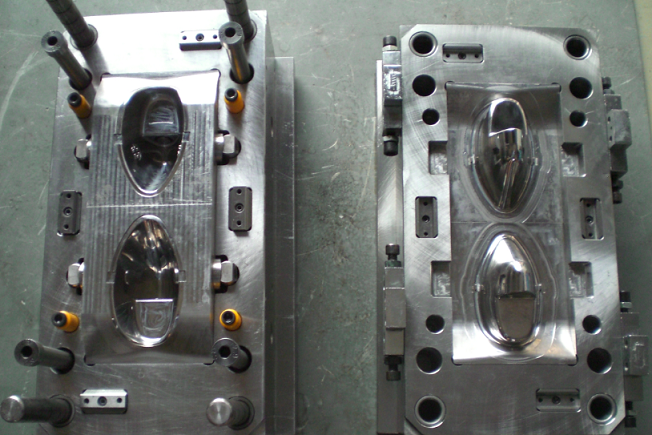

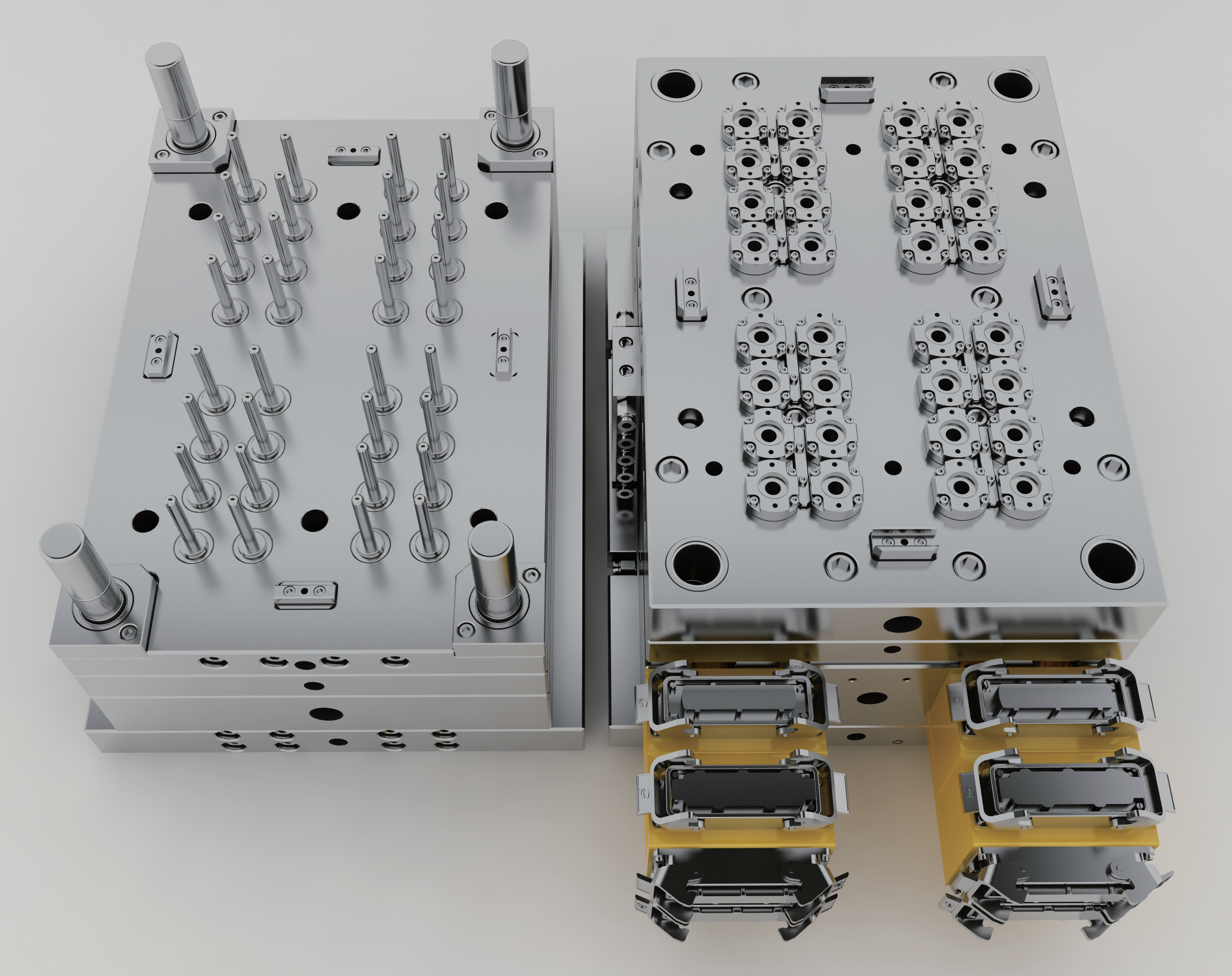

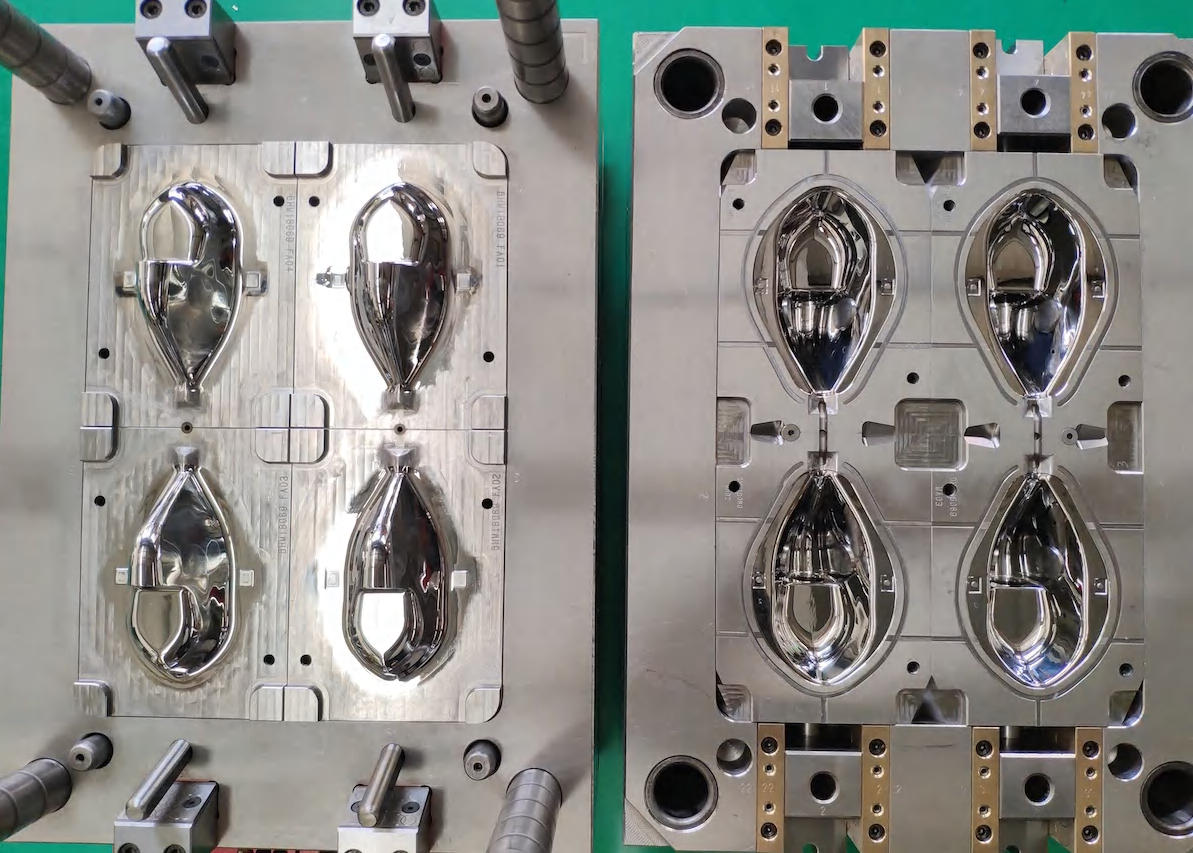

high volume injection molding

High volume injection molding is a sophisticated manufacturing process designed to produce large quantities of plastic parts with exceptional precision and consistency. This advanced manufacturing method utilizes specialized machinery and automated systems to inject molten plastic material into carefully engineered molds at high speeds and pressures. The process is specifically optimized for mass production, capable of producing thousands of identical parts per hour while maintaining strict quality standards. The technology incorporates advanced features such as multi-cavity molds, hot runner systems, and precise temperature control mechanisms to ensure optimal production efficiency. It's particularly well-suited for industries requiring large quantities of standardized components, such as automotive parts, consumer electronics, medical devices, and packaging materials. The process employs advanced monitoring systems and quality control measures to maintain consistent part quality throughout extended production runs. Modern high volume injection molding systems also integrate smart manufacturing capabilities, including real-time process monitoring, automated material handling, and predictive maintenance features to maximize uptime and productivity.