injection molding services

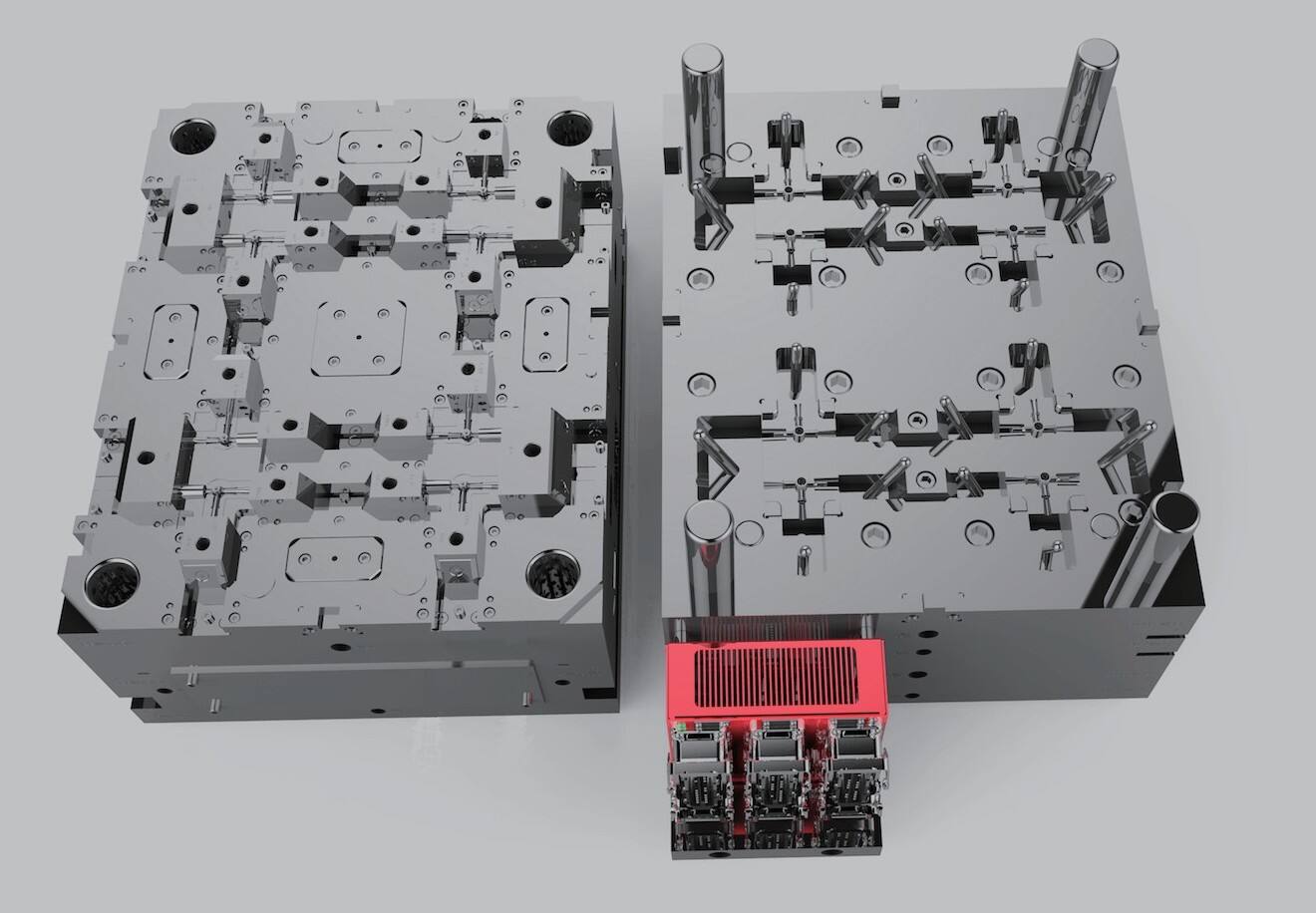

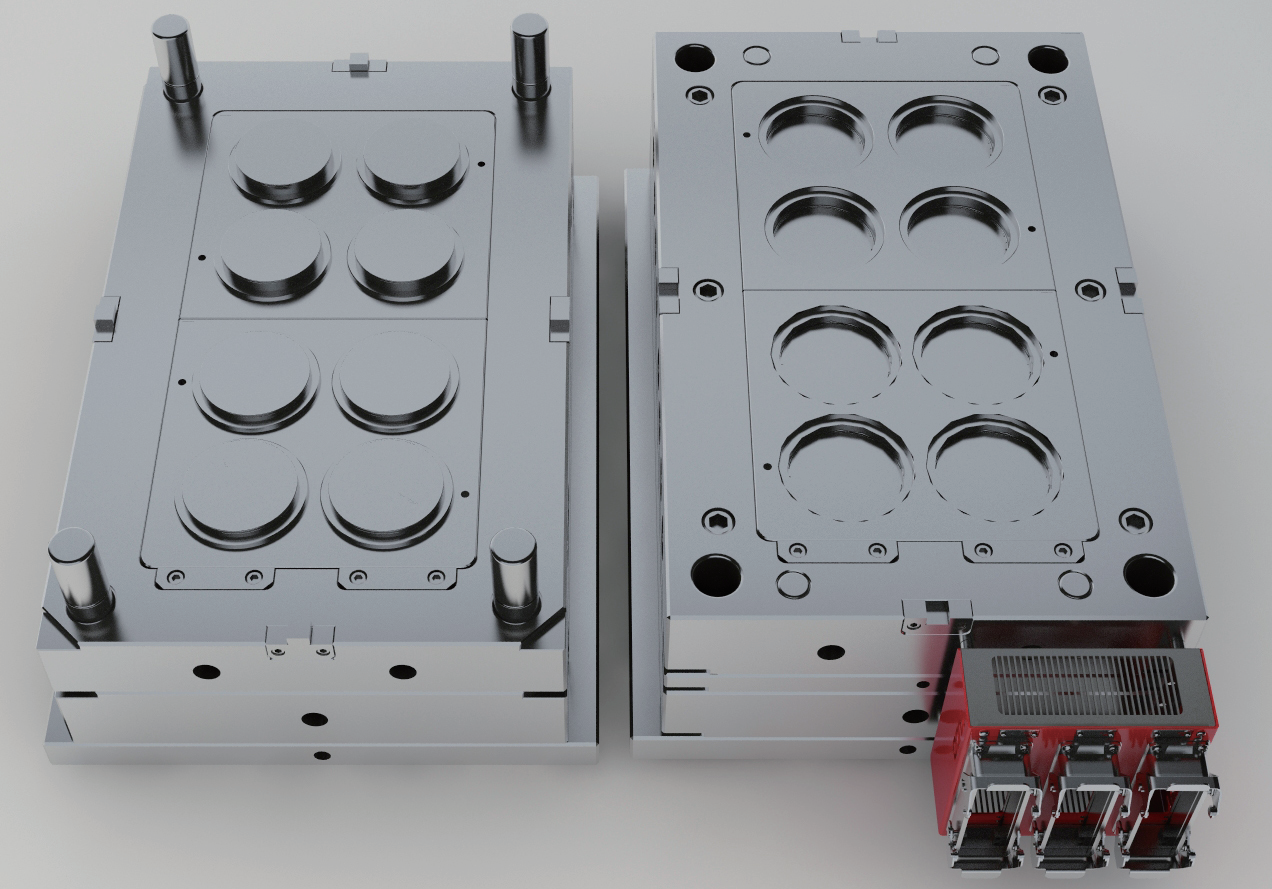

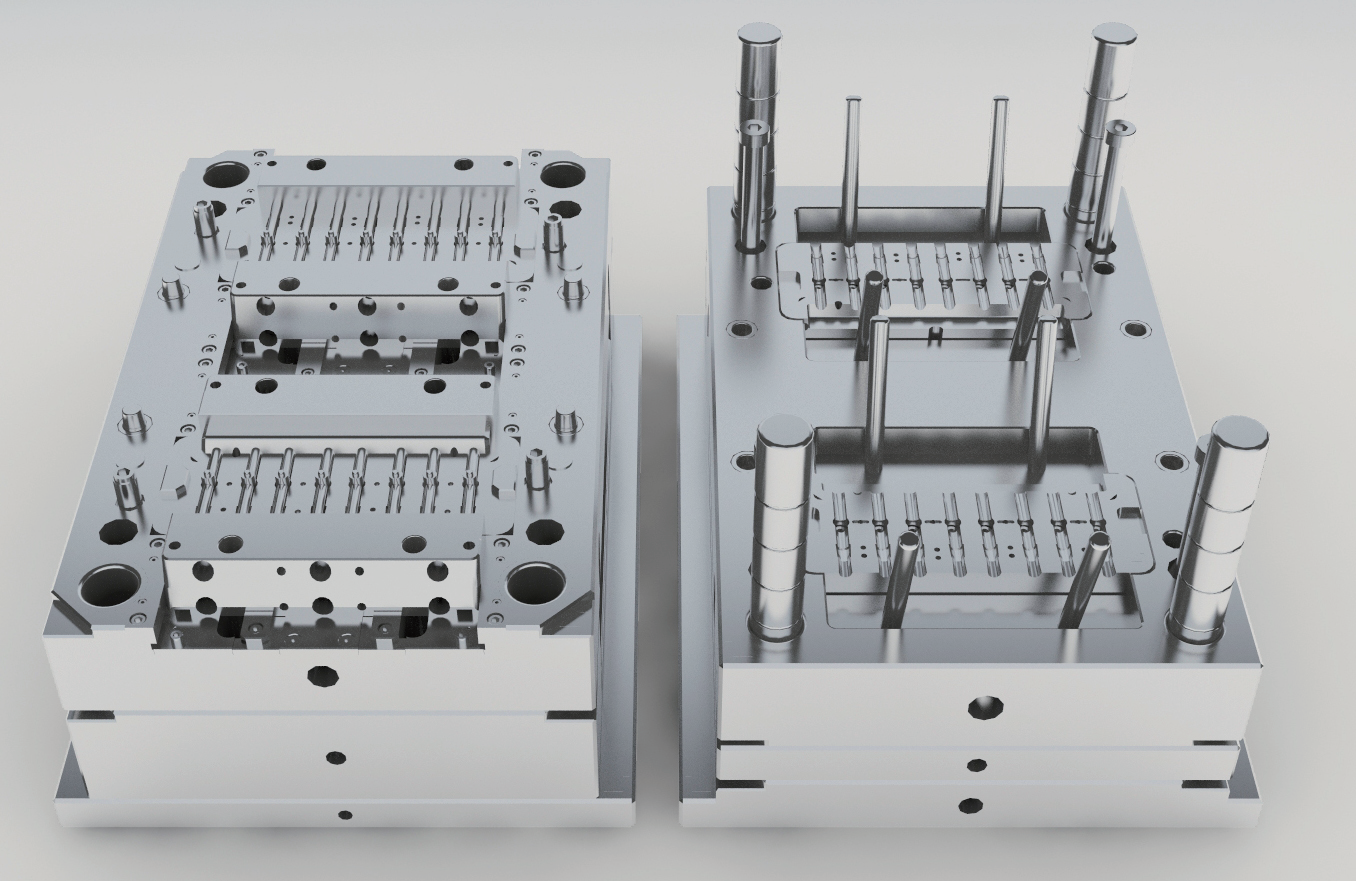

Injection molding services represent a cornerstone of modern manufacturing, offering a sophisticated and efficient method for producing high quality plastic components at scale. This process involves injecting molten plastic material into precisely engineered molds under high pressure, allowing for the creation of complex geometries and intricate details that would be impossible to achieve through other manufacturing methods. The technology employs advanced computer controlled systems that ensure precise temperature control, pressure regulation, and timing throughout the production cycle, resulting in consistent, high quality output. The service encompasses the entire production journey, from initial design consultation and prototype development to full scale manufacturing and quality assurance. Modern injection molding facilities utilize state of the art equipment capable of handling a diverse range of thermoplastic and thermosetting polymers, enabling the production of components for industries ranging from automotive and medical devices to consumer electronics and household goods. The process stands out for its ability to maintain tight tolerances and produce parts with excellent surface finishes, while simultaneously offering the flexibility to accommodate various material properties and design requirements.