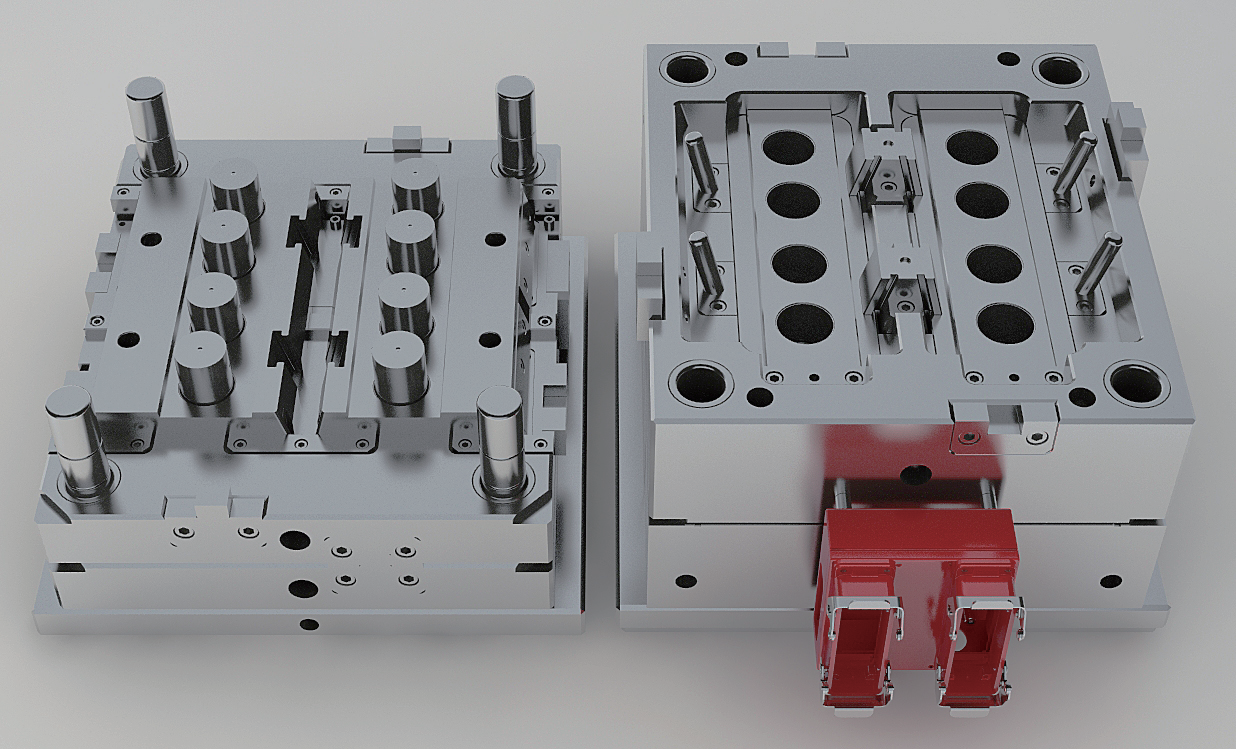

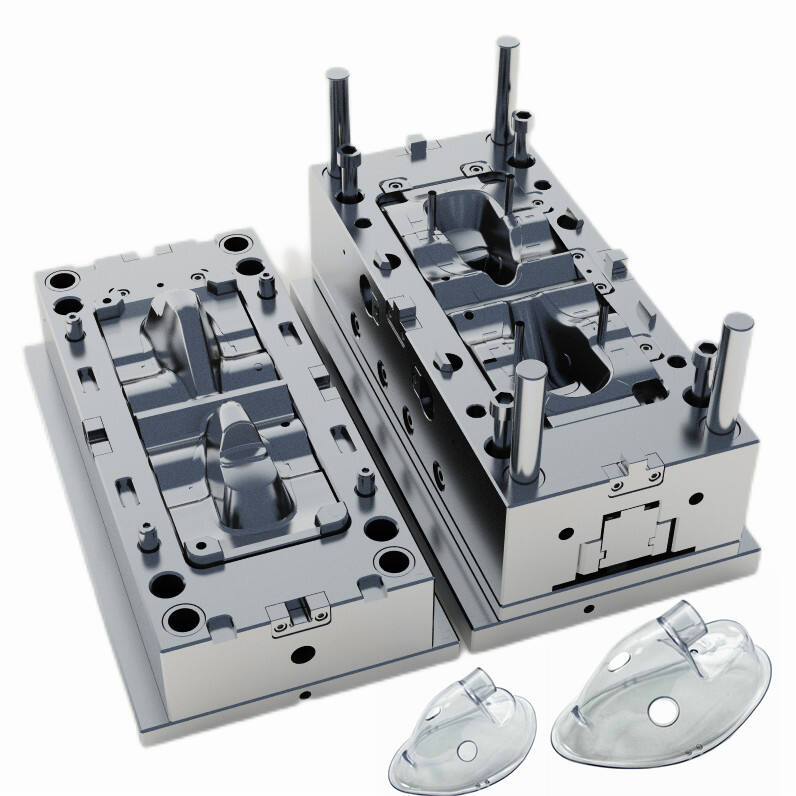

peek injection molding

Peek injection molding represents a sophisticated manufacturing process that utilizes polyetheretherketone (PEEK), a high-performance thermoplastic polymer, to create precise and durable components. This advanced manufacturing technique combines the exceptional properties of PEEK material with the versatility of injection molding to produce parts that excel in demanding environments. The process involves heating PEEK pellets to their melting point, approximately 343°C, and injecting the molten material into carefully designed molds under high pressure. The resulting components exhibit remarkable chemical resistance, excellent mechanical strength, and outstanding thermal stability. The technology enables the production of complex geometries with tight tolerances, making it particularly valuable in industries such as aerospace, medical devices, and automotive manufacturing. The process ensures consistent quality across large production runs while maintaining the material's inherent properties, including its resistance to wear, high-temperature performance, and compatibility with sterilization procedures. Additionally, peek injection molding allows for the integration of specific features like threads, snap-fits, and other functional elements directly into the molded parts, reducing the need for secondary operations and improving overall production efficiency.