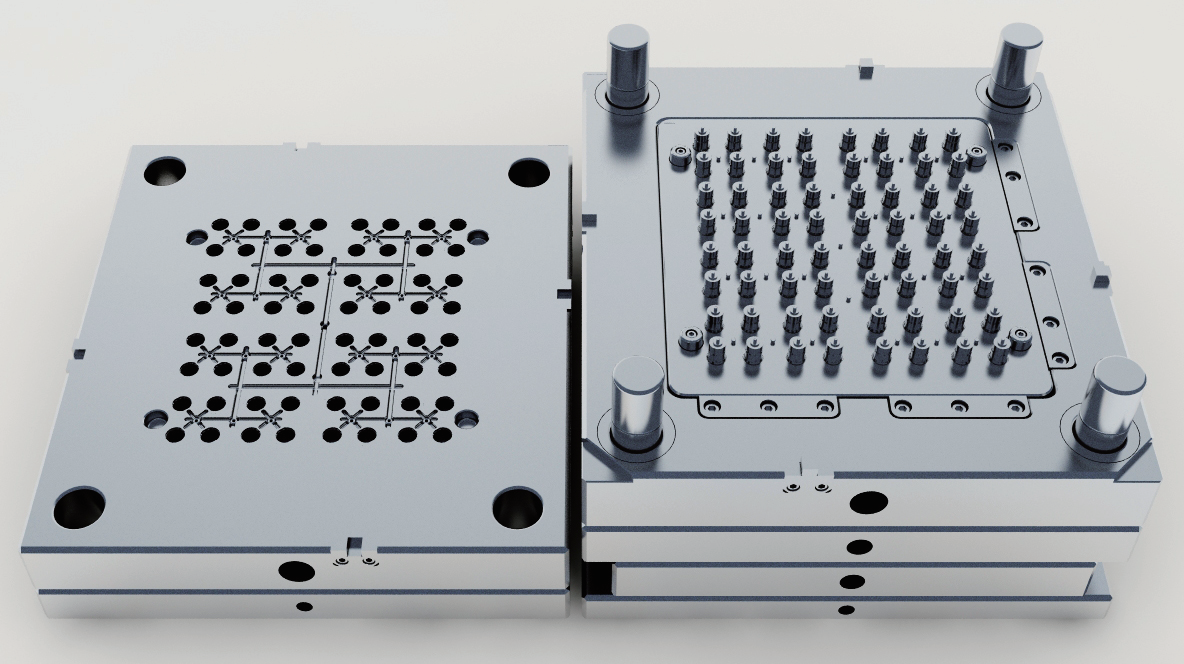

thermoset injection molding

Thermoset injection molding is a sophisticated manufacturing process that transforms thermosetting polymers into durable, high-performance parts through a carefully controlled injection and curing process. This advanced manufacturing method combines precise temperature control, pressure application, and material flow management to create components that exhibit exceptional mechanical properties and thermal stability. The process begins with heating the thermoset material to achieve optimal flow characteristics, followed by injection into a temperature-controlled mold cavity. Unlike thermoplastic molding, the material undergoes an irreversible chemical reaction during curing, resulting in a cross-linked molecular structure that provides superior strength, chemical resistance, and dimensional stability. The technology accommodates a wide range of thermoset materials, including epoxy, phenolic, and polyurethane compounds, making it suitable for producing components across various industries, from automotive and aerospace to electronic and medical applications. The process ensures consistent quality, minimal waste, and the ability to create complex geometries with tight tolerances.