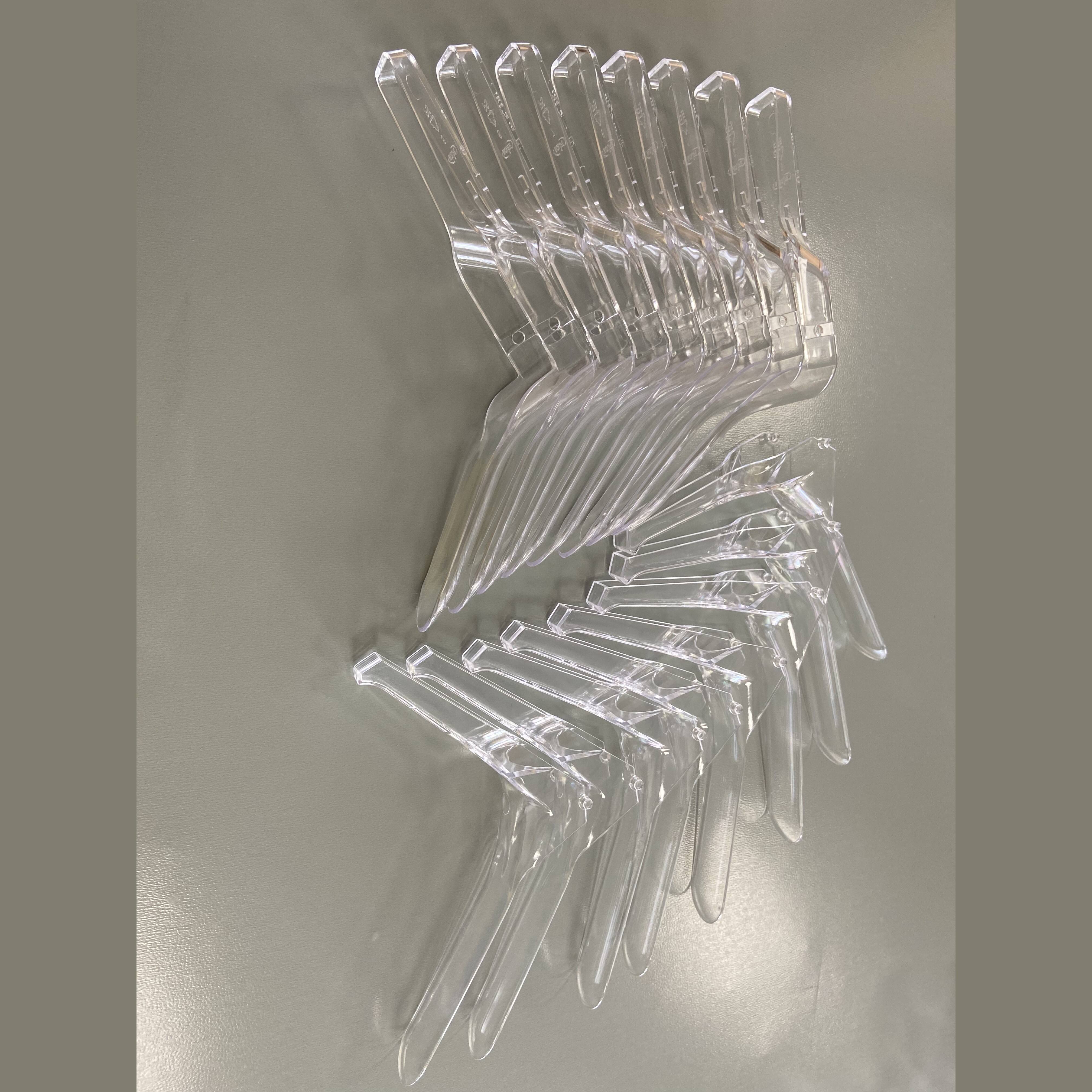

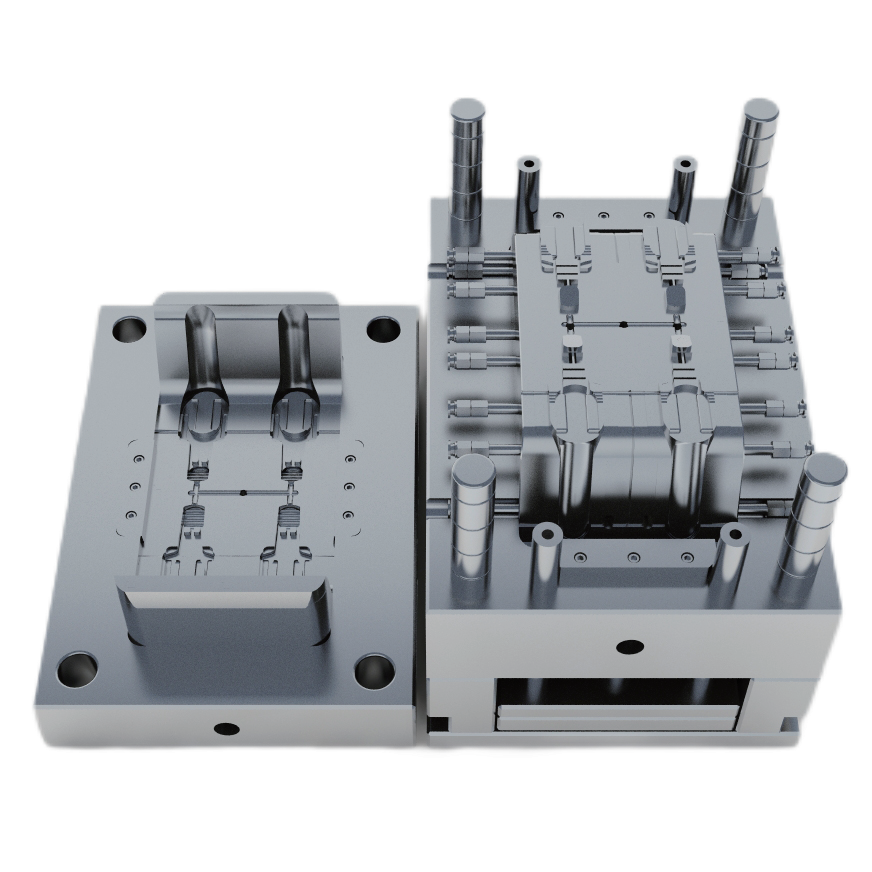

injection molded parts

Injection molded parts represent a cornerstone of modern manufacturing, offering precision-engineered components through a sophisticated process of material injection and cooling. These parts are created by injecting molten materials, typically thermoplastics, into carefully designed molds under high pressure. The process allows for the production of complex geometries with exceptional dimensional accuracy and surface finish. The technology behind injection molded parts has evolved significantly, incorporating advanced features such as gas-assisted injection, multi-material molding, and in-mold decorating capabilities. These parts find extensive applications across various industries, from automotive components and consumer electronics to medical devices and aerospace parts. The versatility of injection molding enables manufacturers to produce both small, intricate components and large structural parts with consistent quality. The process accommodates a wide range of materials, including engineering-grade plastics, thermoplastic elastomers, and fiber-reinforced composites, each selected based on specific performance requirements. Modern injection molded parts often integrate sophisticated design elements such as snap-fits, living hinges, and thread details, eliminating the need for secondary operations and reducing assembly costs.