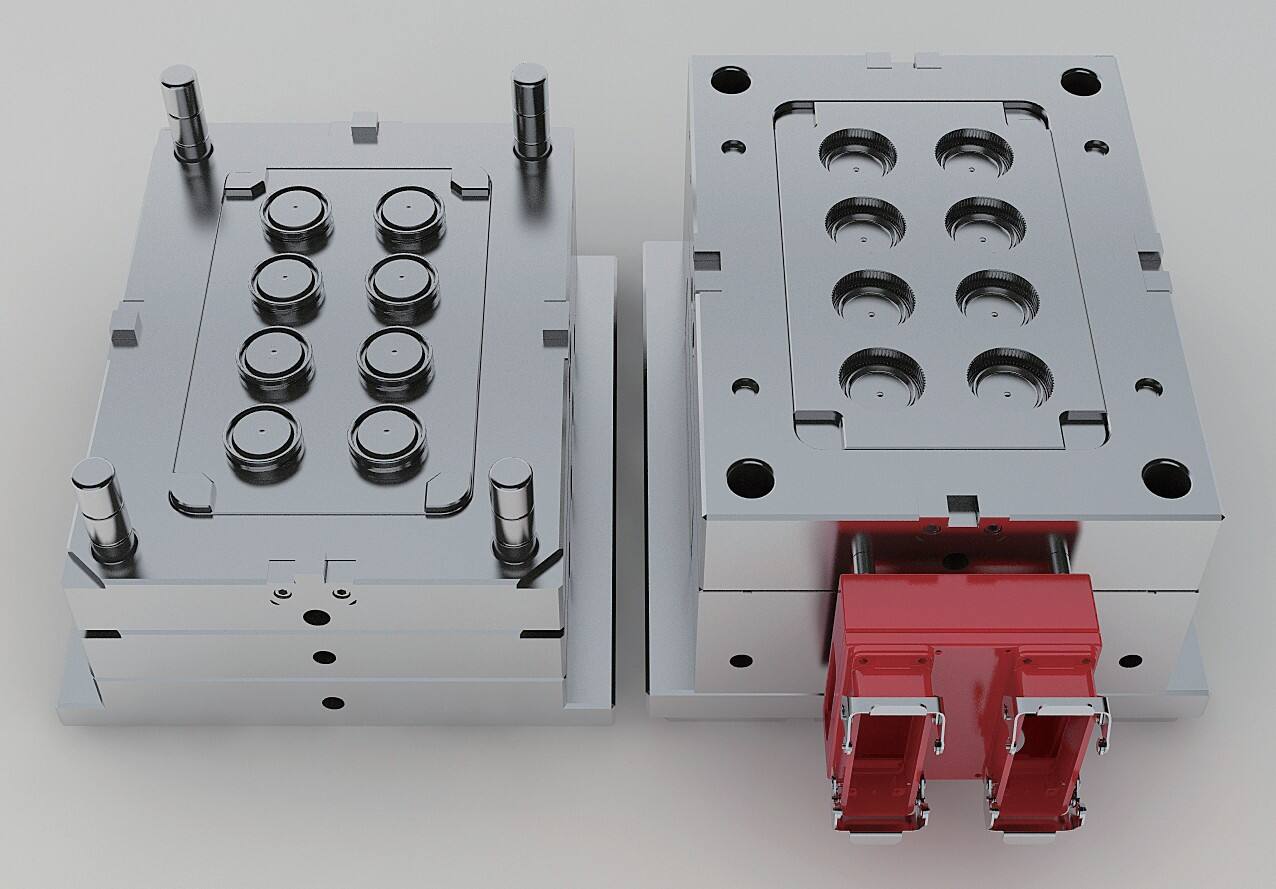

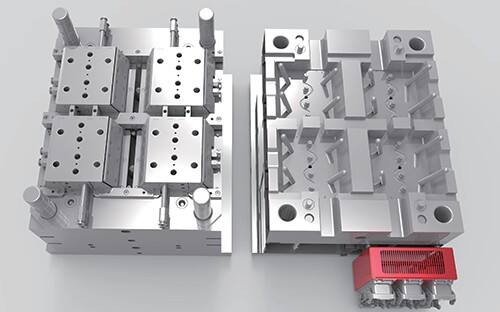

An injection molding factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality plastic components through precision engineering. These facilities house advanced machinery capable of creating complex parts with exceptional accuracy and consistency. The factory typically features multiple injection molding machines, ranging from small to large tonnage capabilities, allowing for versatile production needs. At its core, the facility operates using sophisticated control systems that monitor and regulate critical parameters such as temperature, pressure, and cycle times. The production floor incorporates automated material handling systems, ensuring efficient raw material management and consistent product quality. Quality control stations equipped with modern testing equipment maintain strict adherence to manufacturing standards. The factory's layout optimizes workflow, from material storage through production to finished product packaging. Climate-controlled environments protect sensitive materials and ensure consistent production conditions. Supplementary systems include water cooling towers, compressed air systems, and material drying equipment. The facility also maintains dedicated areas for mold storage and maintenance, crucial for sustaining continuous production operations. Advanced robotics systems handle part removal and secondary operations, while integrated conveyor systems facilitate smooth material flow throughout the facility.