injection molding medical plastics

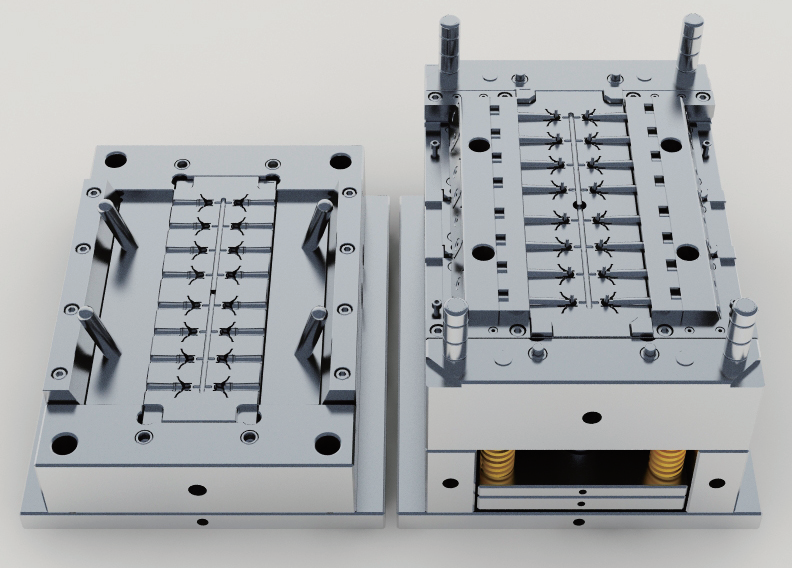

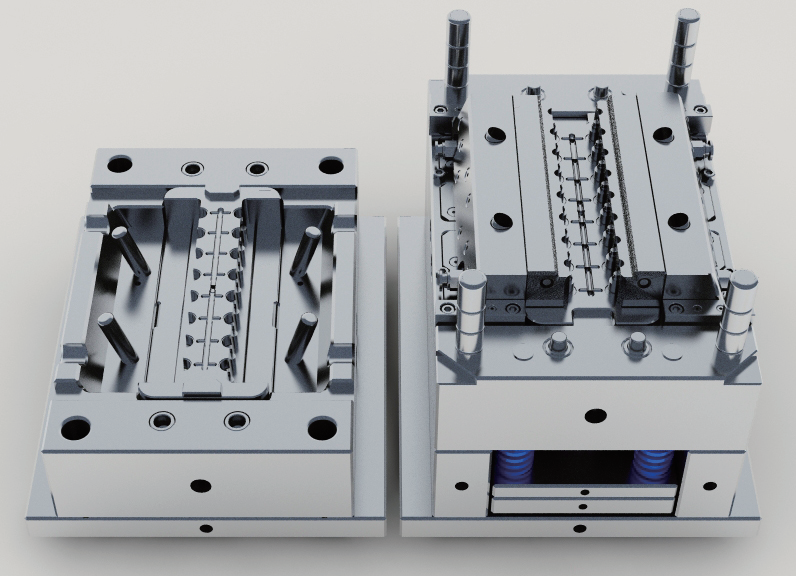

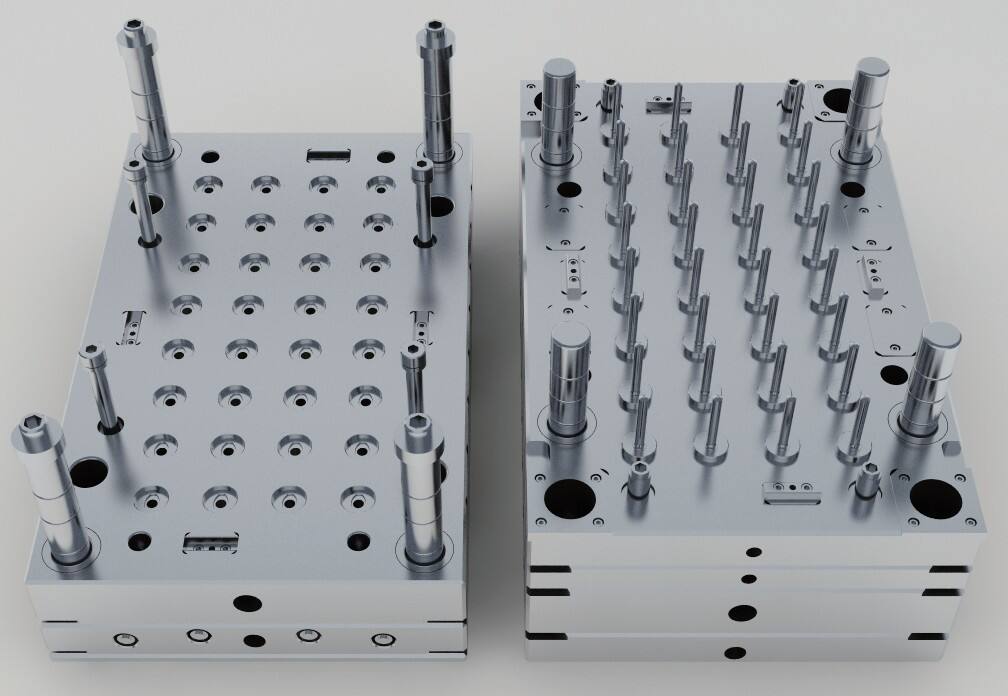

Injection molding medical plastics represents a cutting-edge manufacturing process that combines precision engineering with advanced materials science to produce high-quality medical devices and components. This sophisticated technology enables the creation of complex medical parts with exceptional accuracy and consistency, meeting the stringent requirements of the healthcare industry. The process involves heating plastic materials to their melting point, injecting them into carefully designed molds under high pressure, and allowing them to cool and solidify into the desired shape. This method is particularly valuable in medical applications due to its ability to maintain sterile conditions throughout production, ensure material purity, and achieve tight tolerances essential for medical devices. The technology accommodates a wide range of medical-grade plastics, including polycarbonate, polyethylene, and polypropylene, each selected for specific applications based on their properties. These materials undergo rigorous testing and certification to meet regulatory standards, ensuring their safety for medical use. The versatility of injection molding allows for the production of everything from simple components like surgical instruments and medication containers to complex medical devices and implants.