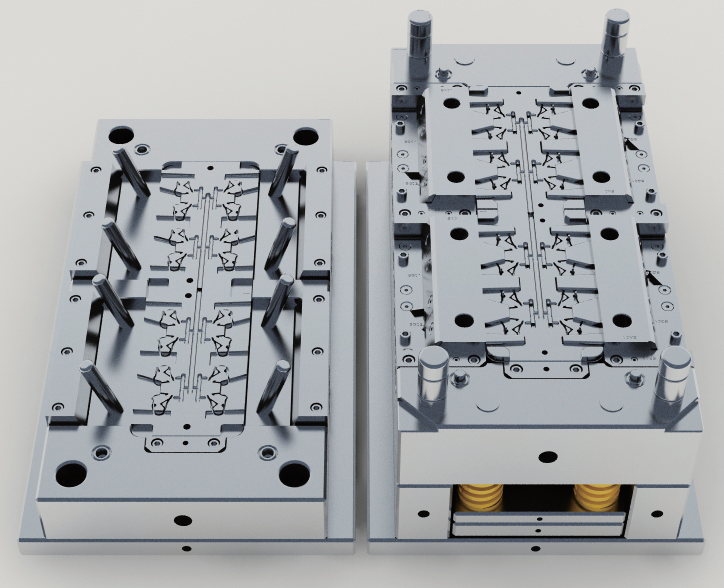

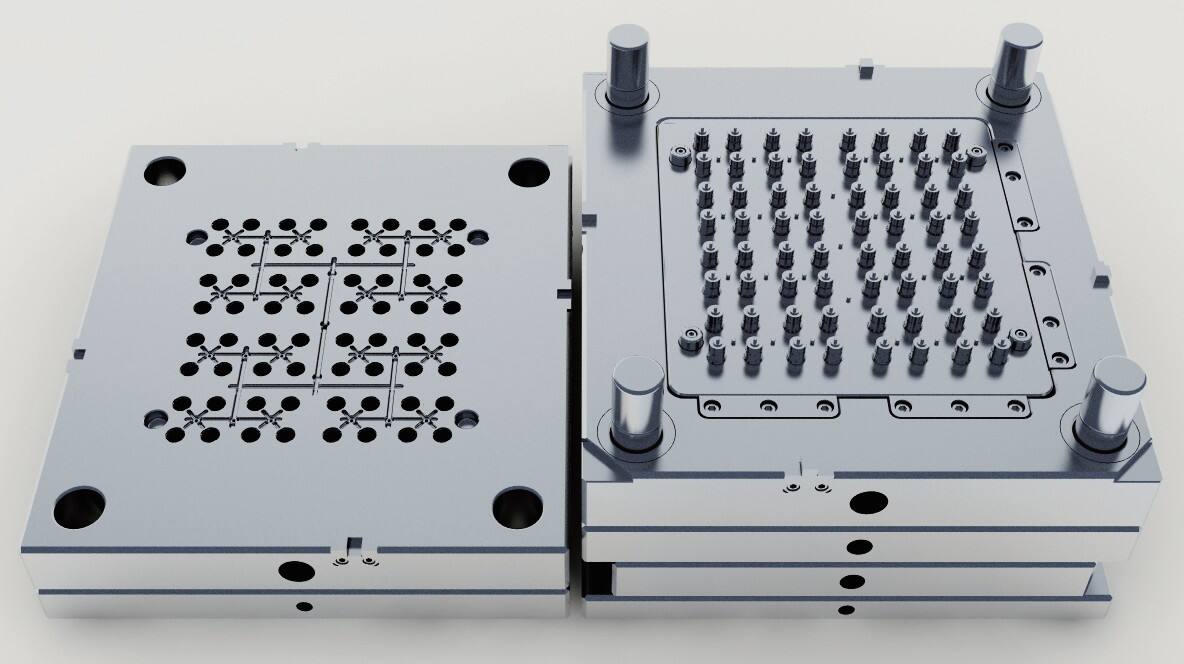

medical mold for sale

Medical molds for sale represent cutting-edge manufacturing solutions designed specifically for the healthcare industry. These precision-engineered tools are essential for producing various medical devices, components, and equipment with exceptional accuracy and consistency. The molds incorporate advanced materials and sophisticated design features that ensure compliance with stringent medical industry standards, including ISO 13485 certification requirements. They are manufactured using state-of-the-art CNC machining and EDM technology, enabling the production of complex geometries and micro-detailed components essential for medical applications. These molds are specifically designed to work with medical-grade materials, including various thermoplastics and silicone, ensuring biocompatibility and sterilization capability. The molds feature optimized cooling channels, precise gate locations, and advanced venting systems to guarantee consistent part quality and reduced cycle times. They are particularly suited for manufacturing items such as medical device housings, surgical instruments, diagnostic equipment components, and various disposable medical supplies. Each mold undergoes rigorous quality control processes and validation procedures to ensure long-term reliability and consistent performance in medical product manufacturing operations.