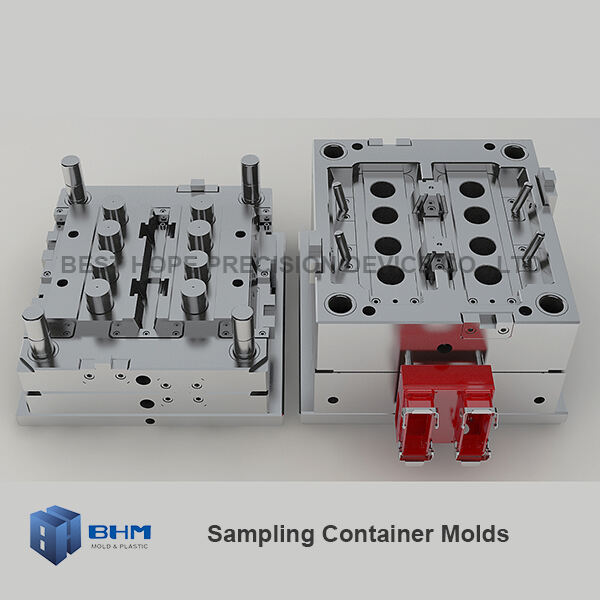

injection molding tooling

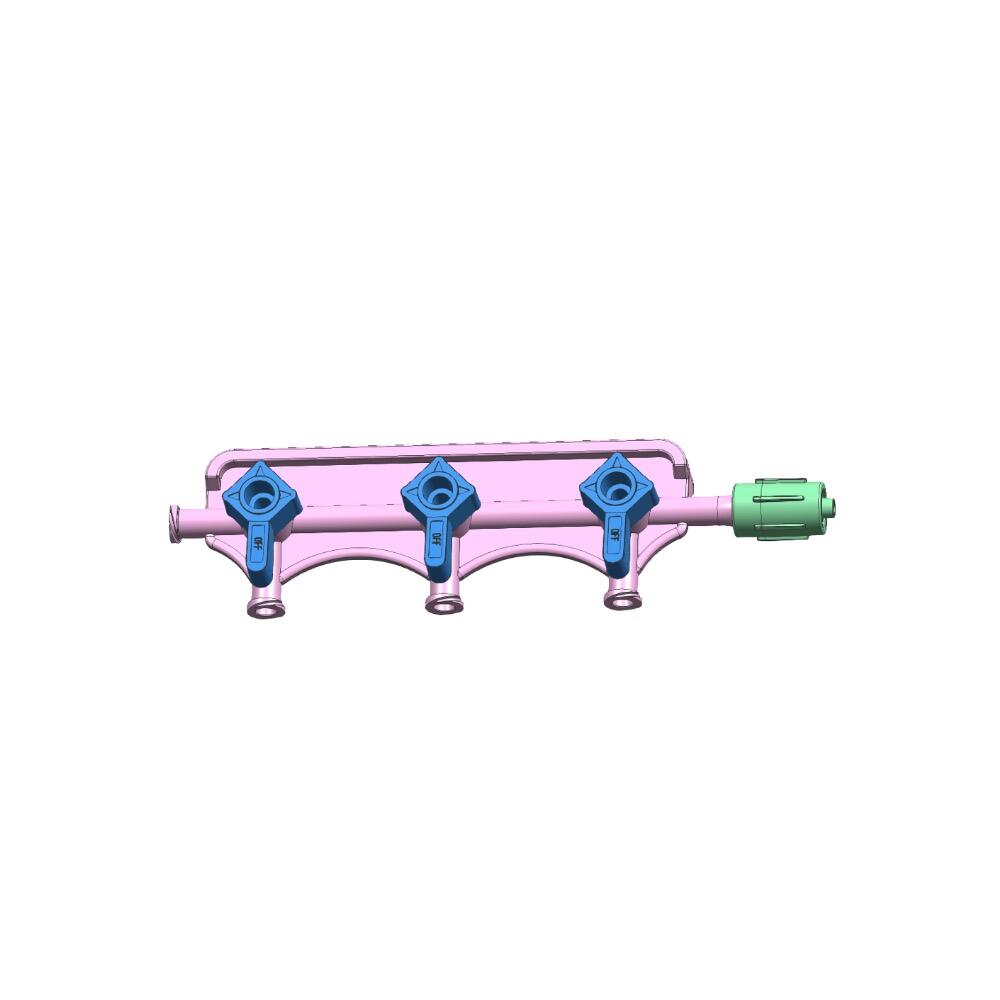

Injection molding tooling represents a crucial component in modern manufacturing processes, serving as the foundation for producing high-quality plastic parts with precision and consistency. This sophisticated equipment consists of two primary components: the injection mold and the tooling system that supports it. The mold itself is precisely engineered to create the desired part shape, while the tooling system manages critical functions such as alignment, cooling, and ejection. Advanced injection molding tooling incorporates innovative features like conformal cooling channels, which optimize temperature control throughout the production cycle, ensuring consistent part quality and reduced cycle times. The tooling system also includes sophisticated venting mechanisms to prevent air traps and ensure complete cavity filling. Modern injection molding tools often feature modular designs, allowing for quick changeovers and efficient maintenance. These systems can accommodate various materials, from standard thermoplastics to engineering-grade polymers, making them versatile for diverse applications across automotive, medical, consumer goods, and electronics industries. The tooling's precision engineering enables the production of complex geometries with tight tolerances, while its robust construction ensures longevity and reliability in high-volume production environments.