micro injection molding

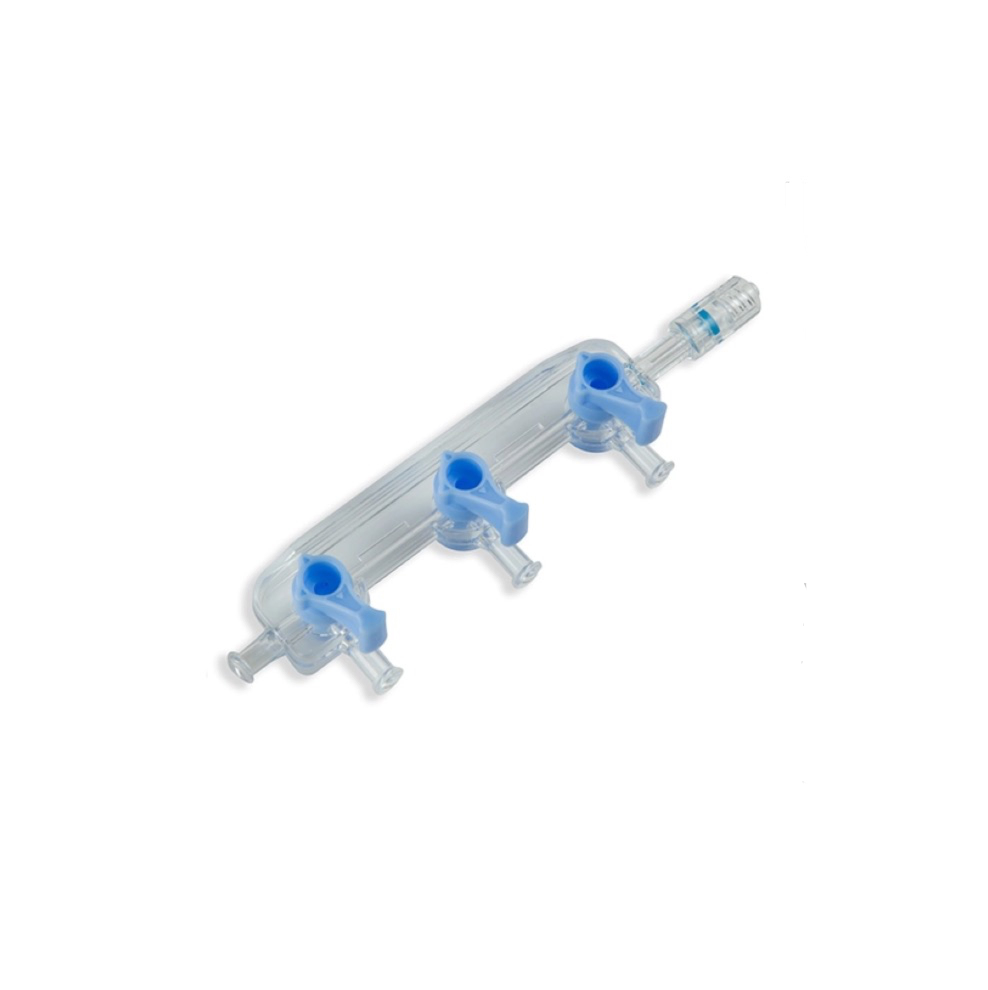

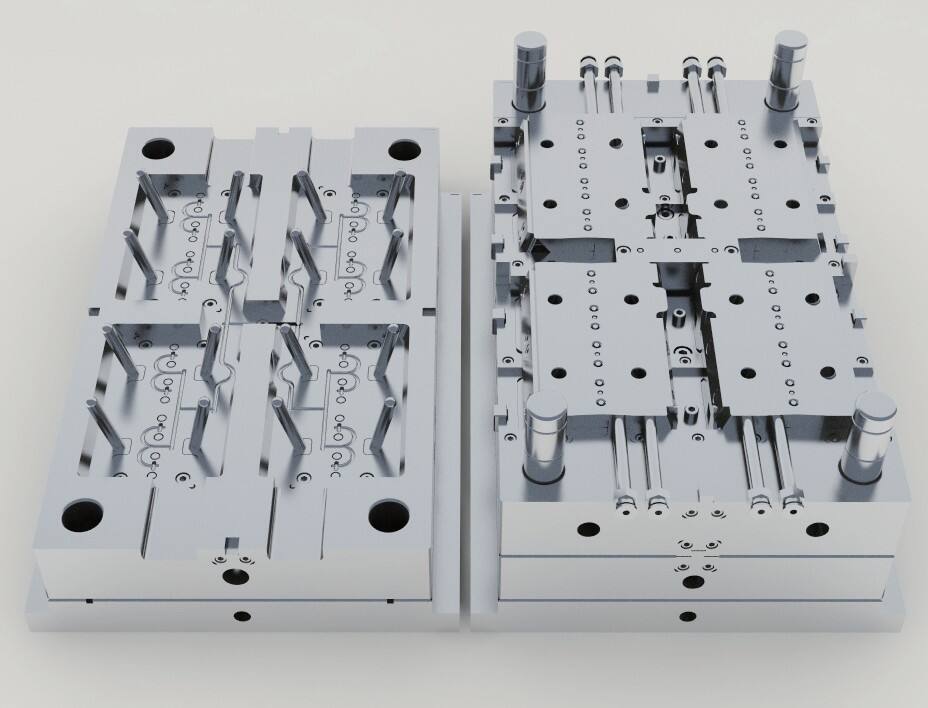

Micro injection molding is an advanced manufacturing process that enables the production of extremely small, high precision plastic components with intricate features, often measuring less than 1mm in size. This cutting edge technology utilizes specialized equipment and processes to inject molten thermoplastic materials into micro scaled molds under precisely controlled conditions. The process combines traditional injection molding principles with sophisticated engineering to achieve unprecedented levels of detail and accuracy. Modern micro injection molding systems incorporate advanced features such as precise temperature control, ultra high injection speeds, and specialized vacuum systems to ensure complete mold filling at the microscopic level. The technology finds extensive applications across various industries, including medical devices, electronics, telecommunications, and biotechnology. It enables the production of components like micro gears, connectors, sensors, and medical implants with tolerances as tight as 0.005mm. The process is particularly valuable for manufacturing complex geometric shapes and incorporating multiple features into a single component, which would be impossible to achieve through conventional manufacturing methods.